Electro-catalyst of Ni@Au@Pd three-layer core-shell structure with reduced graphene oxide as carrier and preparation method thereof

A technology of electrocatalyst and core-shell structure, applied in the field of electrocatalyst and its preparation, can solve the problems of inability to catalyze the anode process of ethanol oxidation and cathode oxygen reduction reaction at the same time, high cost and poor stability of noble metal catalysts, and achieve excellent catalytic performance, Excellent electrochemical performance and the effect of reducing catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

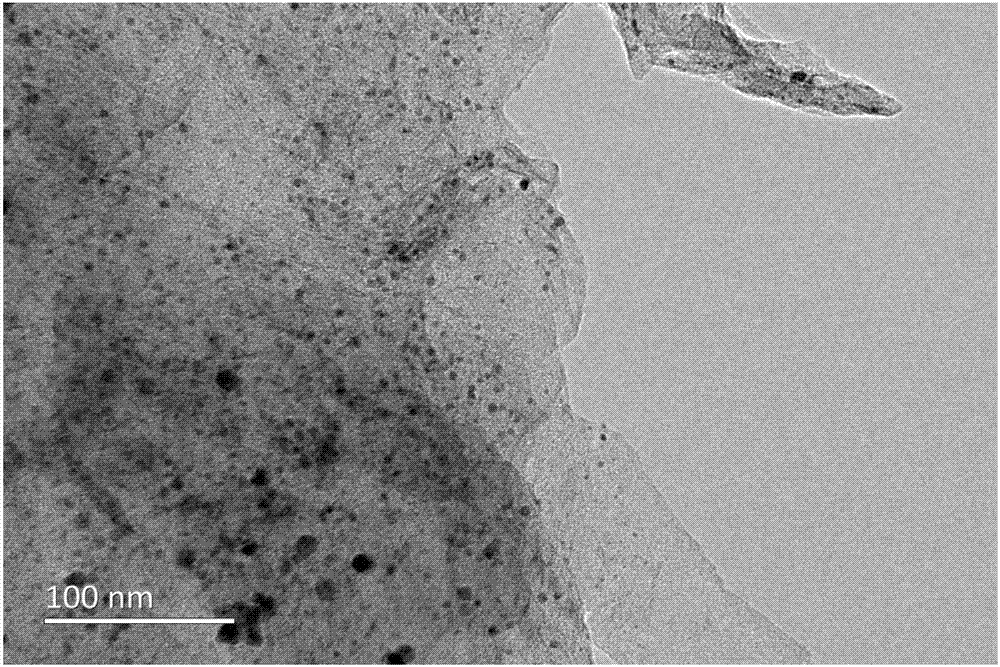

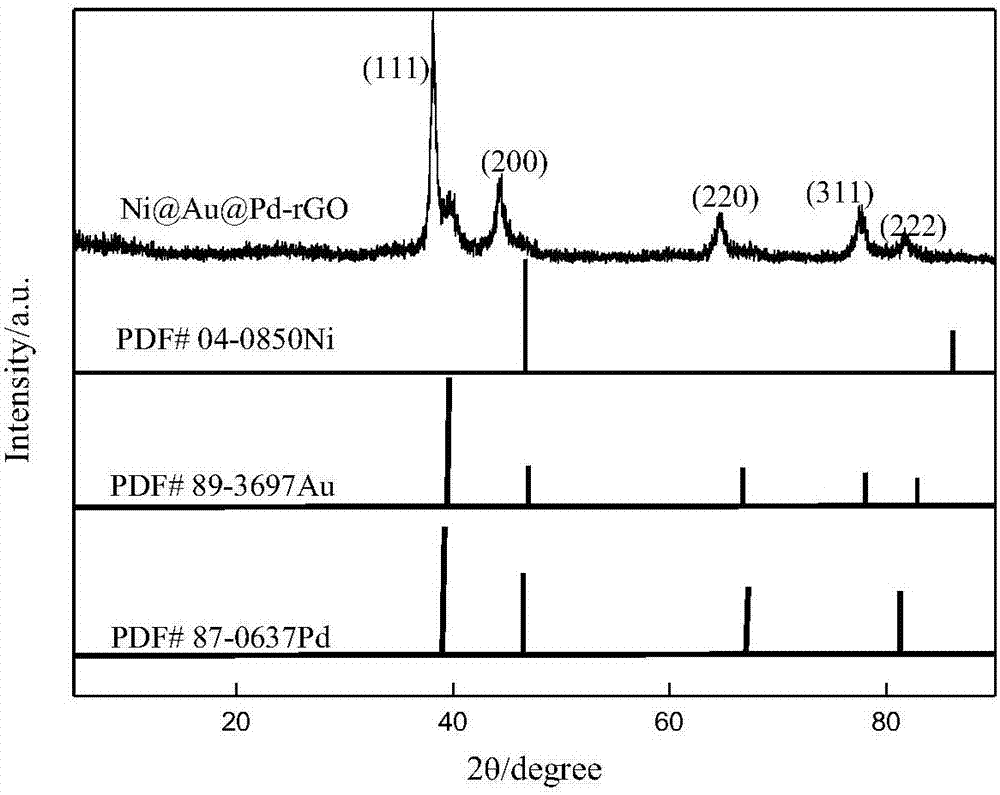

[0030] An electrocatalyst with a three-layer core-shell structure of Ni@Au@Pd based on reduced graphene oxide. Using reduced graphene oxide as a carrier, it is assembled with a thin shell of noble metal Au and Pd on the surface of non-noble metal core Ni to prepare a The average metal nanoparticle size is 7.4nm, with a special three-layer structure of "core-middle layer-shell", which is uniformly dispersed in the multifunctional three-layer core-shell structure electrocatalyst Ni@Au@Pd- rGO.

