Tailing, alkali slag and ore slag cementing material stirring device and preparation process

The technology of a stirring device and cementitious material is applied in the field of slag cementitious material stirring device and preparation process, tailings, building materials, and alkali slag, which can solve the problems of environmental pollution and high cost, and achieve high utilization rate and high fluidity. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

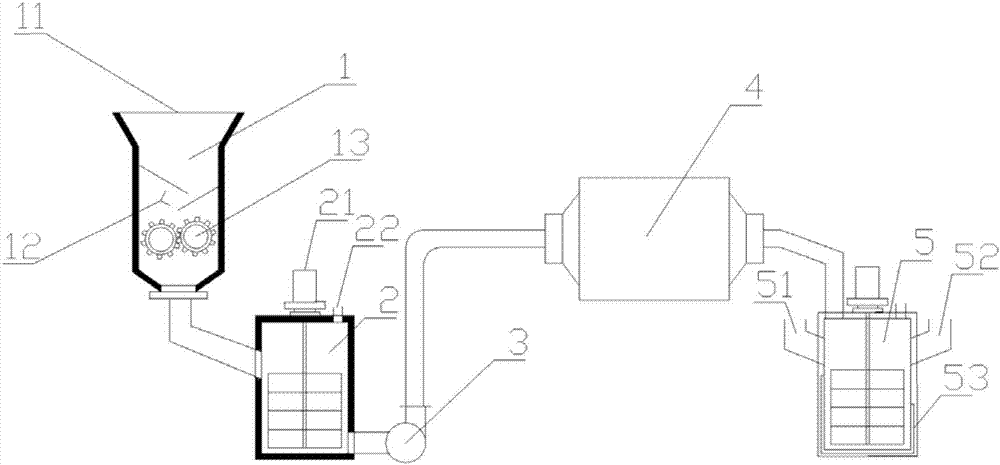

Image

Examples

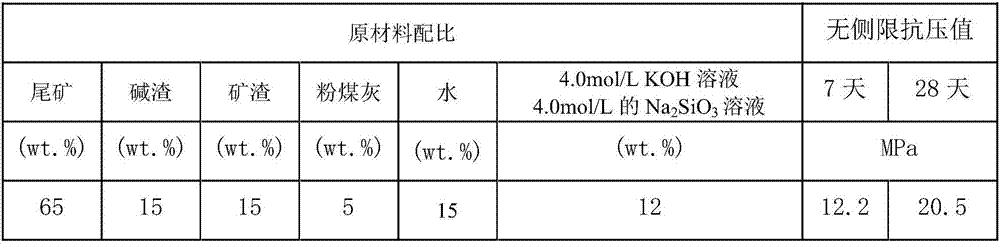

Embodiment 1

[0033] Take the actual required amount of alkali slag, slag, fly ash and Anshan iron ore tailings for construction projects, and their mass fractions are 15%, 15%, 5%, and 65% respectively; the mass fraction of the excitation solution is the total amount of the above mixture 10% (mass), by molar concentration of 4.0mol / L of KOH and 4.0mol / L of Na 2 SiO 3 The solution was mixed 1:1 as the excitation solution. First, the alkali slag is crushed, then injected into the aqueous solution according to the mass ratio of 1:1, stirred and ground to obtain the alkali slag mortar, and then the measured excitation liquid is evenly added to the alkali slag mortar, stirred evenly at a slow speed, and then the slag is evenly added , fly ash, after stirring evenly, add the measured Anshan-type iron ore tailings, stir evenly, and control the discharge temperature to 50°C through the mixing device to obtain tailings, alkali slag, and slag cementitious materials, and then mix them Inject it int...

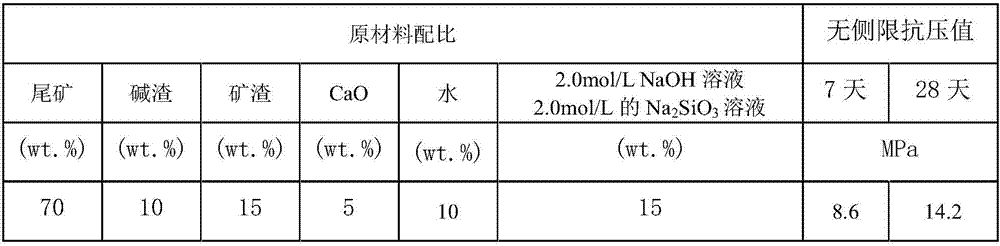

Embodiment 2

[0039] Take the actual amount of alkali slag, slag, CaO and Anshan iron ore tailings used in the construction project, and the mass fractions are 10%, 15%, 5%, and 70% respectively; the mass fraction of the excitation solution is 15% of the total amount of the above mixture (quality), by molar concentration is the NaOH of 2.0mol / L and the Na of 2.0mol / L 2 SiO 3 The solution was mixed 1:1 as the excitation solution. First, the alkali slag is crushed, then injected into the aqueous solution according to the mass ratio of 1:1, stirred and ground to obtain the alkali slag mortar, and then the measured excitation liquid is evenly added to the alkali slag mortar, stirred evenly at a slow speed, and then the slag is evenly added , CaO, after stirring evenly, add the measured Anshan-type iron ore tailings, stir evenly, and control the discharge temperature to 40°C through the mixing device to obtain tailings, alkali slag, and slag cementitious materials, and then inject them into 40m...

Embodiment 3

[0045] Get the actual required amount of alkali slag, slag, fly ash and vanadium-titanium magnetite tailings, and its mass fractions are respectively 10%, 15%, 5%, and 70%; the mass fraction of the excitation solution is the total amount of the above mixture. Amount of 15% (mass), by the molar concentration of 1.0mol / L of NaOH and 1.0mol / L of Na 2 SiO 3 The solution was mixed 1:1 as the excitation solution. First, the alkali slag is crushed, then injected into the aqueous solution according to the mass ratio of 1:1, stirred and ground to obtain the alkali slag mortar, and then the measured excitation liquid is evenly added to the alkali slag mortar, stirred evenly at a slow speed, and then the slag is evenly added , fly ash, after stirring evenly, add the measured vanadium-titanium-magnetite tailings, stir evenly, and control the discharge temperature to 50°C through the mixing device to obtain tailings, alkali slag, and slag cementitious materials, and then put It is poured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com