A kind of polyaryletherketone cable material resin and its synthesis method

A cable material resin, polyaryl ether ketone technology, applied in the field of polyaryl ether ketone cable material resin and its synthesis, can solve the problems of complex preparation process requirements, reduce cable reliability, increase product cost, etc., and achieve multiple cross-linking points. , The effect of improving thermal stability and physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

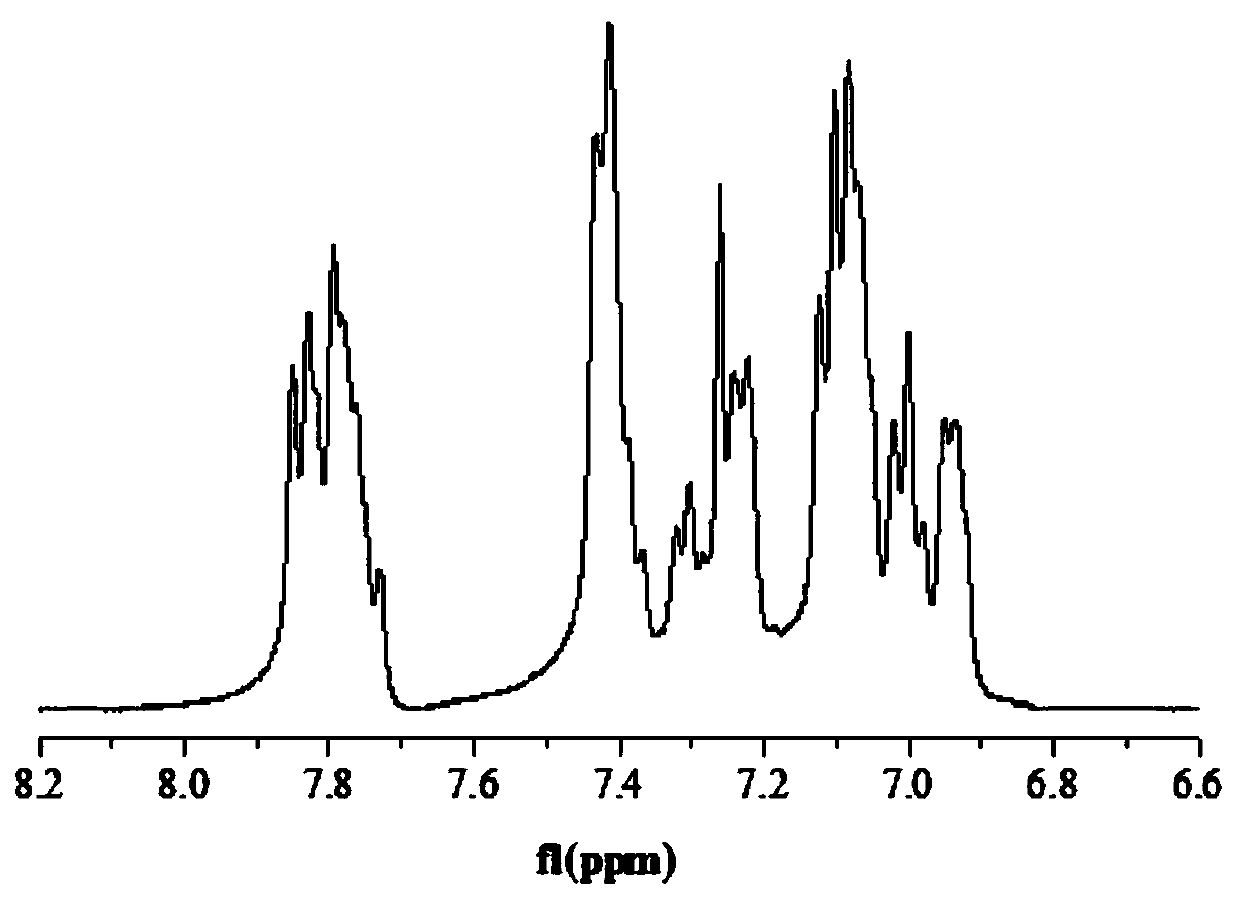

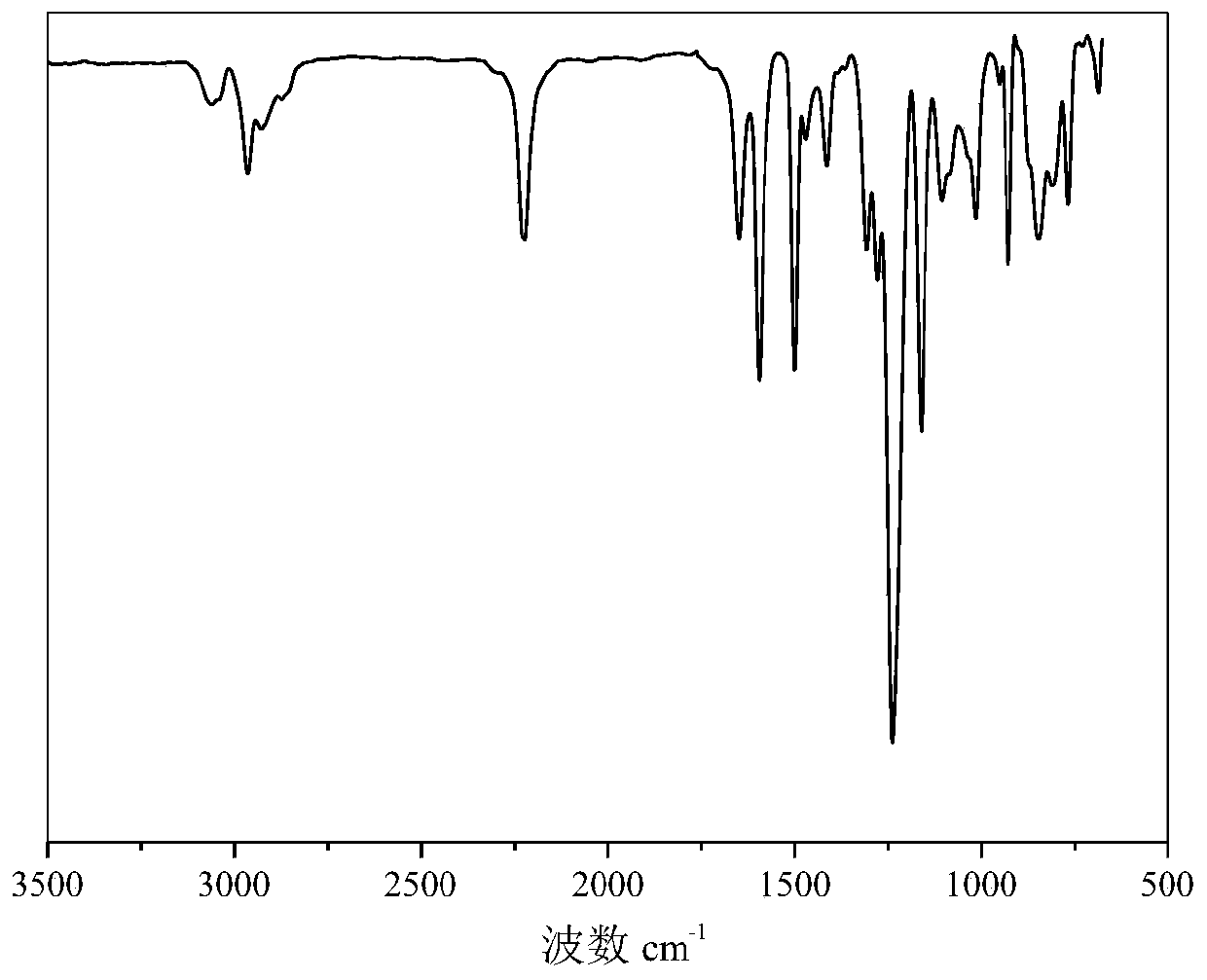

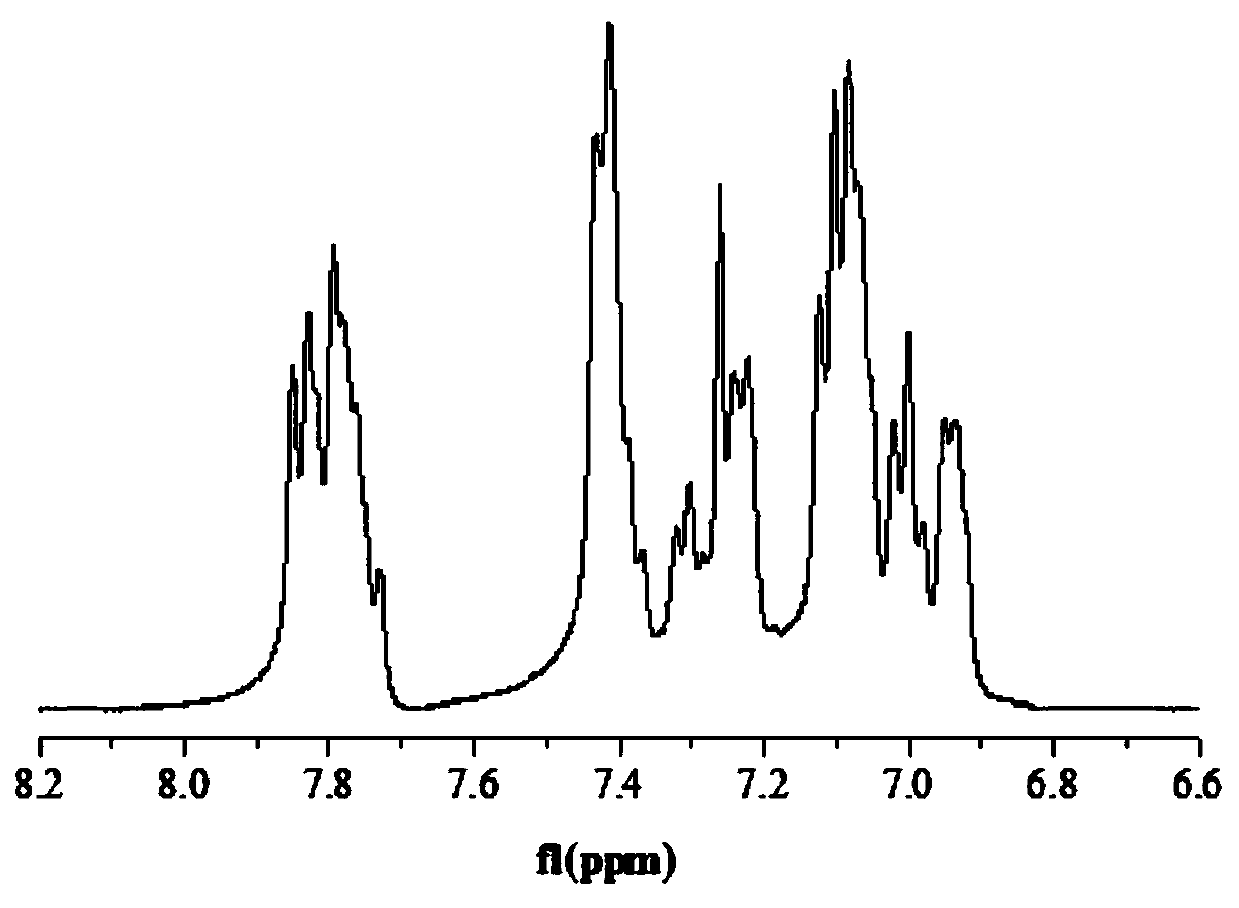

[0026] Synthesis of polyaryl ether ketone cable material resin Synthesis: Add 12.25g (5mmol) perfluorocyclobutyl aryl ether phenol polymer, 5.04g (15mmol) hexafluorobisphenol A, 1.39g (10mmol) 2 , 5-difluorobenzonitrile, 2.18g (10mmol) 4,4'-difluorobenzophenone, toluene 100mL, DMAc120mL, 5.53g (40mmol) potassium carbonate, in 1mL / s N 2 Flow down at 140°C for 3 hours, then raise the temperature to 170°C for 20 hours, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. Soak