Chitosan composite dressing and preparation method thereof

A chitosan, consistent technology, applied in the field of chitosan composite dressing and its preparation, can solve problems such as insufficient liquid absorption, and achieve the effects of avoiding whitening and swelling, promoting self-coagulation, and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

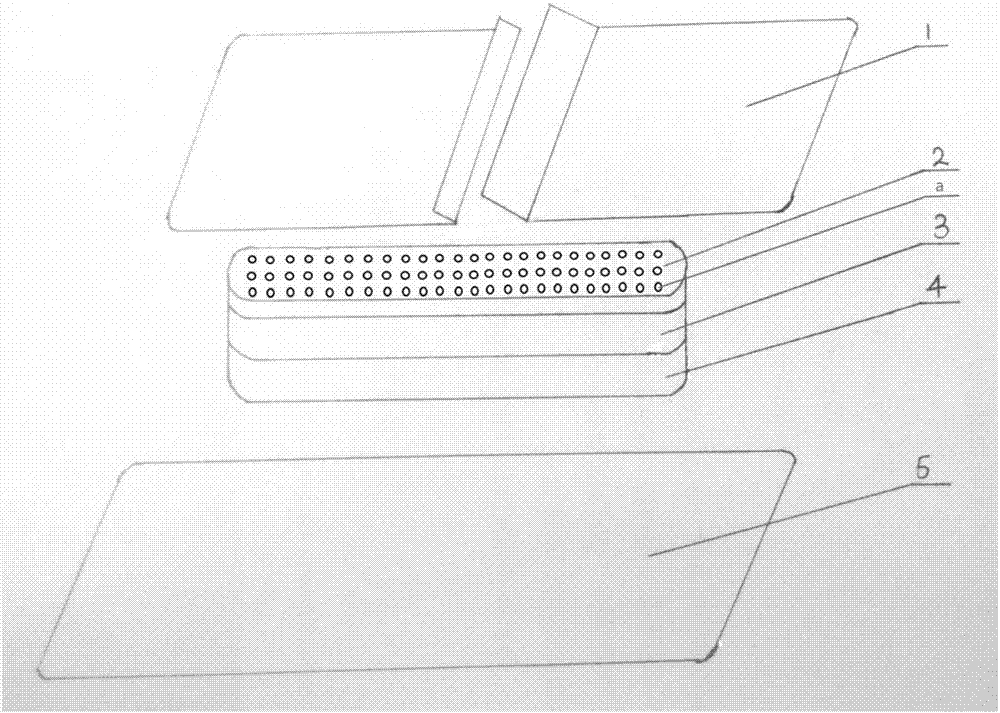

[0033] Such as figure 1 Shown, a kind of chitosan composite dressing comprises chitosan application cushion layer 2, medical absorbent cushion layer 3, waterproof layer 4, medical adhesive tape adhesive layer 5, waterproof layer 4 is covered on the medical adhesive tape adhesive layer 5, and medical absorbent absorbent layer The cushion layer 3 is located between the chitosan cushion layer 2 and the waterproof layer 4. The chitosan cushion layer 2, the medical absorbent cushion layer 3 and the waterproof layer 4 have the same shape and area, and the chitosan cushion layer 2 is covered with a Layer release paper 1, the area is consistent with medical adhesive tape sticking layer 5.

[0034] The area of the chitosan pad layer 2 is smaller than the adhesive layer 5 of medical tape.

[0035] The chitosan pad layer 2 is provided with air vent a, which can increase the air permeability of the dressing, and is oval in shape, and the unique oval design can relieve skin irritation; ...

Embodiment 2

[0044] Step A: Prepare chitosan into a mixed solution with a mass percentage of 3%, the solvent is a mixed solution with a mass percentage of purified water and glycerol of 1:1, stir evenly, and stand for 28 hours to obtain a spinning stock solution ,spare;

[0045] Step B: Under the environment of temperature 25°C and humidity 45%, electrospin the spinning dope, adjust the speed of the micro injection pump to 0.1mL / h, adjust the voltage of the high voltage generator to 18KV, and adjust the speed of the receiving drum The receiving distance is 12cm. By using the power unit to control the horizontal movement and rotation of the receiving drum, the horizontal moving speed of the receiving drum is 0.001mm / s, and the rotating speed of the receiving drum is set to 1000r / s during spinning. sugar spun fibers;

[0046] Step C: soak the chitosan spun fiber in a concentration of 1.0% CaCl 2 Carry out cross-linking in the ethanol solution of cross-linking, after cross-linking 0.5 hour,...

Embodiment 3

[0052] Step A: Prepare chitosan into a mixed solution with a mass percentage of 6%, the solvent is a mixed solution with a mass percentage of purified water and glycerol of 2:1, stir evenly, and stand for 28 hours to obtain a spinning stock solution ,spare;

[0053] Step B: Under the condition of temperature of 25°C and humidity of 45%, electrospinning the spinning stock solution, adjusting the speed of the micro injection pump to 0.1mL / h, adjusting the voltage of the high voltage generator to 15KV, and adjusting the speed of the receiving drum The receiving distance is 15cm. By using the power unit to control the horizontal movement and rotation of the receiving drum, the horizontal moving speed of the receiving drum is 0.002mm / s, and the rotating speed of the receiving drum is set to 2500r / s during spinning. sugar spun fibers;

[0054] Step C: soak the chitosan spun fiber in a concentration of 3.0% CaCl 2 Carry out cross-linking in the ethanol solution of cross-linking, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com