Enzyme-containing washing powder for low-temperature washing

A technology of washing powder and low temperature, which is applied in the direction of detergent powder/flake/sheet, detergent compounding agent, detergent composition, etc., and can solve the problems of hot water doping, decontamination ability decline, and washing powder can not fully play the area In the role and other issues, to achieve high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

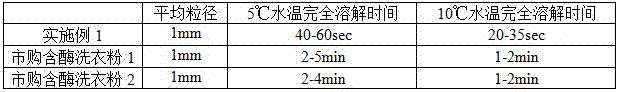

Examples

Embodiment 1

[0038] An enzyme-containing laundry detergent suitable for low-temperature washing, comprising the following components by weight: 32 parts of sodium dodecylbenzenesulfonate, 18 parts of coconut oil fatty acid diethanolamine, 2 parts of embedded compound enzyme, sodium sulfate 40 parts, 1 part of carboxymethyl cellulose, 3 parts of aloe extract, 2 parts of Camellia oleifera cake extract, 2 parts of modified crab shell powder.

[0039] The preparation method of the embedded compound enzyme is as follows: prepare a sodium alginate solution with a concentration of 12wt%, take the compound enzyme (alkaline protease, neutral protease, lipase, cellulase, amylase) and add it to the sodium alginate solution Stir evenly, and then drop the above solution into the calcium chloride solution with a concentration of 3wt% in an amount of 1 mL each time until the cross-linking is fully formed, and then centrifuge and filter to obtain the embedded complex enzyme.

[0040] The preparation metho...

Embodiment 2

[0044] An enzyme-containing laundry detergent suitable for low-temperature washing, comprising the following components by weight: 25 parts of sodium dodecylbenzenesulfonate, 25 parts of coconut oil fatty acid diethanolamine, 1 part of embedded complex enzyme, sodium sulfate 35 parts, 1.5 parts of carboxymethyl cellulose, 2 parts of aloe extract, 1 part of Camellia oleifera cake extract, 3 parts of modified crab shell powder, 0.2 parts of whitening agent, 0.3 parts of essence, sepiolite powder (after surfactant Surface modification treatment) 3 parts, chitosan 3 parts.

[0045] The preparation method of the embedded compound enzyme is as follows: prepare a sodium alginate solution with a concentration of 10%, take the compound enzyme (alkaline protease, lipase, amylase) and add it to the sodium alginate solution and stir evenly, then mix the above solution with Add dropwise 0.5 mL each time into a calcium chloride solution with a concentration of 1% until fully cross-linked an...

Embodiment 3

[0049] An enzyme-containing laundry detergent suitable for low-temperature washing, comprising the following components by weight: 30 parts of sodium dodecylbenzenesulfonate, 15 parts of coconut oil fatty acid diethanolamine, 3 parts of embedded compound enzyme, sodium sulfate 45 parts, 0.5 parts of carboxymethyl cellulose, 2 parts of aloe extract, 1 part of Camellia oleifera cake extract, 1 part of modified crab shell powder, 0.2 parts of whitening agent, 0.3 parts of essence, sepiolite powder (after surfactant Surface modification treatment) 1 part, chitosan 1 part.

[0050] The preparation method of the embedded compound enzyme is as follows: prepare a sodium alginate solution with a concentration of 15%, take the compound enzyme (neutral protease, lipase, amylase) and add it to the sodium alginate solution and stir evenly, then mix the above solution with Add 1.5mL each time into a calcium chloride solution with a concentration of 5wt% dropwise until fully cross-linked and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com