Fumigation method used for preventing and curing grain pests and mildew

A technology for insect mold and food, which is applied in the field of fumigation to prevent and control food insect mold, and can solve problems such as toxicity, damage to the central nervous system, and strong irritating gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: the preparation of fumigant

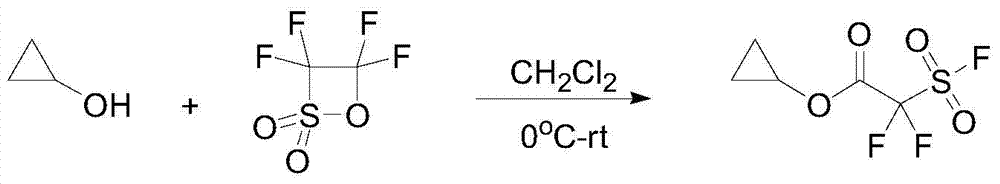

[0052] 1. Preparation of fumigant 15 (2,2-difluoro-2-(sulfonyl fluoride) cyclopropyl acetate):

[0053]

[0054] Take cyclopropanol (58mg) and add dichloromethane (10mL), dropwise add perfluorosulfonate (1mL) under cooling in an ice-water bath. Extracted with methyl chloride (100mL×2), washed with water (10mL×2), washed with saturated brine (10mL×2), dried over anhydrous sodium sulfate, and evaporated to remove the solvent under pressure to obtain the crude fumigant 15 (2,2-difluoro- 2-(sulfonyl fluoride) cyclopropyl acetate), molar yield 90%; 1 HNMR (CDCl 3 )δ(ppm)2.70(m,1H),0.60(m,2H),0.35(m,2H).LR-ESI:[M+H] + 218.99.

[0055] 2. Preparation of fumigants 16, 17, 18, 19, 20, 21, 22, 23:

[0056] With reference to the preparation method of fumigant 15 in 1, cyclobutanol, cyclopentyl alcohol, menthol, isopulegol, dihydrocarveol, carveol, citronellol, citric alcohol and perfluorosulfonate Reaction, so that the correspon...

Embodiment 2

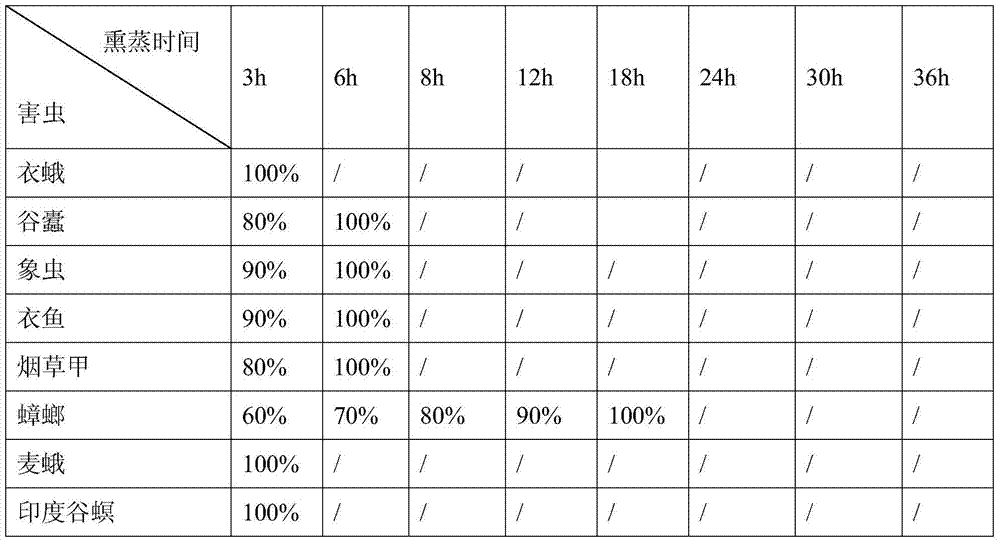

[0067] Embodiment 2: grain fumigation experiment

[0068] Grain varieties: corn, rice, wheat, soybeans, soybeans, broad beans, potatoes, sweet potatoes, etc.

