A preparation method of two-dimensional ordered nano-se lattice on the surface of medical 316l stainless steel

A stainless steel and nanotechnology, applied in the field of 316LSS materials, achieves the effect of convenient operation, good repeatability, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

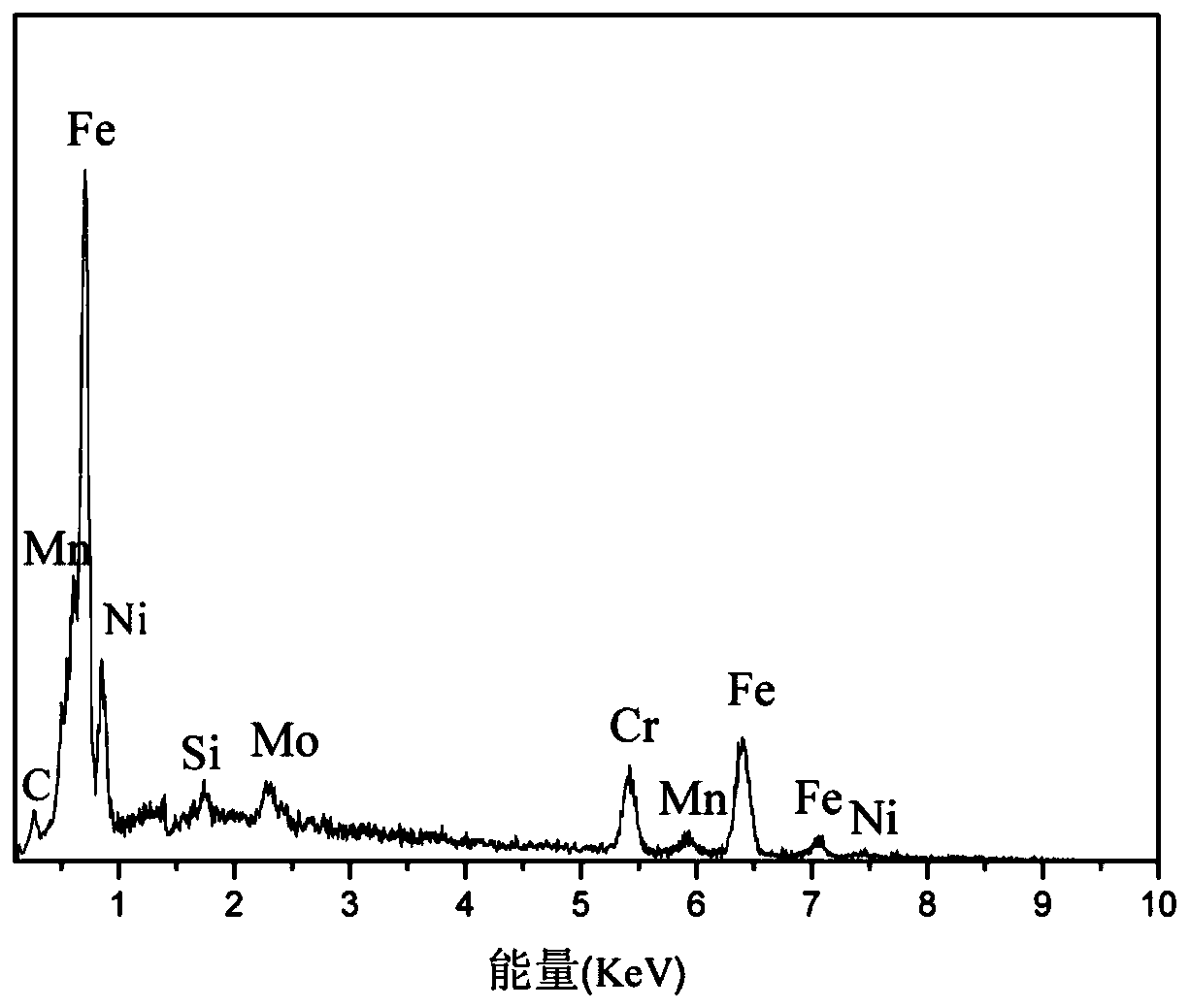

Examples

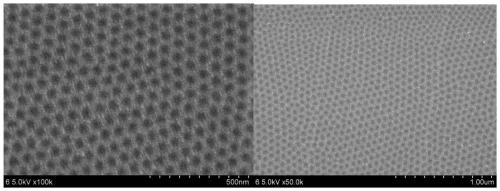

Embodiment 1

[0034] (1) Preparation of nano-pit arrays on the surface of 316LSS: put 316LSS in a mixture of perchloric acid and ethylene glycol (V:V=1:15), the temperature of the system solution is 0°C, anodize at 40V for 10 minutes, and the diameter of the pits is 50nm, the pit depth is 5nm, and the pit density is 1.5×10 10 (pcs / cm 2 ).

[0035] (2) Preparation of Se solution: Add 0.1 g of sodium selenite into 10 mL of deionized water at a temperature of 3° C. and stir evenly; add 0.2 g of ascorbic acid into 20 mL of deionized water at a temperature of 3° C. and stir evenly , and then the sodium selenite solution was added dropwise into the aqueous solution of ascorbic acid while stirring while keeping the temperature at 0° C. for 1 min to obtain the Se solution.

[0036] (3) The Se solution prepared in (2) was quickly dropped into a 316LSS glass vial equipped with a nanopit array, and stood at 5°C for 4h.

[0037] (4) Take out the sample, wash the surface of the material alternately w...

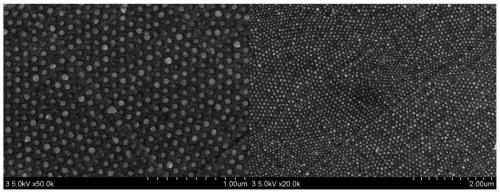

Embodiment 2

[0044] (1) Preparation of nano-pit arrays on the surface of 316LSS: put 316LSS in a mixture of perchloric acid and ethylene glycol (V:V=1:19), the temperature of the system solution is 2°C, anodize at 40V for 11min, the diameter of the pits 70nm, pit depth 7nm, pit density 1.3×10 10 (pcs / cm 2 ).

