Magnesium matrix crystal porcelain decorative integrated board

An integrated board and magnesium-based crystal technology, applied in coatings, layered products, construction, etc., can solve the problems that the waterproof performance index cannot achieve the expected effect, fire resistance and water resistance cannot achieve the expected effect, and achieve decorative Variety, low cost and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

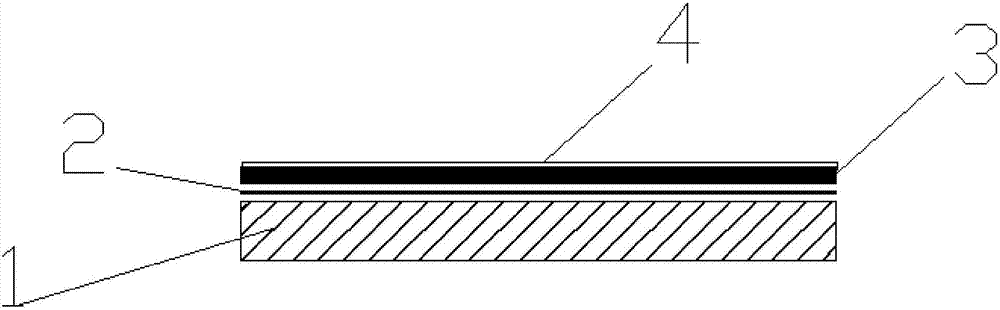

Embodiment 1

[0028] A magnesium-based crystal porcelain decorative integrated board. Magnesium sulfate and magnesium oxide undergo a chemical reaction in an environment with a molar ratio of water, magnesium oxide, and 5:1:8 to form a basic magnesium-based slurry, which is then added to the slab slurry. A mixture of fluffy short glass fibers and wood fiber materials is added to strengthen its toughness. Next, a platinum glass fiber mesh cloth is laid on the slab production line to press out a substrate with a consistent thickness. Next, dry the board, generally using the rapid drying method to dry the board, and finally make the moisture content of the board below 4%. A board with a length of 2400mm, a thickness of 3mm, and a width of 1200mm can be obtained, and then after drying The front side of the plate is scraped and coated with an emulsion mixture formed by modified phenolic resin, melamine, and phosphoric acid as a hot-pressing transition reaction layer, and the impregnated decorativ...

Embodiment 2

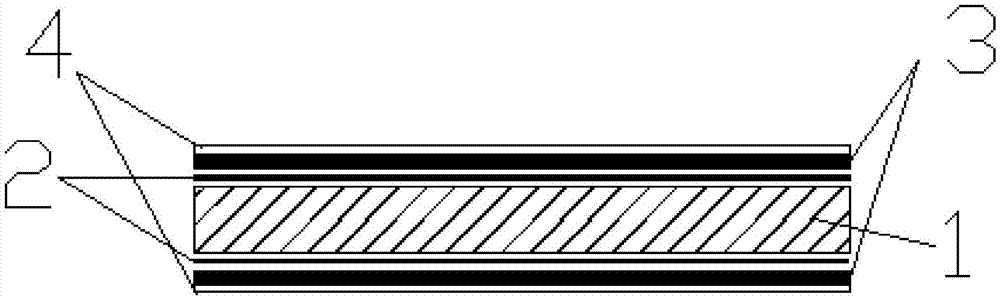

[0030] A magnesium-based crystal porcelain decorative integrated board. Magnesium sulfate and magnesium hydroxide react chemically in an environment where the molar ratio of water, magnesium oxide, and magnesium sulfate is 5:1:8 to form a basic board pulp. Add Filled with velvet short glass fiber and wood fiber, lay 1 to 3 layers of grid-like alkali-free fiber mesh cloth in the slab pressing to strengthen its toughness, and then dry the board, generally using the rapid drying method to dry it. Yes, finally control the moisture content of the board below 3%, and make a board with a length of 3000mm, a thickness of 15mm, and a width of 900mm, and then scrape-coat the front and back sides of the dried board with modified phenolic resin, melamine, The emulsion mixture formed by phosphoric acid is used as the hot-pressing transition interface layer, and then the mixed film of modified melamine and phenolic resin is paved on both sides of the board and hot-pressed with the impregnate...

Embodiment 3

[0032] A magnesium-based crystal porcelain decorative integrated board, which is formed by a chemical reaction in an environment where the molar ratio of magnesium sulfate, magnesium hydroxide powder, magnesium sulfate, and toughening agent is 5:1:8 to form a slab and add it to the slab Made of platinum glass fiber mesh cloth, velvet short polyester fiber and wood fiber powder materials, the slab is pressed on the line to press the slab, and then the slab is dried. After 2 to 7 days of indoor drying, the moisture content of the slab is finally reduced. Reach below 3%, can make length be 3600mm, thickness is 20mm, and width is the board material of 950mm, then sprays the emulsified mixture that modified phenolic resin, melamine, oxalyl formic acid forms on the positive and negative sides of the board after drying as heat Press the transition reaction layer, pave the pre-impregnated decorative surface layer paper and impregnated wear-resistant film on both sides of the board, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com