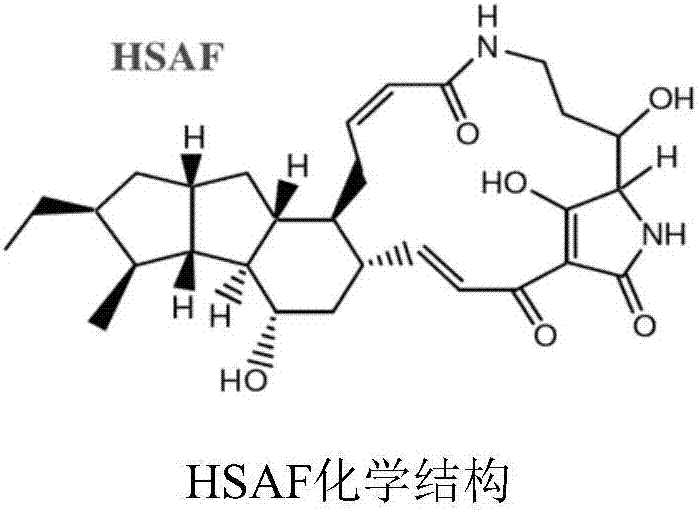

Method for quickly and efficiently extracting active antimicrobial substance HSAF (Heat Stable Antifungal Factor) in fermentation liquor

A technology of antibacterial substances and fermented liquid, applied in the field of separation engineering, can solve the problems of HSAF industrial production difficulties, easy emulsification of the system, increase of production process, etc., and achieve the effects of shortening extraction time, easy stratification, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

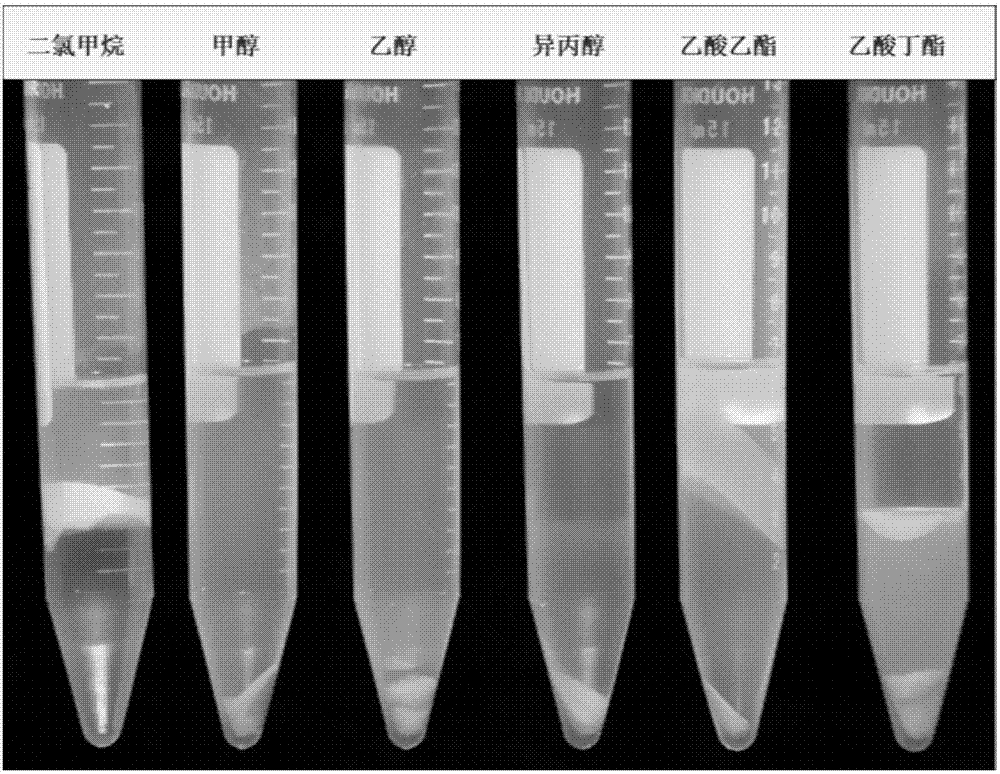

[0033] Embodiment 1: the influence of different organic solvents on the extraction of HSAF in the fermented liquid

[0034] Draw 3mL of the fermentation broth into a 15mL centrifuge tube, add concentrated hydrochloric acid dropwise until the pH is 3.0; add 3mL of organic solvent (Table 1) to the mixture; place it on a vortex mixer at 2000rpm for 1min to make the organic solvent and the fermentation broth fully Contact; centrifuge at 8000rpm for 5min to separate the fermentation broth and the organic solvent into two phases, the supernatant is the HSAF organic solvent layer, draw 1mL to dry and add 500μL of methanol to dissolve and then detect its content by HPLC.

[0035] Detection conditions are: reversed-phase column: InterSustainSwift C18 5μm, 250×4.6mm, mobile phase: solution A (0.025% TFA in water) and solution B (0.025% TFA in acetonitrile), flow rate: 1mL / min; injection volume: 20μL , UV absorption value: 318nm; Injection program: 0-10min, solution B from 5% to 25%; 25m...