[0045] (2) Preparation of Se solution: Add 0.1 g of sodium selenite to 10 mL of deionized water at a temperature of 5° C. and stir evenly; add 0.3 g of ascorbic acid to 30 mL of deionized water at a temperature of 5° C. and stir evenly , and then the sodium selenite solution was added dropwise into the aqueous solution of ascorbic acid while stirring while keeping the temperature at 2° C. for 1 min to obtain a Se solution.

[0046] (3) The Se solution prepared in (2) was quickly dropped into a 316LSS glass vial equipped with a nano-pit array, and stood at 5°C for 18h.

[0047] (4) Take out the sample, wash the surface of the material alternately with ethanol and deionized water, a...

Embodiment 3

[0052] (1) Preparation of nano-pit arrays on the surface of 316LSS: put 316LSS in a mixture of perchloric acid and ethylene glycol (V:V=1:25), the temperature of the system solution is 0°C, anodize at 70V for 30s, and the diameter of the pits is 150nm, the pit depth is 5nm, and the pit density is 1.2×10 10 (pcs / cm 2 ).

[0053] (2) Preparation of Se solution: Add 0.1 g of sodium selenite into 10 mL of deionized water at a temperature of 8° C. and stir evenly; add 0.4 g of ascorbic acid into 40 mL of deionized water at a temperature of 8° C. and stir evenly , and then the sodium selenite solution was added dropwise into the aqueous solution of ascorbic acid while stirring while keeping the temperature at 8° C. for 1 min to obtain a Se solution.

[0054] (3) The Se solution prepared in (2) was quickly dropped into a 316LSS glass vial equipped with a nanopit array, and stood at 8°C for 18h.

[0055] (4) Take out the sample, wash the surface of the material alternately with eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com