[0031] The massfraction of Ni is 18% of gained electrocatalyst in the present embodiment; Namely:

[0032] m Ni %=m Ni / (m rGO +m Ni +m Au +m Pd )=14.3 / (50+14.3+7.55+7.2)=18%

[0033] The massfraction of Au is 9.6% of gained electrocatalyst in the present embodiment; Namely:

[0034] m Au %=m Au / (m rGO +m Ni +m Au +m Pd )=7.55 / (50+14.3+7.55+7.2)=9.6%

[0035] The massfraction of Pd is 9.1% of gained electrocatalyst in the present embodiment; Namely:

[0036] m Pd %=m P...

Embodiment 2

[0044] 1) Prepare 500ml of potassium hydroxide solution of 2.0mol / L, prepare 500ml of potassium hydroxide solution of 2.0mol / L and 1.0mol / L of ethanol solution.

[0045] 2) Using 985 μl ethanol as a solvent and 15 μl Nafion solution as a binder, 2 mg of Ni@Au@Pd-rGO catalyst was prepared into a 2 mg / ml dispersion liquid, and ultrasonically dispersed.

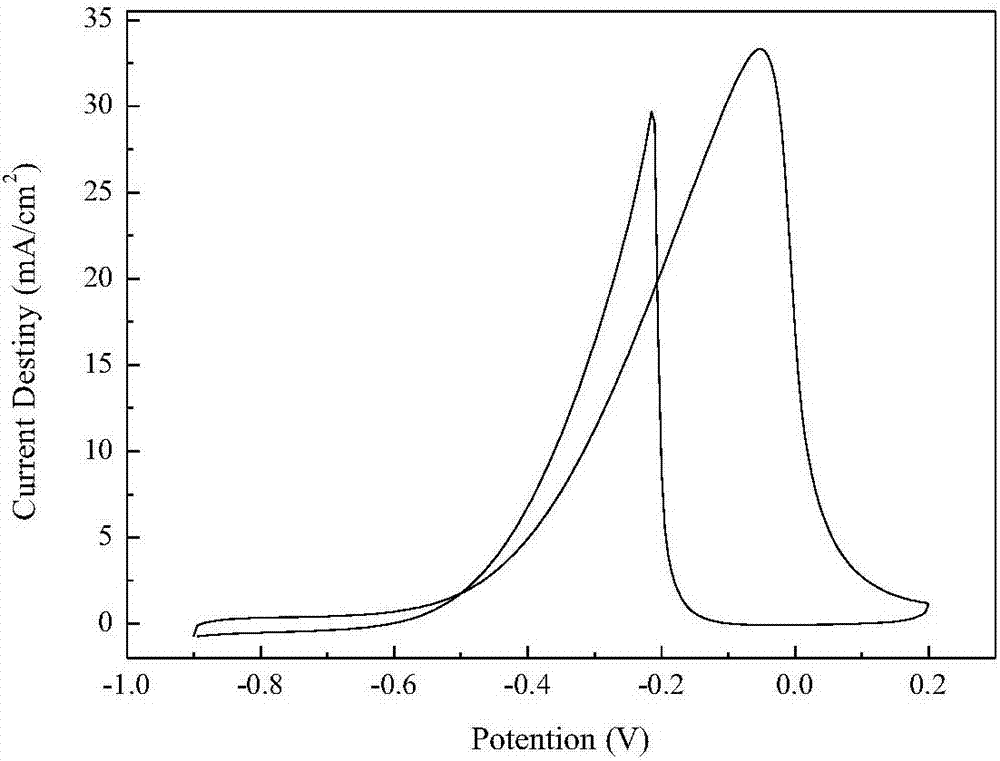

[0046] 3) Take 10 μl of dispersed liquid droplet on the rotating disk electrode (disc area is 0.25cm 2 ), in 2.0mol / L potassium hydroxide solution, N 2 After purging for 30 min, a cyclic voltammetry scan (CV) was performed. After the CV curve is stable, the solution is replaced with 2.0mol / L potassium hydroxide and 1.0mol / L ethanol solution, N 2 After purging for 30 min, the catalytic performance of Ni@Au@Pd-rGO catalyst for ethanol oxidation (EOR) was determined by cyclic linear voltammetry with a scan range of -0.9-0.2V vs. Hg / HgO. from image 3 It can be seen that the nanoparticle catalyst Ni@Au@Pd-rGO with a three-layer ...

Embodiment 3

[0048] 1) Using n-propanol as a solvent, disperse a non-noble metal catalyst with a mass fraction of 3.5% (the ratio of the catalyst to the ionomer is 7:3), and disperse it ultrasonically. The dispersion was evenly sprayed on carbon paper as the cathode of DEFC.

[0049] 2) Using n-propanol as a solvent, disperse the nanoparticle catalyst Ni@Au@Pd-rGO with a core-shell structure, and use 5% polytetrafluoroethylene (PTFE) as a binder (Ni@Au@Pd-rGO and PTFE The mass ratio is 9:1), ultrasonically dispersed. Spray the dispersion evenly on the carbon cloth with a mass fraction of 0.5mg Pd / cm 2 , as the anode of DEFC.

[0050] 3) Assemble the graphite flow field plate, anode carbon cloth, proton exchange membrane, and cathode carbon paper into a DEFC battery, and connect it to a fuel cell test system (Arbin BT2000) to test the performance of the DEFC battery. The anode fuel is 6.0mol / L potassium hydroxide and 3.0mol / L ethanol solution, and the cathode gas is oxygen. Voltage and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com