Graphene-nano-silver composite material, preparation method and application thereof

A composite material, graphene technology, applied in the directions of botanical equipment and methods, applications, textiles and papermaking, etc., can solve the problems of complex production operation, poor antibacterial effect, poor health care effect, etc., achieve good antibacterial and bactericidal effect, improve Microcirculation, simple composition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

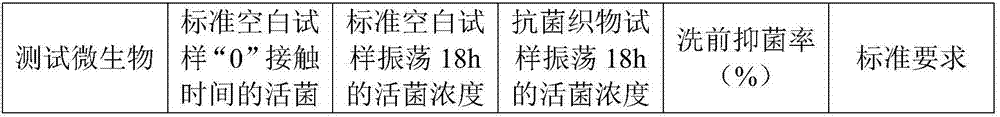

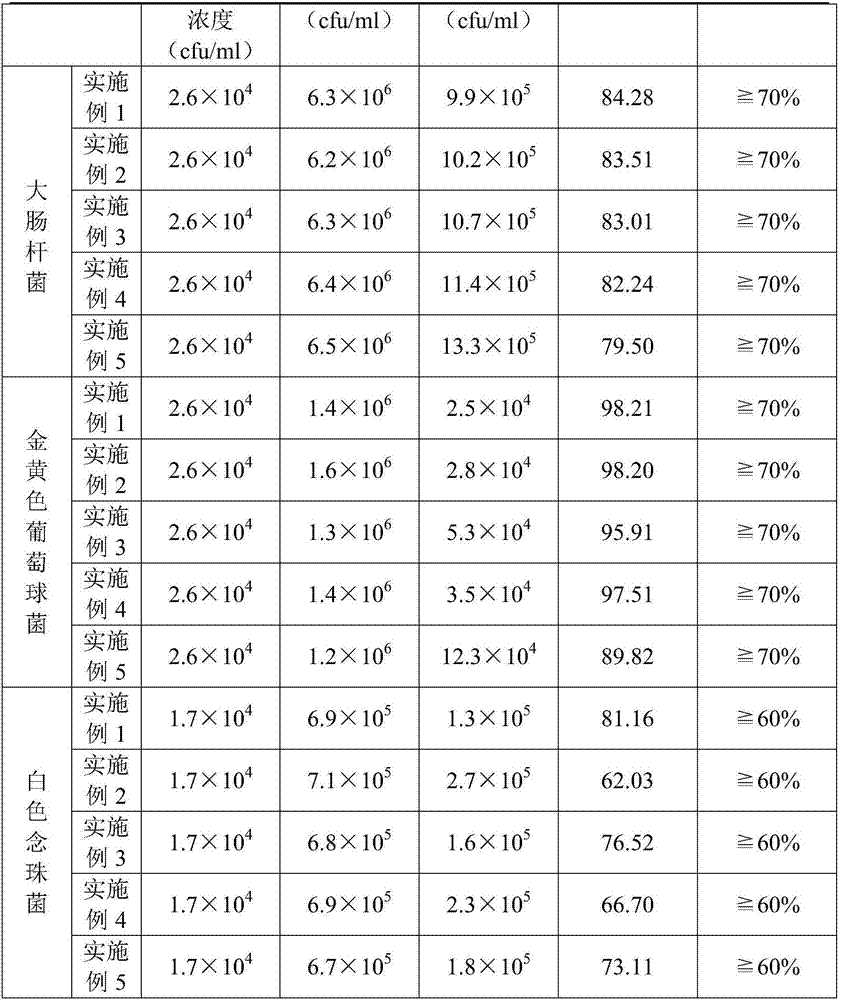

Examples

Embodiment 1

[0043] A kind of blended yarn is prepared according to the following steps:

[0044] 1) Preparation of graphene-nano-silver composite material

[0045] A, prepare graphene mixed powder; Get graphene 35g, graphite carbon 13g and graphite 4.5g, mix evenly, grind, to obtain final product;

[0046] B. Prepare nano-silver antibacterial powder; take 2g of silver nitrate, 91.5g of nano-sized zirconium phosphate and 2g of zinc oxide; configure silver nitrate into silver nitrate solution, then add zirconium phosphate, and add zinc oxide while stirring to obtain the first dispersion liquid; prepare the first dispersion liquid with deionized water to make the second dispersion liquid with a concentration of 5-12%, then stir at constant temperature for 3 hours, wash and filter, dry the filter residue at 120°C, and control the moisture content Below 7.5%, after the dried solid is crushed, it is calcined at 420°C for 5 hours, cooled to room temperature, ground and pulverized to obtain the ...

Embodiment 2

[0055] A kind of blended yarn is prepared according to the following steps:

[0056] 1) Preparation of graphene-nano-silver composite material

[0057] A, prepare graphene mixed powder; Get graphene 65g, graphite carbon 25g and graphite 10g, mix evenly, grind, to obtain final product;

[0058] B. Prepare nano-silver antibacterial powder; take 5g of silver nitrate, 90g of nano-sized zirconium phosphate and 5g of zinc oxide; configure silver nitrate into silver nitrate solution, then add zirconium phosphate, and add zinc oxide while stirring to obtain the first dispersion ; Prepare the prepared first dispersion with deionized water to form a second dispersion with a concentration of 5-12%, then stir at a constant temperature for 3.5 hours, wash and filter, dry the filter residue at 125°C, and control the moisture content Below 7.5%, after the dried solid is crushed, it is calcined at 425°C for 6 hours, cooled to room temperature, ground and pulverized to obtain the product;

...

Embodiment 3

[0067] A kind of blended yarn is prepared according to the following steps:

[0068] 1) Preparation of graphene-nano-silver composite material

[0069] A, prepare graphene mixed powder; get graphene 30g, graphite carbon 20g and graphite 2g, mix evenly, grind, to obtain final product;

[0070] B, prepare nano-silver antibacterial powder; get silver nitrate 4.5g, nano-scale zirconium phosphate 94g and zinc oxide 2.5g; silver nitrate is configured into silver nitrate solution, then add zirconium phosphate, add zinc oxide while stirring, obtain the first Dispersion liquid; prepare the first dispersion liquid with deionized water to prepare the second dispersion liquid with a concentration of 5-12%, then stir at constant temperature for 2.5 hours, wash and filter, and dry the filter residue at 110°C, and control The moisture content is below 7.5%, the dried solid is crushed, then calcined at 415°C for 5.5h, cooled to room temperature, ground and pulverized to obtain the product; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com