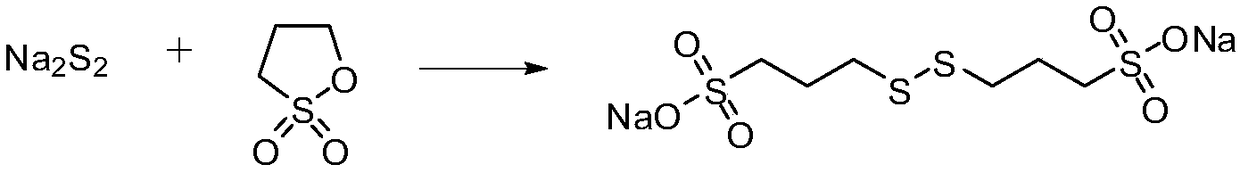

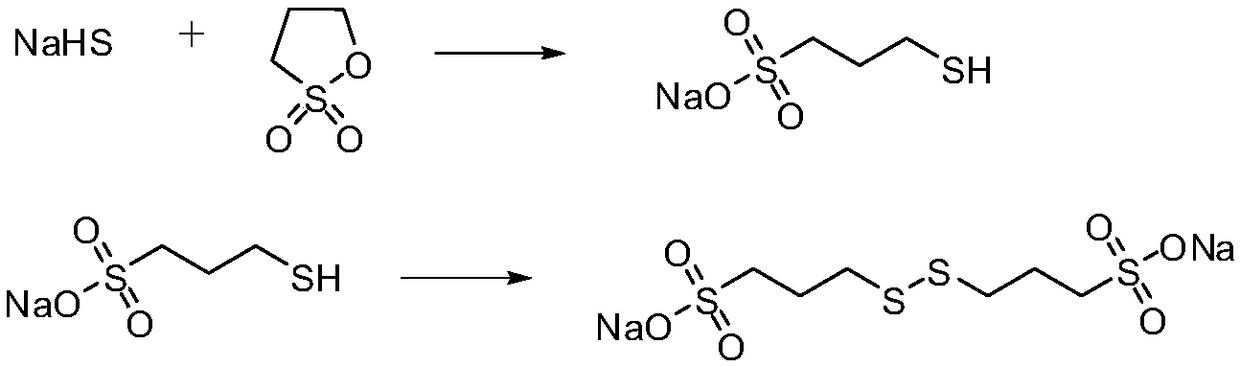

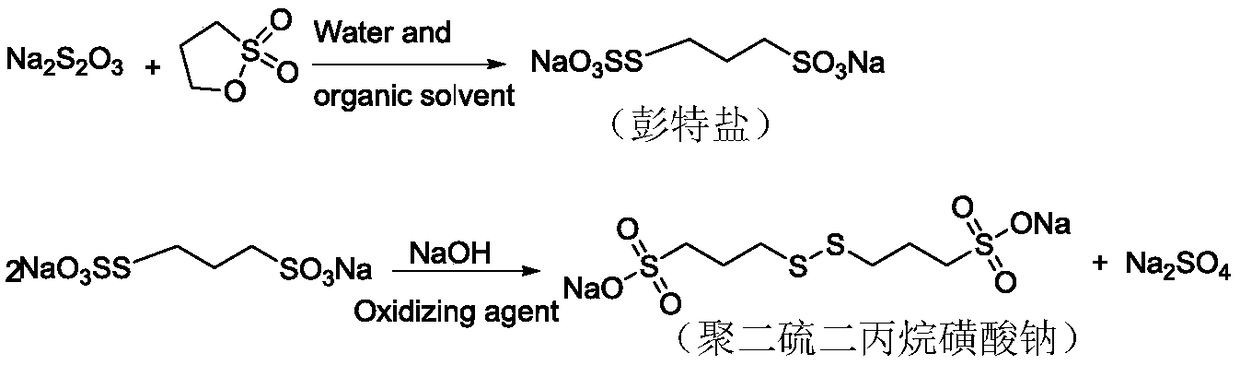

Synthetic process of sodium polydithiodipropane sulfonate

A technology of sodium polydisulfide dipropane sulfonate and synthesis process, which is applied in the synthesis field of sodium polydisulfide dipropane sulfonate, can solve the problems of many steps, high production cost, difficulty in obtaining high-purity products, etc., and achieves easy access to raw materials. the effect of fewer synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The synthetic technique of sodium polydithiodipropane sulfonate, this synthetic technique comprises the following steps:

[0039] 1) Synthesis of Pent’s salt: Add 79g (0.5mol) sodium thiosulfate and 300mL methanol into a 500mL four-neck flask and stir evenly, cool down to 20°C, slowly add 61g (0.5mol) 1,3-propanesulfone dropwise For ester, control the dropwise addition temperature at 20-30°C. After the dropwise addition, continue to react at 20°C for 2 hours to obtain Pent salt;

[0040] 2) Preparation of sodium dithiodipropane sulfonate: after adding 30% sodium hydroxide to the prepared Penter's salt in step 1) to adjust the pH value to 10, add 22.5g (0.25mol) tert-butyl hydroperoxide, Raise the temperature to 55°C for 4 hours, then lower the temperature to 5°C, filter and separate the solid sodium sulfate, and at the same time, concentrate the filtrate until the solid precipitates, filter and dry at 70-80°C to obtain polydithiodipropanesulfonic acid sodium.

[0041]...

Embodiment 2

[0043] The synthetic technique of sodium polydithiodipropane sulfonate, this synthetic technique comprises the following steps:

[0044] 1) Synthesis of Penter's salt: Add 79g (0.5mol) sodium thiosulfate, 200mL isopropanol and 100mL water into a 500mL four-necked bottle and stir evenly, cool down to 20°C, slowly add 61g (0.5mol)1,3 - Propane sultone, control the dropwise addition temperature at 20-30°C, after the dropwise addition, continue to react at 20°C for 2 hours to obtain Pent's salt;

[0045] 2) Preparation of sodium polydisulfide dipropane sulfonate: after adding 30% sodium hydroxide to the prepared Penter's salt in step 1) to adjust the pH value to 10, add 30g (0.25mol) of 28% super Hydrogen oxide, heat up to 50°C and react for 4 hours, then cool down to 5°C, filter and separate solid sodium sulfate, at the same time, concentrate the filtrate until solid precipitates, filter and dry at 70-80°C to obtain polydisulfide Sodium Propane Sulfonate.

[0046] The yield of ...

Embodiment 3

[0048] The synthetic technique of sodium polydithiodipropane sulfonate, this synthetic technique comprises the following steps:

[0049] 1) Synthesis of Penter's salt: Add 79g (0.5mol) sodium thiosulfate, 250mL isopropanol and 50mL water into a 500mL four-necked bottle and stir evenly, cool down to 20°C, slowly add 61g (0.5mol)1,3 - Propane sultone, control the dropwise addition temperature at 20-30°C, after the dropwise addition, continue to react at 20°C for 2 hours to obtain Pent's salt;

[0050] 2) Preparation of sodium polydithiodipropane sulfonate: after adding 30% sodium hydroxide to the prepared Penter's salt in step 1) to adjust the pH value to 10, continue to feed oxygen, raise the temperature to 60°C and react for 4 hours, Then lower the temperature to 5°C, filter and separate the solid sodium sulfate, and at the same time, concentrate the filtrate until the solid precipitates, filter and dry at 70-80°C to obtain sodium polydithiodipropanesulfonate.

[0051] The yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com