Composite nanofiltration membrane based on hydrophilic modified polyolefin microporous substrate and preparation method thereof

A technology of polyolefin microporous membrane and composite nanofiltration membrane, which is applied in the direction of chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of substrate surface morphology damage, poor surface hydrophilicity, membrane structure collapse, etc., and achieve hydrophilic The water layer is thin and uniform, reducing the film resistance of the base film and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A tannic acid-diethylenetriamine system is used as a co-deposition system, wherein the molar ratio of tannic acid-diethylenetriamine is 1:10. The polypropylene microporous substrate was submerged in the co-deposition solution, taken out after 6 hours, washed repeatedly with deionized water, and dried overnight.

[0051] Prepare an aqueous solution of piperazine at a concentration of 2 g / L, and prepare a n-hexane solution of trimesoyl chloride at a concentration of 1 g / L. Immerse the co-deposited substrate in the piperazine aqueous solution, take it out after its surface is fully infiltrated by the aqueous solution, dry it in the air, and then immerse it in the n-hexane solution of trimesoyl chloride, and react at 25 °C 2min. After the reaction, the composite membrane was taken out and washed repeatedly with deionized water to obtain a composite nanofiltration membrane.

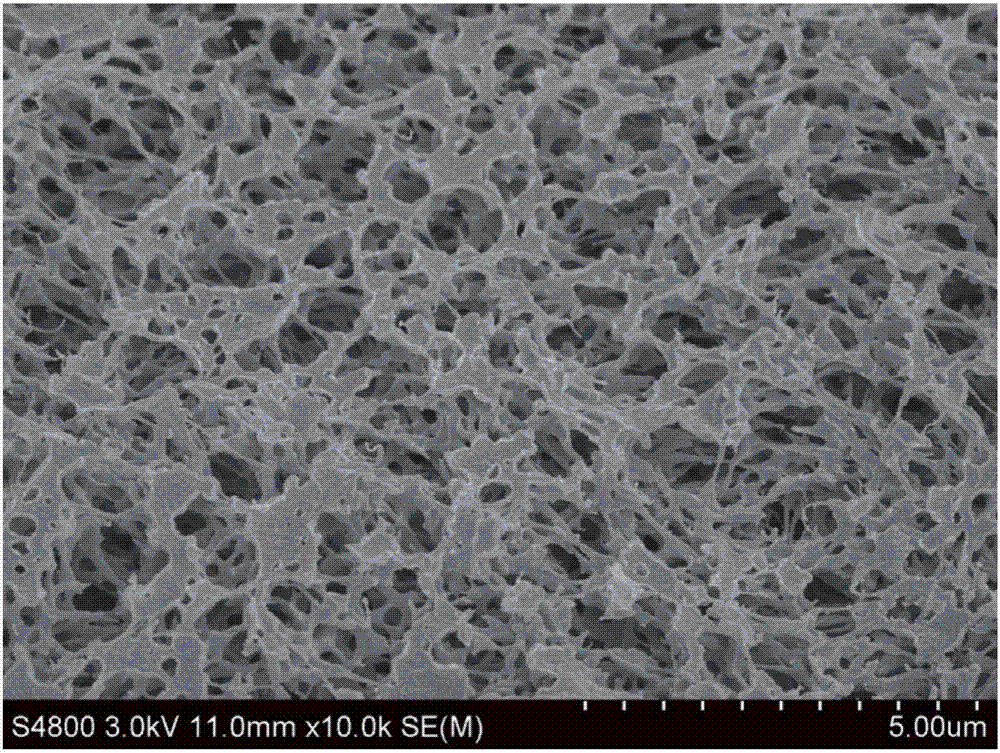

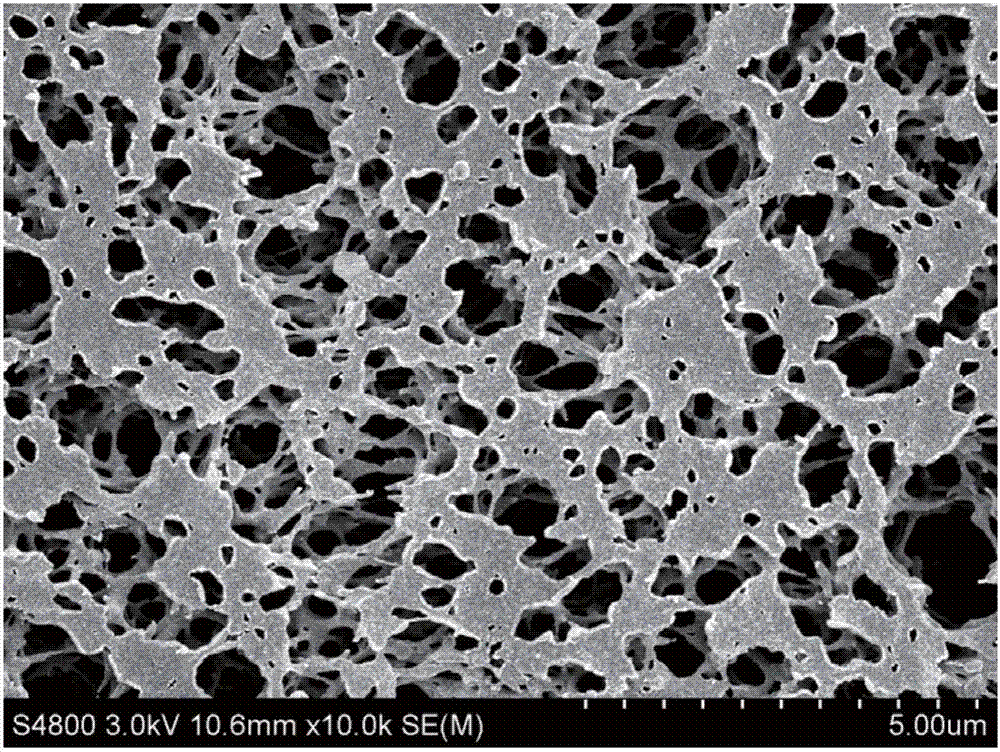

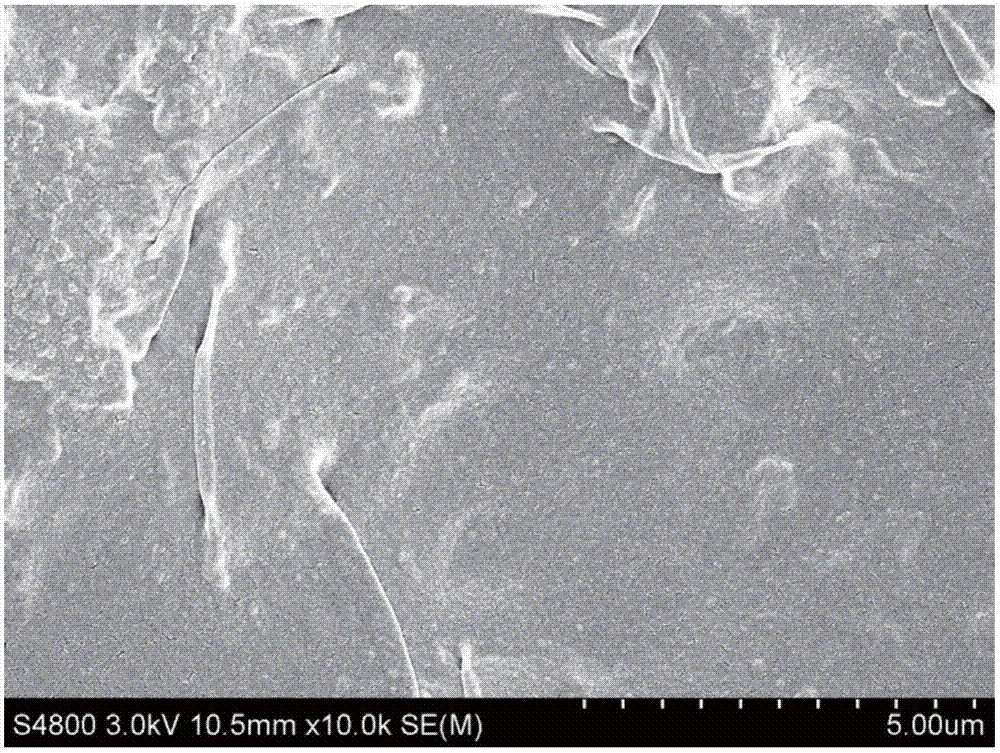

[0052] Electron micrographs of the polypropylene microporous substrate, the hydrophilically modifi...

Embodiment 2~8

[0054] The concentrations of piperazine and trimesoyl chloride were adjusted in the interfacial polymerization reaction, and the rest of the reaction conditions were the same as in Example 1.

Embodiment 9~11

[0061] Post-treatment of composite nanofiltration membranes with organic solvents.

[0062] In Example 9 and Example 10, the composite nanofiltration membrane prepared in Example 1 was respectively immersed in analytically pure ethanol and acetone, taken out after 24 hours, and washed repeatedly with deionized water to obtain post-treated composite nanofiltration membrane.

[0063] Example 11 The composite nanofiltration membrane prepared in Example 1 was immersed in analytically pure dimethylformamide, taken out after 10 minutes, and washed repeatedly with deionized water to obtain a post-treated composite nanofiltration membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com