Preparation method of transition metal oxide/sulfide nano composite material

A nano-composite material, transition metal technology, applied in nickel oxide/nickel hydroxide, cobalt oxide/cobalt hydroxide, chemical instruments and methods, etc., can solve the process of difficult control reaction, difficult core-shell hollow material, complex method and other problems, to achieve the effect of uniform size, wide applicability, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 66 mg K 3 [Fe(CN) 6 ] was added to 20 ml deionized water to prepare a solution;

[0028] (2) Weigh 142 mg of NiCl 2 ·6H 2 O, 0.25 g of sodium citrate and 0.3 g of PVP (K29 model) were sequentially added to 30 mL of deionized water and mixed, and ultrasonicated for 5 min;

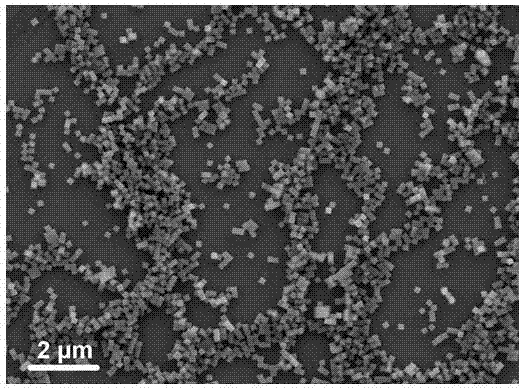

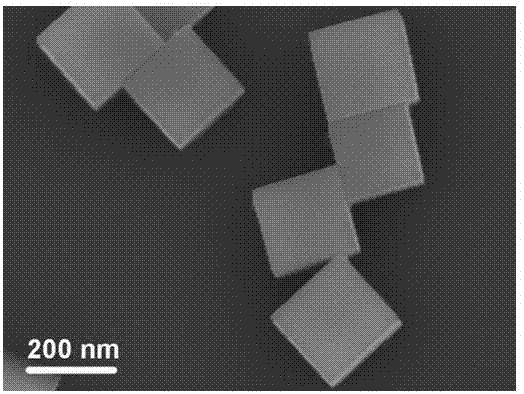

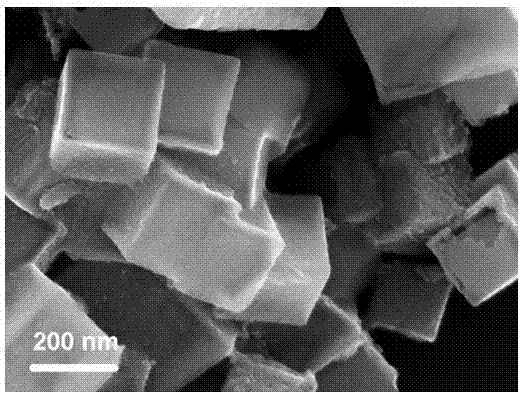

[0029] (3) Add the solution prepared in step (1) dropwise to solution (2), and stir vigorously for 10 min, then cover with plastic wrap and react at 30 °C for 24 h, the solution turns into an orange-yellow dispersion And there is a small amount of precipitation, put it in a centrifuge tube and centrifuge at 10,000 rpm for 5 min, and centrifuge the obtained precipitate with water and absolute ethanol for 4 times, and finally dry it in an oven at 60 °C for 12 h Obtain powder A;

[0030] (4) Weigh 30 mg of powder A obtained in step (3) and add it to a solution prepared by 5 ml of water and 20 ml of absolute ethanol, and then slowly add 0.3 g of Na 2 S·9H 2 O, after reacting for 10 min un...

Embodiment 2

[0033] (1) Weigh 99 mg K 3 [Fe(CN) 6 ] was added to 30 ml deionized water to prepare a solution;

[0034] (2) Weigh 213 mg of CoCl 2 ·6H 2 O, 0.35 g of sodium citrate and 0.65 g of PVP (K29 model) were sequentially added to 45 mL of deionized water and mixed, and ultrasonicated for 15 min;

[0035](3) Add the solution prepared in step (1) dropwise to solution (2), and stir vigorously for 15 min, then cover with plastic wrap and react at 38 °C for 16 h, the solution turns into an orange-yellow dispersion And there is a small amount of precipitation, put it in a centrifuge tube and centrifuge at 11,000 rpm for 8 min, and wash the obtained precipitate with water and absolute ethanol for 5 times, and finally dry it in an oven at 60 °C for 12 h Obtain powder A;

[0036] (4) Weigh 45 mg of powder A obtained in step (3) and add it to a solution prepared by 8 ml of water and 20 ml of absolute ethanol, and then slowly add 0.45 g of Na 2 S·9H 2 O, after reacting for 10 min under ...

Embodiment 3

[0039] (1) Weigh 132 mg K 3 [Fe(CN) 6 ] was added to 40 ml deionized water to prepare a solution;

[0040] (2) Weigh 284 mg of CoCl 2 ·6H 2 O, 0.5 g of sodium citrate and 0.6 g of PVP (K29 model) were sequentially added to 60 mL of deionized water and mixed, and ultrasonicated for 10 min;

[0041] (3) Add the solution prepared in step (1) dropwise to solution (2), and stir vigorously for 10 min, then cover with plastic wrap and react at 30 °C for 24 h, the solution turns into an orange-yellow dispersion And there is a small amount of precipitation, it is placed in a centrifuge tube and centrifuged at 10,000 rpm for 10 min, and the obtained precipitate is washed with water and absolute ethanol for 6 times, and finally dried in an oven at 60 °C for 12 h Obtain powder A;

[0042] (4) Weigh 30 mg of powder A obtained in step (3) and add it to a solution prepared by 5 ml of water and 20 ml of absolute ethanol, and then slowly add 0.6 g of Na 2 S·9H 2 O, after reacting for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com