Preparation method of tin based nano composite material for detecting low concentration acetone gas

A nano-composite material and low-concentration technology, which is applied in the field of preparation of tin-based nano-composite materials, can solve the problems of large equipment occupation, poor selectivity and stability, and low sensitivity, and achieve fast response and recovery speed, accurate and detailed data, Good shape of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

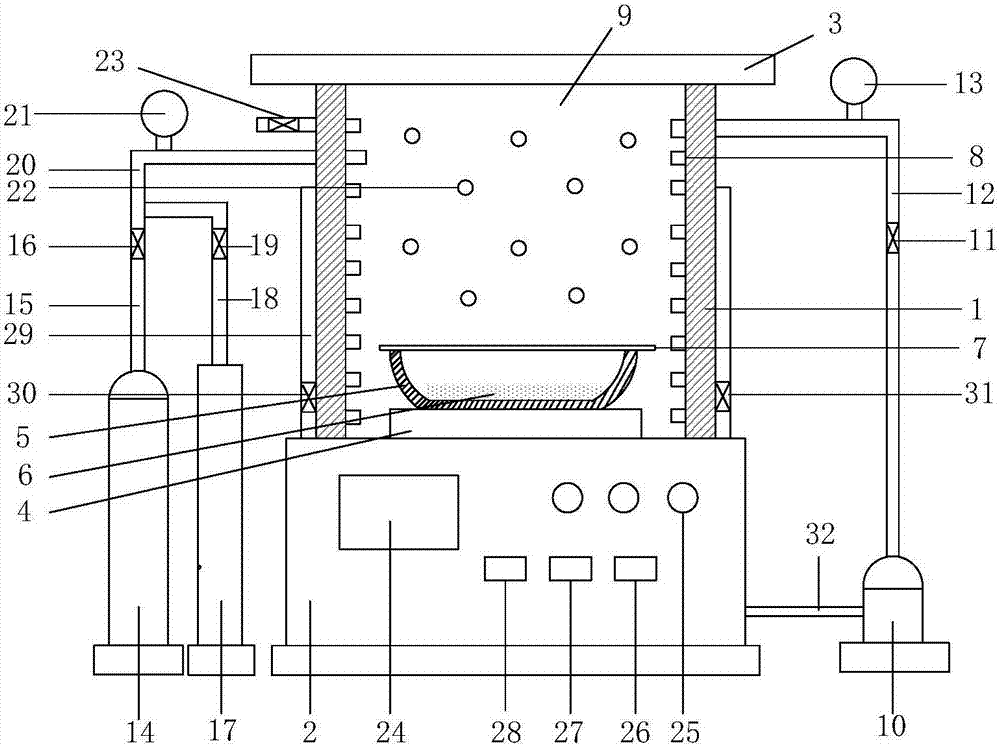

[0066] The present invention will be further described below in conjunction with accompanying drawing:

[0067] figure 1 Shown, for tin-based Pr 6 o 11 / Sn 3 o 4 / SnO 2 The heat treatment state diagram of nanocomposite materials, the position of each part must be correct, the proportion should be proportioned, and the operation should be done in sequence;

[0068] Quantities of chemicals used in preparation are determined in pre-set ranges in grams, milliliters, centimeters 3 is the unit of measurement.

[0069] The heat treatment of tin-based nanocomposites is carried out in a vacuum microwave sintering furnace, which is completed under vacuum, oxygen + nitrogen, microwave heating, and external water circulation cooling;

[0070] The vacuum microwave sintering furnace 1 is a vertical type. The bottom of the vacuum microwave sintering furnace 1 is an electric control box 2, the top is a furnace cover 3, and the interior is a furnace chamber 9; 4 Place a quartz containe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com