Magnetic compound diatomite material and preparation method thereof

A technology of composite diatomite and diatomite, which is applied in chemical instruments and methods, hybrid capacitor electrodes, physical/chemical process catalysts, etc., can solve the problems of few high value-added products, single product variety, and low grade, and achieve The effect of uniform and controllable size, consistent shape and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing the magnetic composite diatomite material described in the above technical solution, comprising the following steps:

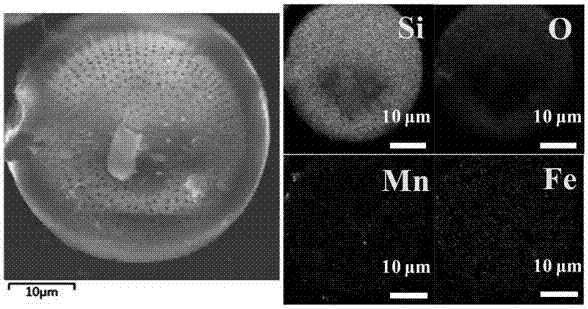

[0050] a) Mix the carrier with an aqueous solution of manganese salt, and perform a hydrothermal reaction to obtain nano-MnO 2 / Diatomite composite material; the carrier is diatomite; the shell size of the diatomite is 10 μm to 50 μm, and the specific surface area is 1m 2 / g~4m 2 / g;

[0051] b) the nano MnO obtained in step a) 2 / diatomite composite material reacts with ferrous salt in a solvent to obtain a solid product;

[0052] c) Calcining the solid product obtained in step b) to obtain a magnetic composite diatomite material.

[0053] In the present invention, firstly, the carrier is mixed with the aqueous solution of manganese salt, and the hydrothermal reaction is carried out to obtain nanometer MnO 2 / Diatomaceous earth composite material. In the present invention, the carrier is ...

Embodiment 1

[0067] (1) Disperse 30 mg of diatomaceous earth in 30 mL of 0.01 M potassium permanganate solution, stir with a magnetic stirrer for 10 min, then conduct a hydrothermal reaction at 140 ° C for 13 h, wash the reacted product with water and ethanol, and then Dry at 60°C to obtain nano-MnO 2 / Diatomaceous earth composite material;

[0068] (2) the above-mentioned nano-MnO 2 / Diatomite composite material is dispersed in FeSO with a dosage ratio of 5mg: 56mL: 8mL 4 / ethylene glycol / water solution, using a magnetic stirrer to stir for 10 minutes, then conduct a hydrothermal reaction at 100°C for 7 hours, wash the reacted solid product with water and ethanol, dry it at 60°C, and put it in a tube furnace Calcined at 350°C for 4 hours and cooled to obtain a magnetic composite diatomite material.

[0069] Example 1 of the present invention obtains the scanning electron microscope picture of magnetic composite diatomite material as Figure 1~2 As shown, among them, figure 1 Obtain ...

Embodiment 2

[0071] (1) Disperse 30 mg of diatomaceous earth in 30 mL of 0.05 M potassium permanganate solution, stir with a magnetic stirrer for 10 min, then conduct a hydrothermal reaction at 150 ° C for 12 h, wash the reacted product with water and ethanol, and then Dry at 60°C to obtain nano-MnO 2 / Diatomaceous earth composite material;

[0072] (2) the above-mentioned nano-MnO 2 / Diatomite composite material is dispersed in FeSO with a dosage ratio of 20mg: 56mL: 8mL 4 / ethylene glycol / water solution, using a magnetic stirrer to stir for 10 minutes, then conduct a hydrothermal reaction at 90°C for 8 hours, wash the reacted solid product with water and ethanol, dry it at 60°C, and put it in a tube furnace Calcined at 350°C for 4 hours and cooled to obtain a magnetic composite diatomite material.

[0073] Example 2 of the present invention obtains the scanning electron microscope picture of magnetic composite diatomite material as Figure 3-4 As shown, among them, image 3 Obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com