Phthalonitrile-terminated polyaryletherketone resin and preparation method thereof

A technology of phthalonitrile and polyaryletherketone, applied in the field of phthalonitrile-terminated polyaryletherketone resin and its preparation, polyaryletherketone resin and its preparation field, can solve the problem of glass transition temperature Sufficiently high, increasing difficulty in processing, low glass transition temperature, etc., to achieve the effect of increasing solubility, improving glass transition temperature and mechanical strength, and lowering melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

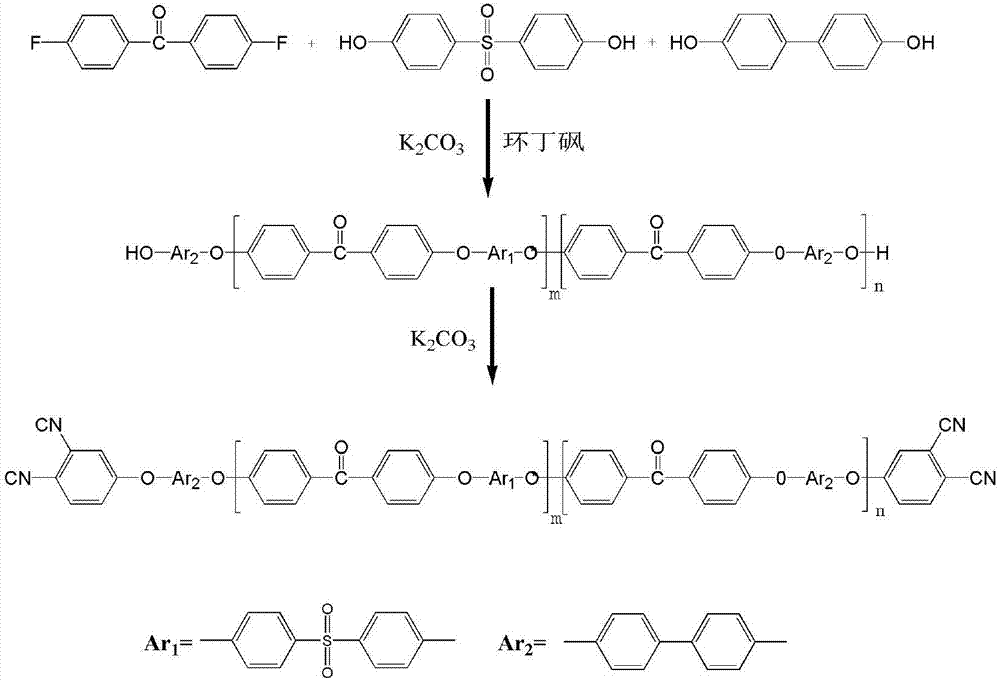

[0043] The preparation method of the phthalonitrile-terminated polyaryl ether ketone resin of the present invention includes the following steps:

[0044] (1) Synthesis of hydroxyl terminated polyaryl ether ketone

[0045] a1. Mix sulfolane and dehydrating agent with a molar ratio of 5-6:1 to 1.29, pass in inert gas protection, mix well, and heat to 80-120℃;

[0046] a2. After the sulfolane is dissolved, add the dihydric phenol. After the dihydric phenol monomer is dissolved, add the catalyst. The temperature is raised to 150-180°C and refluxed for 1.5-2.5h, and then the dihalobenzophenone is added. Hydroquinone and bisphenol S;

[0047] a3. After refluxing at 180~220℃ for 1.5~2.5h, the dehydrating agent and the generated water will be released, and the temperature will be raised to 220~280℃ for 2~4h, then the polymerization reaction will be finished, and the volume of the hydroxyl-terminated polyaryletherketone solution will be V 1 ;

[0048] Among them, the solid content of the react...

