Low-temperature sintered bioglass ceramic material for dental department, and preparation method of bioglass ceramic material

A technology of biological glass and ceramic materials, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of high equipment requirements, high sintering temperature, and difficult processing technology, and achieve simple preparation process and lower sintering temperature , The effect of reducing the difficulty of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

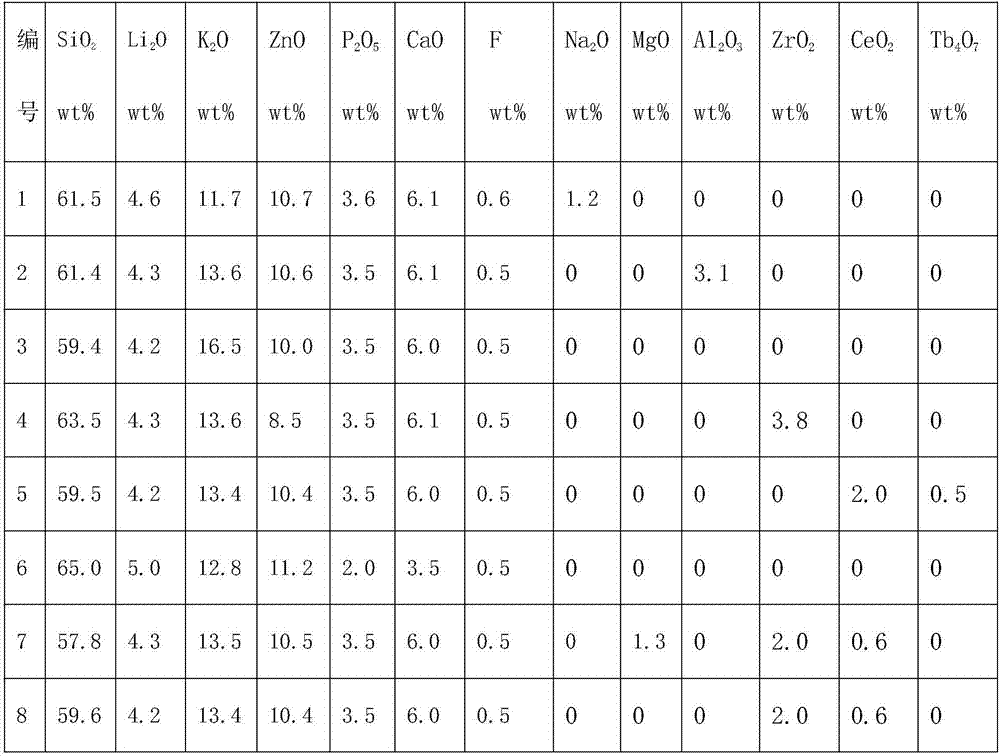

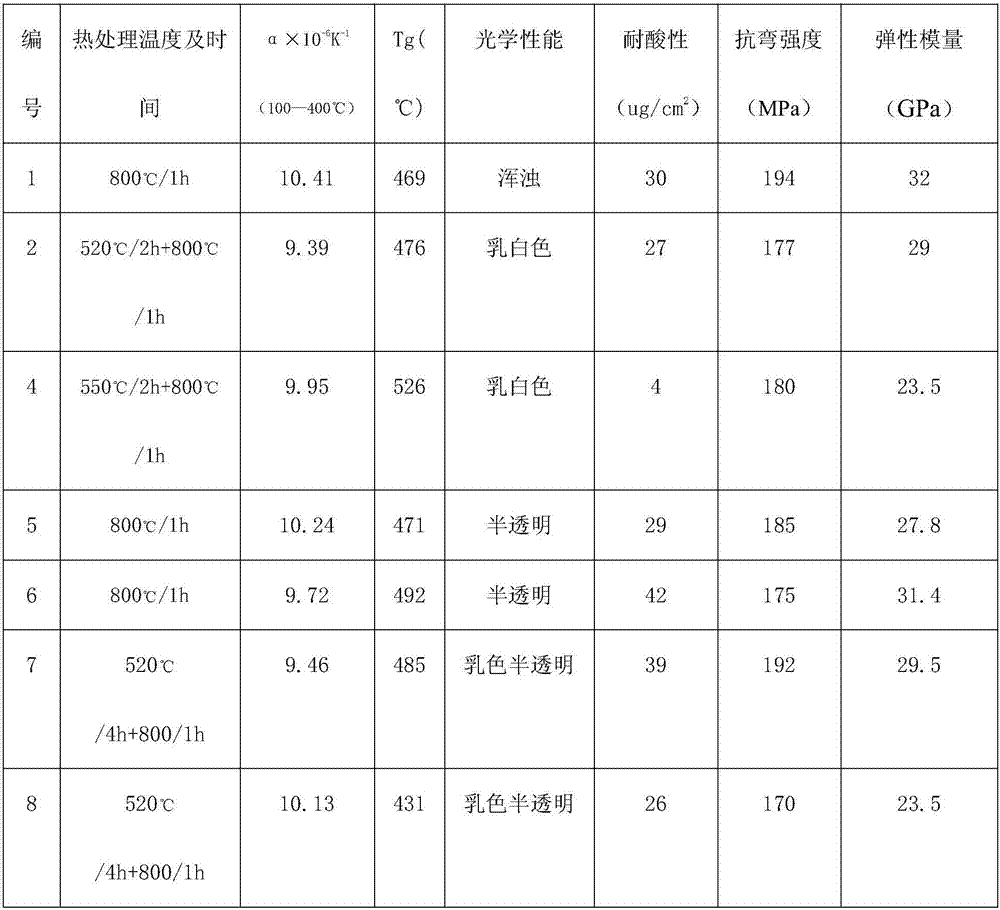

Method used

Image

Examples

Embodiment 1

[0027] Calculate the consumption of raw material according to following weight ratio, 58.5%SiO2, 4.3%Li2O, 12.2%K2O, 10.6%ZnO, 3.5%P2O5, 6.1%CaO, 0.5%F, 0.9%NaO, 1.3%MgO, 0.3%Al2O3, 1.0% ZrO, 0.8% CeO2.

[0028] The raw materials are weighed according to the formula, put into a corundum ball mill jar, and mixed evenly by ball milling for 2 hours, and then dried in a drying oven at a temperature of 80°C; the raw materials are put into a crucible, the heating rate is 15K / min, and the temperature is kept at 1550°C 1.5 hours; after the holding time is up, use the crucible tongs to clamp the crucible, pour the molten glass into water at room temperature to form glass powder; sieve the powder to make the particle size less than 90um, and then press the uniformly mixed powder under pressure 100-200Mpa. Using the isothermal heat treatment system, the green body was put into a vacuum sintering furnace with a heating rate of 50°C / min, kept at 740°C for 1 hour, and cooled with the furna...

Embodiment 2

[0034]Calculate the consumption of raw material according to following weight ratio, 56.5%SiO2, 4.1%Li2O, 12.9%K2O, 10.0%ZnO, 3.3%P2O5, 5.8%CaO, 0.4%F, 3.2%Al2O3, 3.8%ZrO.

