Microfluidic chip, production method and in-situ catalysis and detection method thereof

A microfluidic chip, in-situ catalysis technology, applied in chemical instruments and methods, measuring devices, instruments, etc., can solve the problems such as the inability to detect the reaction process in situ, the cumbersome separation process of products and catalysts, and the limited quantity of substances, etc. To achieve the effect of increasing the number, large surface area, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

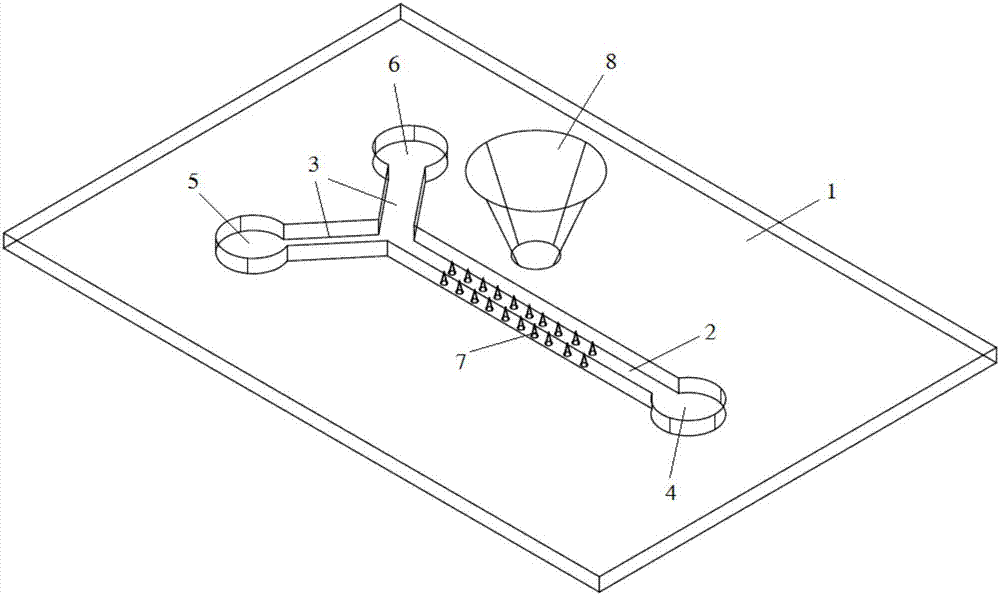

[0032] In this example, the microfluidic chip with in-situ catalysis and detection functions processed periodic spike microstructures inside the silicon-based "Y" channel, and p-nitrophenol and reducing agent sodium borohydride were selected as the model reaction. Under the action of external driving force, the entrances on both sides of the "Y" channel enter the chip respectively, and flow through the Ag-BS composite spike structure, realizing in-situ catalysis, and the Ag-BS composite structure contributes to the formation of surface plasmon resonance elements. , thus realizing the in situ detection of the reaction process by SERS.

[0033] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com