A kind of liposome freeze-dried composition and application

A liposome freeze-drying and composition technology, which is applied in cosmetic liposomes and cosmetics fields, can solve the problems of not considering the shape of the final product, failing to maintain the fine structure, and difficult to form the appearance, so as to achieve fine appearance, maintain the fine structure, Strong appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment one: the preparation method of propylene glycol alginate liposome freeze-dried composition

[0044](1) Weigh 8-588 parts of propylene glycol alginate liposome, 24-533 parts of thickener, and 133-930 parts of filler, add to water, fully swell, and mix well.

[0045] (2) Transfer the liquid obtained in step (1) to a mold, freeze until completely solidified, and demould to obtain a frozen geometric figure.

[0046] (3) Transfer the frozen geometric figure obtained in step (2) to the sublimation chamber of the freeze-drying equipment, and sublimate under reduced pressure until the drying is complete.

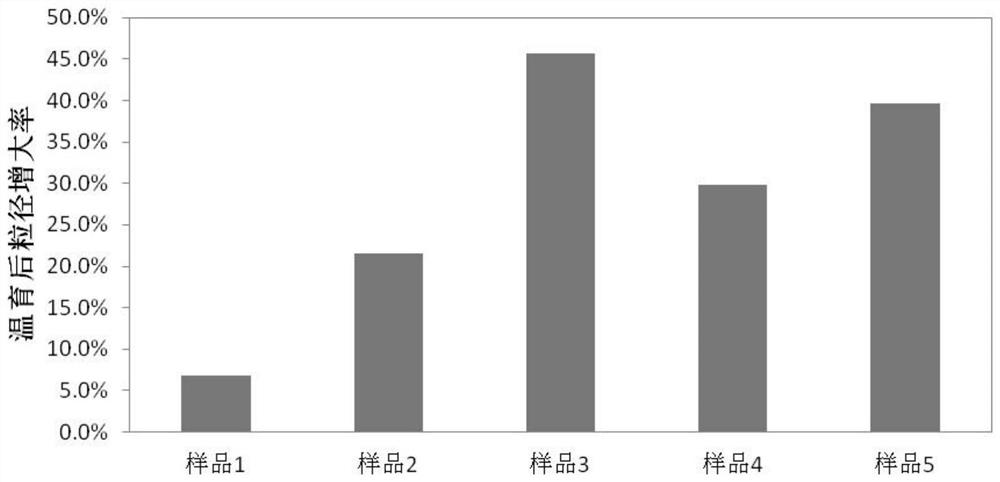

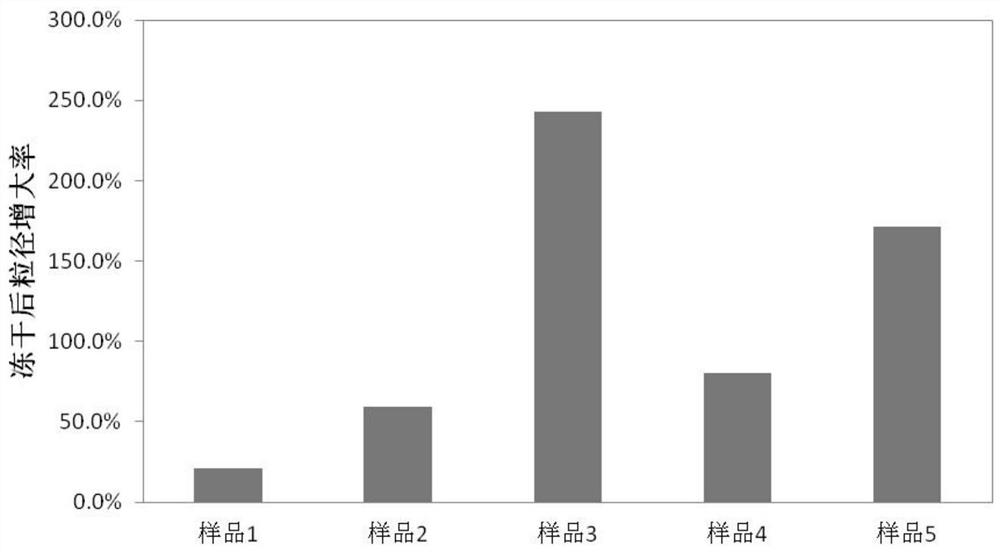

[0047] Liposome stability comparison in liquid state: take each liposome suspension, measure the original average particle size P1; The sample after incubation was 2 mL, and the average particle size P2 after incubation was measured; the particle size increase rate was calculated = (P2-P1) / P1*100%, and the larger the value, the worse the stability.

