Preparation method of catalyst for ethylene preparation through oxidative dehydrogenation of ethane

A technology of oxidative dehydrogenation and catalyst, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, carbon compound catalyst, etc. Contribute little to other issues, and achieve the effect of benefiting industrial scale-up, reducing concentration difference, and reducing the amount of metal used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

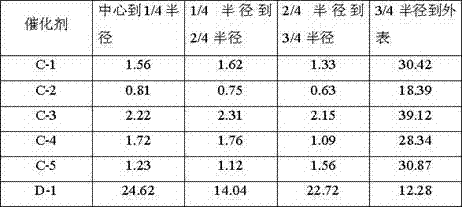

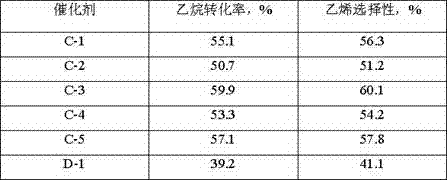

Embodiment 1

[0023] The spent hydrotreating catalyst (MoCo / Al 2 o 3 ), the oil on the catalyst surface was removed by petroleum ether extraction, dried at 110°C for 8 h, and the obtained catalyst was calcined at 450°C for 4 h to obtain catalyst precursor A, wherein Mo accounted for 7.6wt% by weight of catalyst precursor A in terms of elements, Co accounts for 2.2wt% of the weight of the catalyst precursor A in terms of elements, Ni accounts for 2.3wt% of the weight of the catalyst precursor A in terms of elements, and V accounts for 2.1wt% of the weight of the catalyst precursor A in terms of elements; Activated in a mixed atmosphere of hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction conditions are 450°C, 0.2MPa (absolute pressure), and the reduction time is 4h; 15g polyethylene glycol and 16.3g nickel nitrate are dissolved in 200mL deionized In water, solution B was obtained, and mixed with 60g of furfural solution with a mass fraction of 40%, then added t...

Embodiment 2

[0025] The spent hydrotreating catalyst (MoCo / Al 2 o 3), the oil on the catalyst surface was removed by petroleum ether extraction, dried at 110°C for 8 h, and the obtained catalyst was calcined at 450°C for 4 h to obtain catalyst precursor A, wherein Mo accounted for 5.2wt% by weight of catalyst precursor A in terms of elements, Co accounts for 1.4wt% of the weight of the catalyst precursor A in terms of elements, Ni accounts for 1.7wt% of the weight of the catalyst precursor A in terms of elements, and V accounts for 1.5wt% of the weight of the catalyst precursor A in terms of elements; Activated in a mixed atmosphere of hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction conditions are 450°C, 0.2MPa (absolute pressure), and the reduction time is 4h; 10g polyethylene glycol and 10.7g nickel nitrate are dissolved in 200mL deionized In water, solution B was obtained, and mixed with 60g of furfural solution with a mass fraction of 40%, then added to...

Embodiment 3

[0027] The spent hydrotreating catalyst (MoCo / Al 2 o 3 ), the oil on the catalyst surface was removed by petroleum ether extraction, dried at 110°C for 8 h, and the obtained catalyst was calcined at 450°C for 4 h to obtain catalyst precursor A, wherein Mo accounted for 9.8wt% by weight of catalyst precursor A in terms of elements, Co accounts for 2.8wt% of the weight of the catalyst precursor A in terms of elements, Ni accounts for 2.7wt% of the weight of the catalyst precursor A in terms of elements, and V accounts for 2.6wt% of the weight of the catalyst precursor A in terms of elements; Activated in a mixed atmosphere of hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction conditions are 450°C, 0.2MPa (absolute pressure), and the reduction time is 4h; 21g polyethylene glycol and 22.1g nickel nitrate are dissolved in 200mL deionized In water, solution B was obtained, and mixed with 60g of furfural solution with a mass fraction of 40%, then added t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com