Embodiment 2

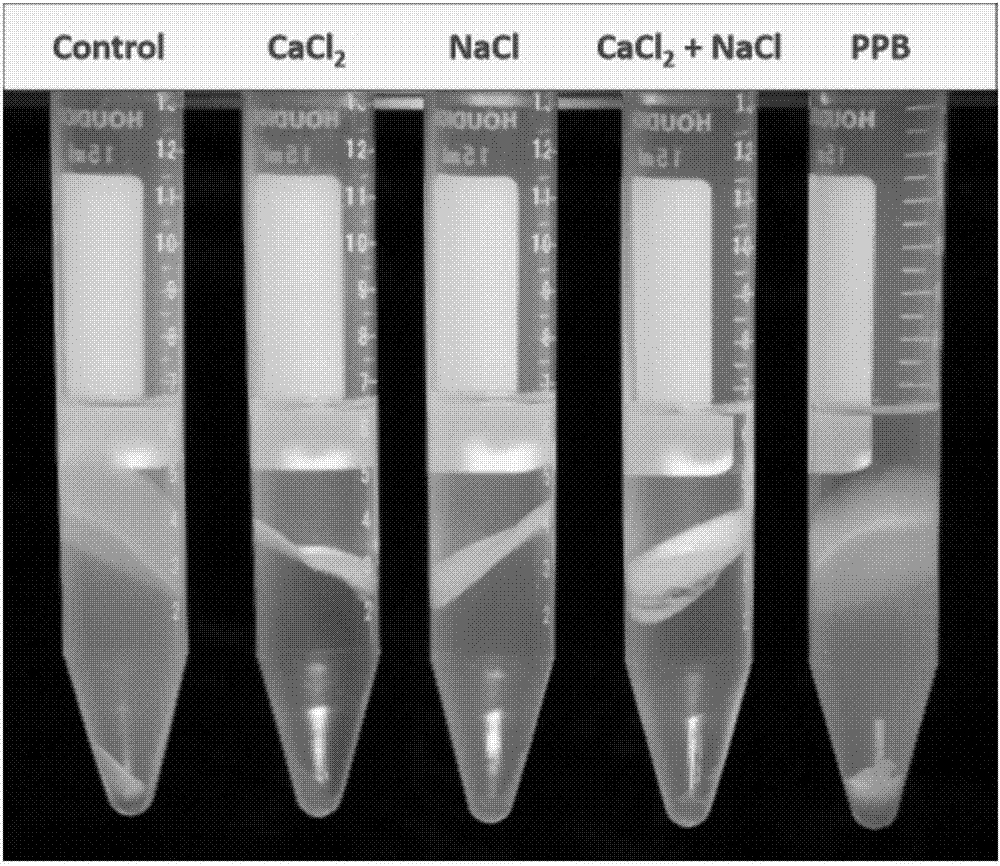

[0039] Embodiment 2: adding CaCl 2 Breaking the emulsified extraction of HSAF in the fermentation broth

[0040] Draw 3mL of fermentation broth into a 15mL centrifuge tube, add concentrated hydrochloric acid dropwise to pH 3.5; add 0.5g CaCl 2 Finally, shake it gently to make it fully dissolved; add 3mL ethyl acetate solvent to the mixture; place it on a vortex mixing oscillator at 2000rpm for 1min to make the extractant fully contact with the fermentation broth; centrifuge at 8000rpm for 5min to make the organic phase and The water phase is separated, and the supernatant is drawn to be the HSAF extract, and its content is detected by HPLC, and other conditions are the same as in Example 1.

[0041] Depend on figure 2 As can be seen from Table 2, CaCl 2 It can effectively break the emulsification phenomenon produced in the extraction process, and can increase the content of HSAF in the extract (336.8mg / L). At the same time, the HSAF content obtained after the full extract...

Embodiment 3

[0042] Embodiment 3: adding NaCl to break the HSAF in the emulsified extraction fermented liquid

[0043] Draw 3mL of fermentation broth into a 15mL centrifuge tube, add concentrated hydrochloric acid dropwise until the pH is 4.0; put in 0.6g NaCl, shake gently to dissolve it fully; add 3mL ethyl acetate solvent to the mixture; place in a vortex mixer React at 2000rpm for 1min to fully contact the extractant with the fermentation broth; centrifuge at 8000rpm for 5min to separate the fermentation broth and the organic solvent into two phases, the supernatant is the HSAF extract, draw 1mL to dry and add 500μL of methanol to dissolve and follow the steps in Example 1 The middle scheme was used to detect its content.

[0044] Depend on figure 2 It can be seen from Table 2 that NaCl can effectively break the emulsification phenomenon produced during the extraction process, and can increase the content of HSAF in the extract (343.6mg / L). At the same time, the HSAF content obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com