Preparation method for high-strength copper alginate aerosol catalyst

A copper alginate, aerosol technology, applied in chemical instruments and methods, physical/chemical process catalysts, catalytic reactions, etc., can solve problems such as low mechanical properties, and achieve good mechanical properties, high conversion rate, and high reactivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

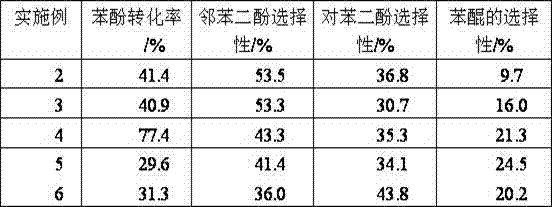

[0035] Take sixteen groups of catalysts for the orthogonal test, weigh 1.0 g (10 mmol) of phenol and 50 mg of catalyst according to the mass ratio of phenol and catalyst of 20:1, and weigh the ratio of the mass g of phenol to the volume mL of the reaction medium as 1 :30 , weigh 30 mL of water; put the weighed phenol, catalyst and water into a three-necked flask, place the three-necked flask in a constant temperature water bath, and stir under magnetic force, when the temperature reaches 70 °C, the phenol and hydrogen peroxide 2 mL (20 mmol) of hydrogen peroxide weighed at a molar ratio of 1:2 was added dropwise to the three-neck flask at a rate of 0.1 mL / min, and the reaction time was started after the addition was completed. The reaction time was 1 h, and the target product. The reaction solution after the reaction in the examples was suction filtered to separate the catalyst and the reaction solution.

[0036] The activity data of the catalyst for phenol hydroxylation are ...

Embodiment 2

[0040] Take the first group of catalysts in the orthogonal test, weigh 1.0 g (10 mmol) of phenol and 20 mg of the catalyst according to the mass ratio of phenol and catalyst of 50:1, and weigh the ratio of the mass of phenol to the volume of the reaction medium as 1:30 g / mL, weigh 30 mL of water; put the weighed phenol, catalyst and water into a three-necked flask, place the three-necked flask in a constant temperature water bath, and stir under magnetic force. When the temperature reaches 70 °C, the phenol and Hydrogen peroxide 3 mL (30 mmol) weighed with a hydrogen peroxide molar ratio of 1:3 was added drop by drop into the three-necked flask at a rate of 0.1 mL / min. target product. The reaction solution after the reaction in the examples was suction filtered to separate the catalyst and the reaction solution.

Embodiment 3

[0042] Take the first group of catalysts in the orthogonal test, weigh 1.0 g (10 mmol) of phenol and 10 mg of catalyst according to the mass ratio of phenol and catalyst of 100:1, and weigh 1:30 g according to the mass ratio of phenol and the volume of the reaction medium / mL, weigh 30 mL of water; put the weighed phenol, catalyst and water into a three-necked flask, place the three-necked flask in a constant temperature water bath, and stir under magnetic force. When the temperature reaches 30 °C, the phenol and hydrogen peroxide 1 mL (20 mmol) of hydrogen peroxide weighed at a molar ratio of 1:1 was added dropwise to the three-neck flask at a rate of 0.1 mL / min, and the reaction time was started after the addition was completed. The reaction time was 2 h, and the target product. The reaction solution after the reaction in the examples was suction filtered to separate the catalyst and the reaction solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com