[0048] Compa...

Embodiment 2

[0052] Embodiment two: the liquid stability and freeze-dried stability comparison of different liposomes

[0053] Sample 1, propylene glycol alginate liposome (PGA liposome): (1) Weigh 1 g of hydrogenated lecithin, dissolve it completely in 18 ml of ether and 2 ml of chloroform, and it is an oil phase; weigh 0.1 g of propylene glycol alginate, In 99.9g of water (0.1% propylene glycol alginate aqueous solution), heat and swell to form the water phase; (2) take 10g of the water phase (containing 0.1% propylene glycol alginate) and slowly add it to the oil phase, ultrasonically, to obtain W / O Emulsion; (3) Add 90g of water phase to the W / O suspension in (2), ultrasonicate for 5min to obtain W / O / W emulsion; (4) Remove the organic solvent by rotary evaporation, add water to 100ml, pass through 0.22um filter membrane to obtain the suspension of propylene glycol alginate liposome.

[0054] Sample 2, blank liposome + external water phase propylene glycol alginate (blank liposome + ex...

Embodiment 3

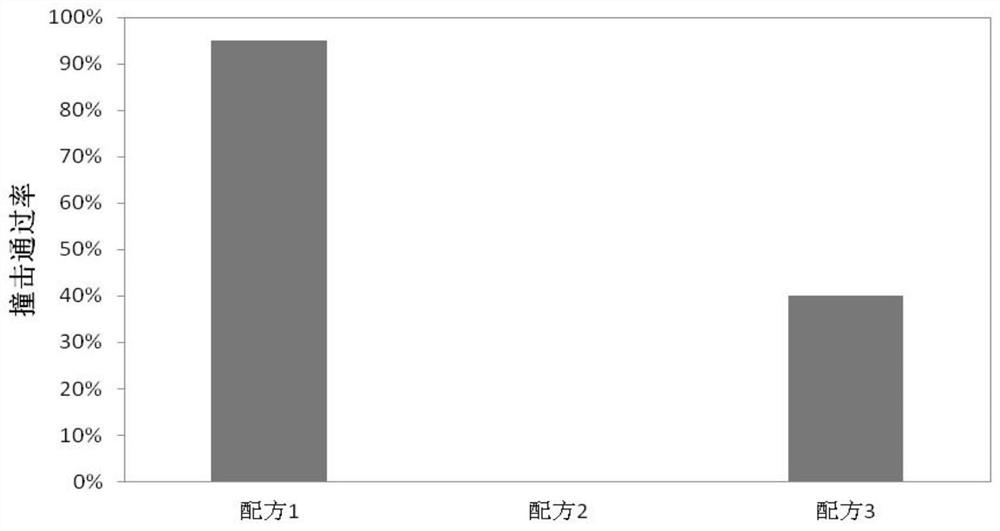

[0066] Embodiment 3: Structural toughness and texture comparison of different liposome freeze-dried compositions

[0067] Table 2: Formulation table of four different components

[0068]

[0069] Weigh 8g of hydrogenated lecithin, add absolute ethanol, heat and dissolve completely, and become the oil phase; weigh 2g of propylene glycol alginate, dissolve it in 998g of water (0.2% propylene glycol alginate), and swell it to become the water phase; the oil phase is rotary evaporated Remove ethanol to form a thin film; add 1000 g of water phase, and ultrasonicate for 5 minutes to obtain a suspension of PGA liposomes with a solid content of about 1%.

[0070] Formula 1, the formula of the present invention: take by weighing liposome suspension 250g (equivalent to liposome 2.5g), thickener, filler three kinds of components, mix, add water to be settled to 400ml water, stir to swell Completely; fill rose silicone molds, freeze completely at -30°C, take out the mold; transfer the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com