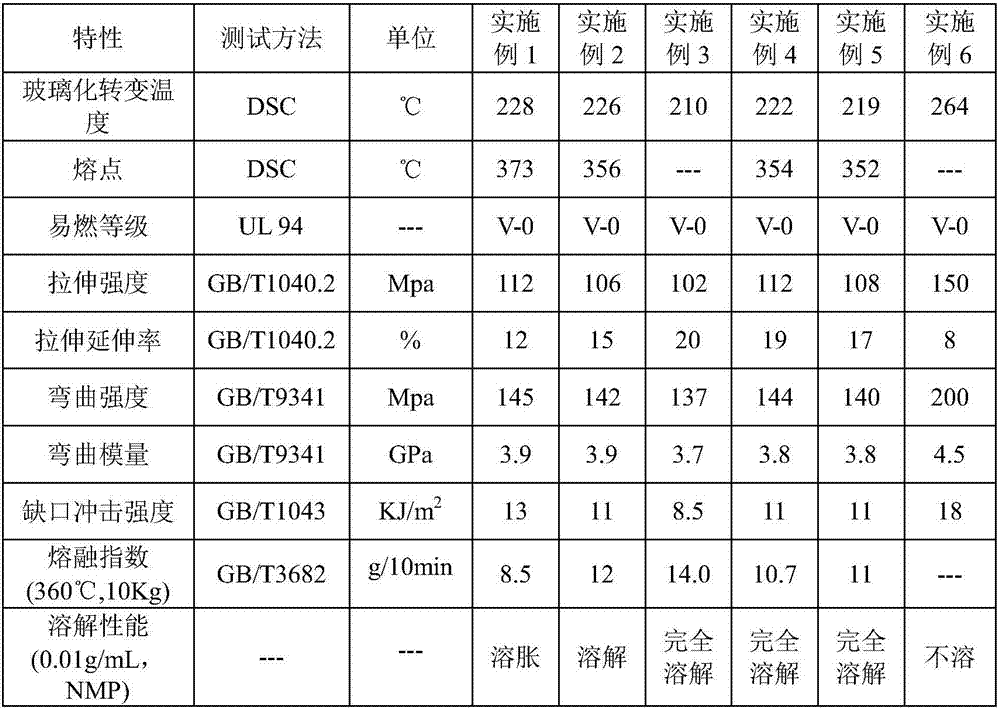

Embodiment 1

[0067] Using 4,4-difluorobenzophenone, biphenol and bisphenol S as raw materials, anhydrous potassium carbonate as a catalyst, and xylene as a dehydrating agent. According to the molar ratio: 4,4-difluorobenzophenone: biphenol: bisphenol S: catalyst=1: 0.75: 0.3: 1.4 to weigh the above raw materials;

[0068] After weighing, add sulfolane and dehydrating agent to the reactor, pass in inert gas protection, turn on the screw-belt screw stirring paddle, stir at 80r / min, heat the reactor to 100℃, and wait until the sulfolane is completely dissolved. Add biphenol and bisphenol S, add the catalyst after the monomer is dissolved, raise the temperature to 160℃ and reflux for 2.5h to make the dihydric phenol form a phenol form, and then add 4,4-difluorobenzophenone to the reaction In the container, the solid content of the reaction system is made 20%; after refluxing reaction at 200°C for 2.5 hours, dehydrating agent and water are released, and then the temperature of the reactor is raise...

Embodiment 2

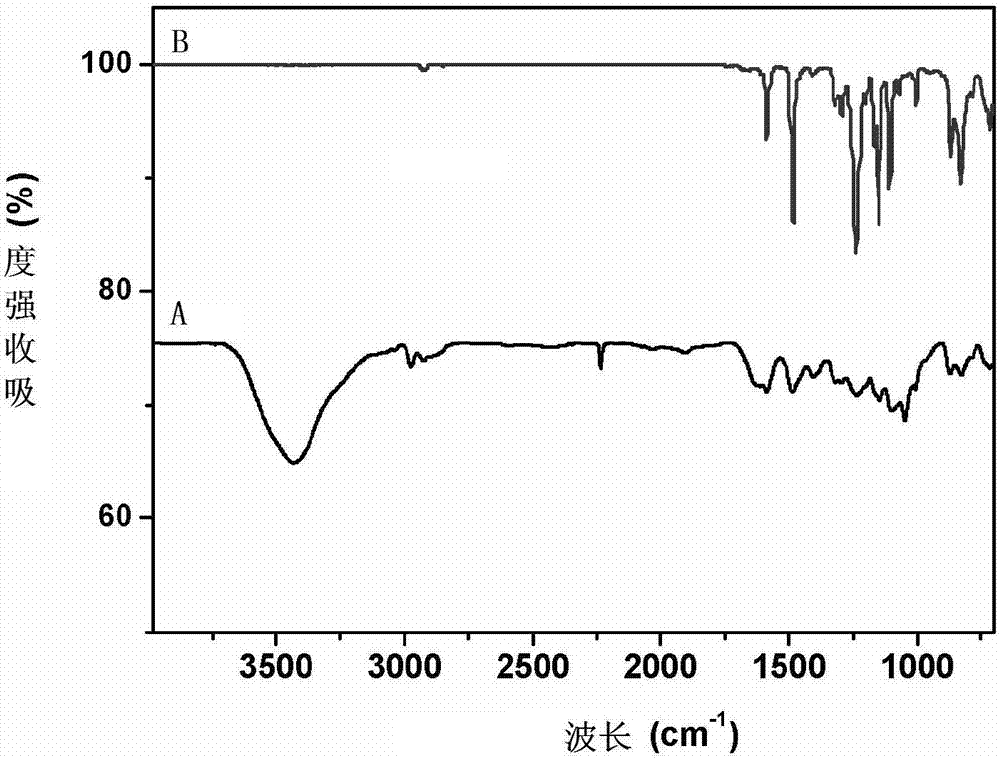

[0071] Refer to Example 1 for the specific method, and the difference from Example 1 is only: according to the molar ratio: 4,4-difluorobenzophenone: dihydroxybenzene: bisphenol S: catalyst=1:0.55:0.5:1.4; The solid content of the reaction system is 25%. The performance parameters of the obtained phthalonitrile-terminated polyaryl ether ketone resin are shown in Table 1, and the infrared spectrum is shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com