Less-layer MoS2 nano-sheet preparation method

A technology of nanosheets and intercalation agent, which is applied in the field of microwave lithium ion intercalation to prepare few-layer MoS2 nanosheets, can solve the problems of long time and complicated preparation process, and achieves high temperature, simple preparation process and efficient energy utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Few-Layer MoS by Microwave Li-ion Intercalation and Exfoliation 2 The method of nanosheets comprises the following steps: adding 1.14g of lithium hydroxide monohydrate, 0.2g of block molybdenum sulfide and 60mL of ethylene glycol solvent into a beaker, heating in a water bath at 70°C for 25min, then transferring to a domestic microwave oven and heating at 240w 10min, stop for 3min, finish heating for 30min, cool to room temperature with the furnace, centrifuge at a speed of 2000r / min for 7min, then extract the suspension in the upper layer, and then centrifuge at a speed of 10000r / min, wash with acetone during this period, and then wash clean The final black product was dispersed in deionized water and stripped for 45 minutes, filtered with a porous polyvinylidene fluoride filter membrane (pore size of 0.45 μm), and finally the filtered product was placed in a vacuum oven at 70°C for 9 hours to obtain few-layer MoS 2 Nanosheets.

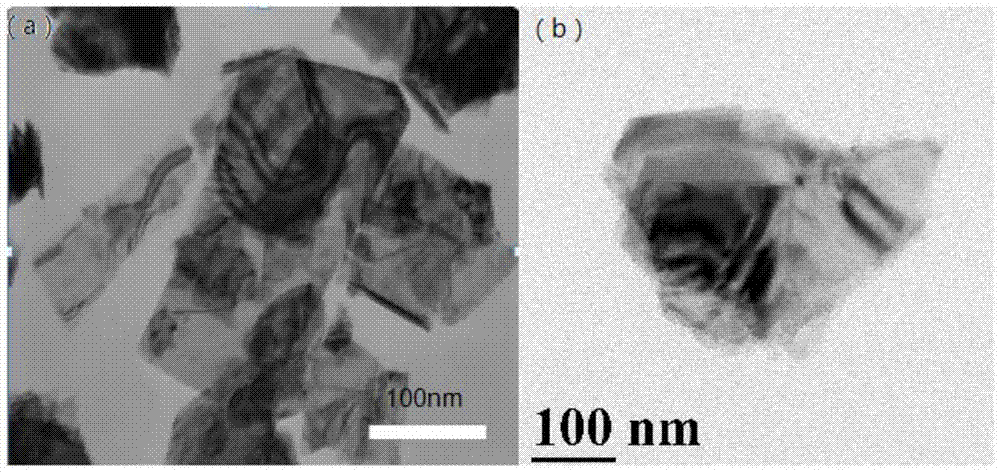

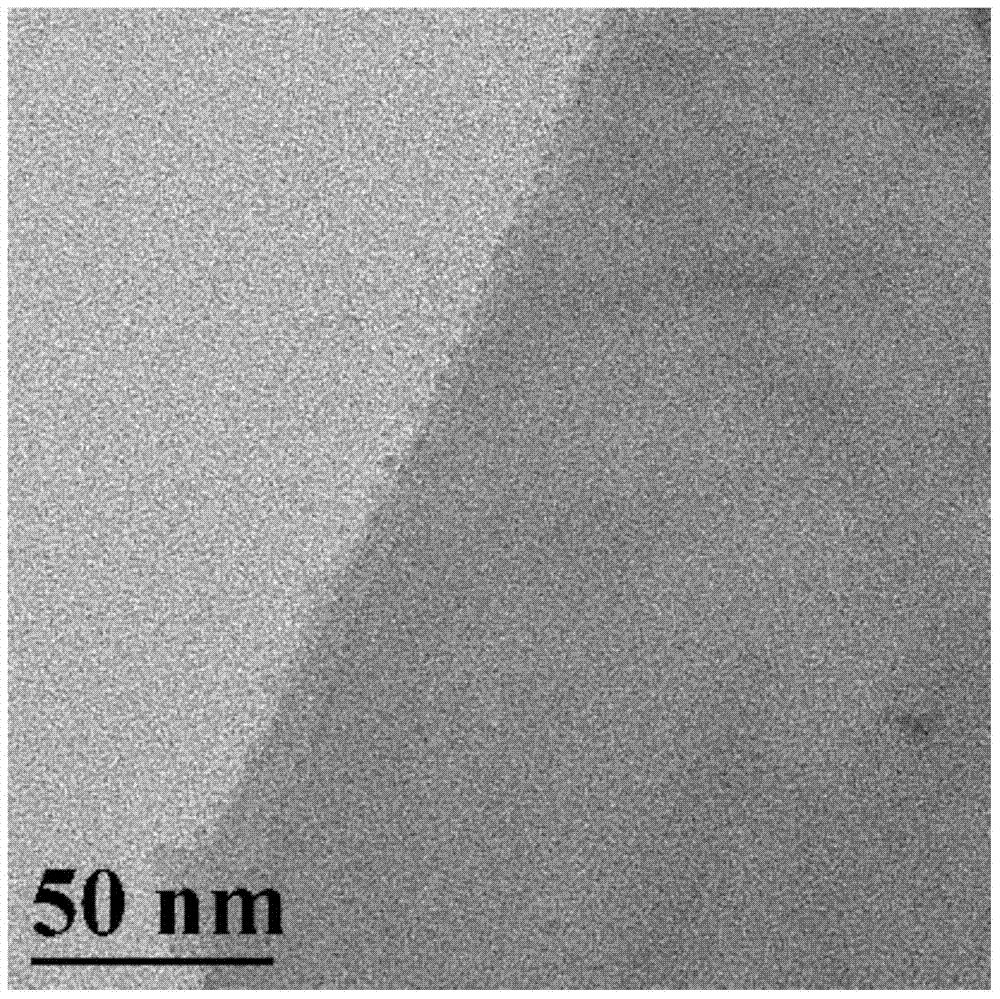

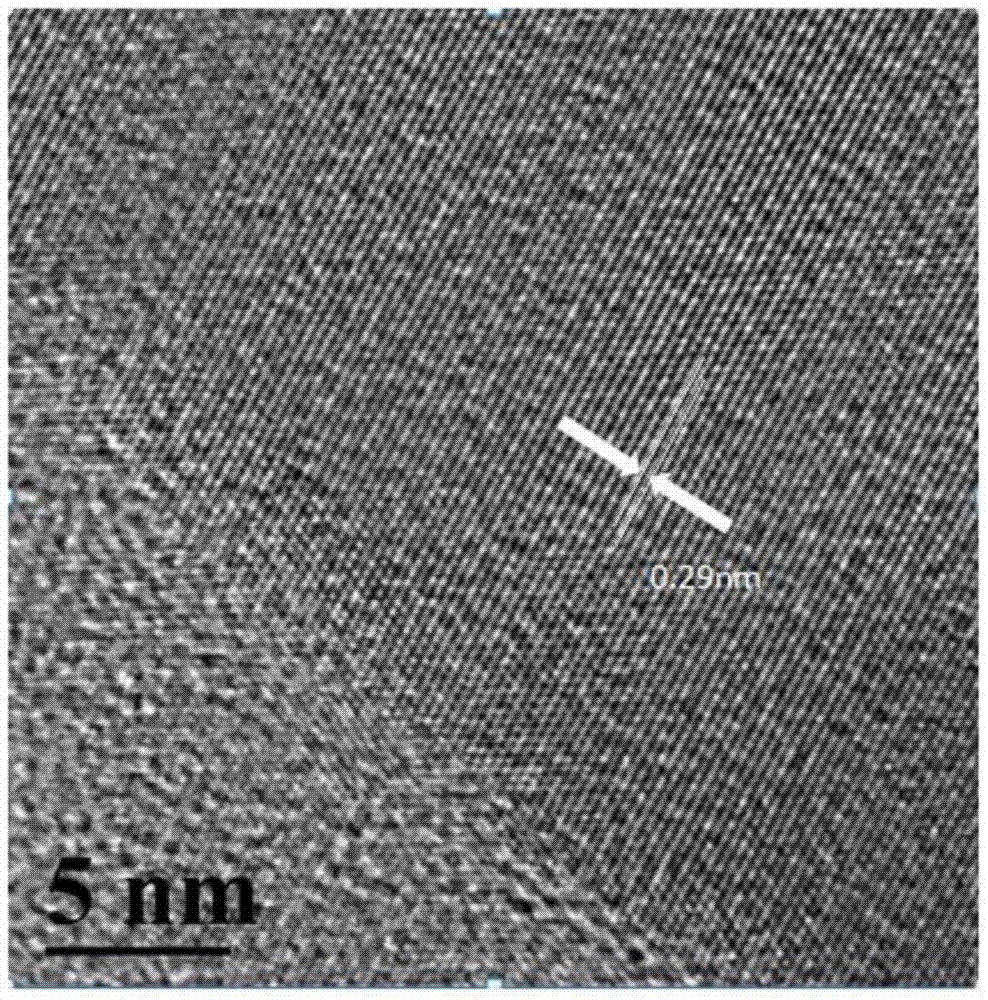

[0038] figure 1For th...

Embodiment 2