the filtered precipitate with deionized water, change the water every 3 hours, repeat 7 times, filter, and then filter, place the precipitate in a freeze drying oven for 10 hours to obtain a polyaryletherketone cable material resin sample Analysis by GPC: Mn=46200, PDI=2.34, yield 96%. Its synthetic route:

[0027]

Embodiment 2

[0029] Synthesis of polyaryletherketone cable material resin: 24.50g (10mmol) perfluorocyclobutyl aryl ether phenol polymer, 3.36g (10mmol) hexafluorobisphenol A, 1.39g (10mmol) 2,5 -Difluorobenzonitrile, 2.18g (10mmol) 4,4'-difluorobenzophenone, toluene 100mL, DMAc120mL, 5.53g (40mmol) potassium carbonate, in 1mL / s N 2 Flow down at 140°C for 3 hours, then raise the temperature to 170°C for 20 hours, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. Soak the filtered precipitate with deionized water, change the water every 3 hours, repeat 7 times and then filter, place the precipitate in a freeze drying oven for 10 hours to obtain a polyaryletherketone cable material resin sample and analyze it by GPC : Mn=47200, PDI=2.64, the yield is 98%, and the result of DSC research shows that the glass transition temperature of the polyaryletherketone sample prepared in this embodiment is 185°C, and the result of thermogravimetric a...

Embodiment 3

[0031] Synthesis of polyaryletherketone cable material resin: 24.50g (10mmol) perfluorocyclobutyl aryl ether phenol polymer, 3.36g (10mmol) hexafluorobisphenol A, 0.82g (5mmol) 2,5 -Difluoroterephthalonitrile, 3.27g (15mmol) 4,4'-difluorobenzophenone, toluene 100mL, DMAc120mL, 5.53g (40mmol) potassium carbonate, in 1mL / s of N 2 Flow down at 140°C for 3 hours, then raise the temperature to 170°C for 20 hours, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. Soak the filtered precipitate with deionized water, change the water every 3 hours, repeat 7 times and then filter, place the precipitate in a freeze drying oven for 10 hours to obtain a polyaryletherketone cable material resin sample and analyze it by GPC : Mn=56580, PDI=2.75, yield 94.2%. Its synthetic route:

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com