[0069] Diseases: Aspergillus, Penicillium, Trichoderma, Cladoderma cereus, Rhizopus, Trichoderma, Staphylococcus aureus, Escherichia coli, Bacillus megaterium, Bacillus subtilis and Pseudomonas fluorescens, etc.

[0070] Fumigant: Fumigant 24 ( CAS number: 677-25-8)

[0071] First place the fumigant directly in the petri dish, then place the grain sample on top of the petri dish (which can be realized by setting a fixed frame), and fumigate at room temperature.

[0072] After sampling and monitoring, it is known that after 24 hours of fumigation, there is no mold growth on the grain samples after the above-mentioned fumigation treatment (it was found by microscope inspection), and there is no fumigant residue on the grain samples after the above-mentioned fumigation treatment. (It is known from the detection and ana...

Embodiment 3

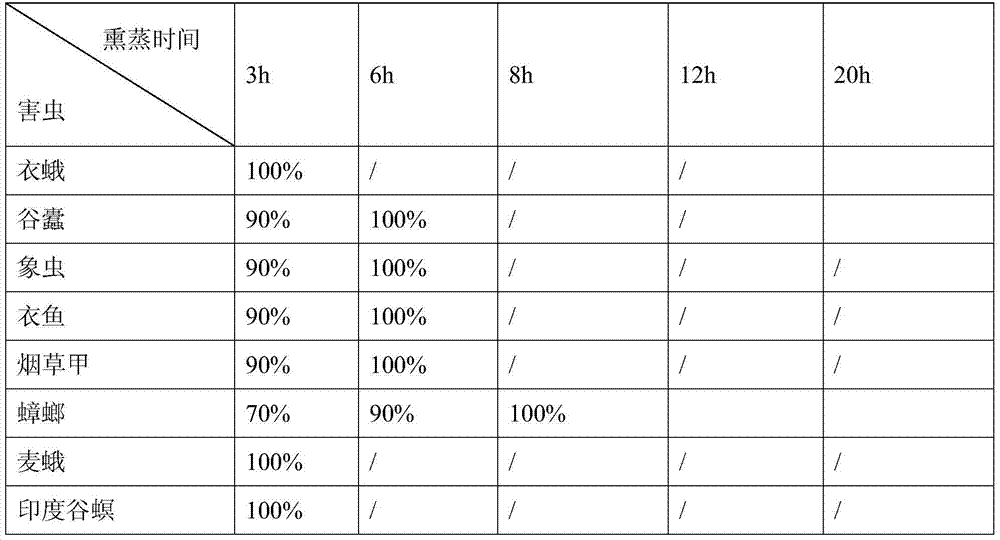

[0076] Embodiment 3: grain fumigation experiment

[0077] Grain varieties: corn, rice, wheat, soybeans, soybeans, broad beans, potatoes, sweet potatoes, etc.

[0078] Diseases: Aspergillus, Penicillium, Trichoderma, Cladoderma cereus, Rhizopus, Trichoderma, Staphylococcus aureus, Escherichia coli, Bacillus megaterium, Bacillus subtilis and Pseudomonas fluorescens, etc.

[0079] Fumigant: Fumigant 25 ( CAS number: 754-03-0)

[0080] First load the fumigant on the silica gel particles, then place the silica gel particles in a bag with a mesh on the surface, then place the bag on the bottom of the glass jar, and place the grain sample on top of the bag (can be obtained by placing the bag in the glass jar) A fixed frame is set in the middle to realize), and the airtight glass cylinder is fumigated at room temperature.

[0081] After sampling and monitoring, it is known that after 36 hours of fumigation, there is no mold growth on the grain samples after the above-mentioned fum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com