[0043] A few-layer MoS 2 The preparation method of the nanosheets comprises the following steps: adding 0.8g lithium hydroxide monohydrate, 0.25g massive molybdenum sulfide and 60mL ethylene glycol solvent into a beaker, heating in a water bath at 70°C for 25min, and mixing the three evenly; Transfer the beaker to a microwave oven for heating. The power of the microwave oven is 200W. The heating program is carried out by heating for 10 minutes and stopping for 3 minutes until the total heating time is 30 minutes. After the microwave heating is completed, it is cooled to room temperature with the furnace; and then the black product is obtained after microwave heating. Centrifuge at a speed of 2000r / min for 6min, then extract the supernatant suspension, and then centrifugally wash with acetone at a speed of 8000r / min. The black product after washing is dispersed in deionized water and ultrasonically stripped for 30min; The polyvinylidene fluoride filter membrane (pore size is 0....

Embodiment 3

[0045] A few-layer MoS 2 The preparation method of the nanosheets comprises the following steps: adding 1.14g of lithium hydroxide monohydrate, 0.3g of massive molybdenum sulfide and 60mL of ethylene glycol solvent into a beaker, heating in a water bath at 60°C for 35min, and mixing the three evenly; then Transfer the beaker to a microwave oven for heating. The power of the microwave oven is 300W. The heating program is carried out by heating for 10 minutes and stopping for 3 minutes until the total heating time is 30 minutes. After the microwave heating is completed, it is cooled to room temperature with the furnace; and the black product is obtained after microwave heating. Centrifuge at a speed of 2500r / min for 10min, then extract the supernatant suspension, and then centrifugally wash it with acetone at a speed of 12000r / min. The black product after washing is dispersed in deionized water and ultrasonically stripped for 60min; The polyvinylidene fluoride filter membrane (p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com