[0035] The raw materials are weighed according to the formula, put into a corundum ball mill jar, and ball milled for 2 hours to mix evenly, and then dried in a drying oven at a temperature of 80°C; the raw materials are put into a crucible, the heating rate is 15K / min, and the temperature is kept at 1400°C 1.5h; after the holding time is up, use the crucible tongs to clamp the crucible, pour the molten glass into water at room temperature to form glass powder; sieve the powder to make the particle size less than 90um, and then press the uniformly mixed powder with a pressure of 100~200Mpa. Using a step heat treatment system, put the green body into a vacuum sintering furnace with a heating rate of 40°C / min, keep it at 450°C for 1h, then raise the temperature and keep it at 750°C for 2h, and then cool it w...

Embodiment 3

[0041] The preparation method of the dental biological glass-ceramic material capable of low-temperature sintering comprises the following steps:

[0042] (1) Weigh the raw materials according to the formula requirements;

[0043] (2) Put the raw materials into a corundum ball mill jar, ball mill for 1 hour and mix evenly, and then dry at a temperature of 60° C. in a drying oven;

[0044] (3) Put the raw materials into the crucible, the heating rate is 10K / min, and keep the temperature at 1400°C for 3h;

[0045] (4) Pour the molten glass into water at room temperature to form glass particles;

[0046] (5) Then sieve the particles, and the size of the powder after sieving should be kept between 1 and 450um;

[0047] (6) Press the uniformly mixed powder into a green body with a pressure of 100-200Mpa;

[0048] (7) Using the isothermal heat treatment method, put the green body into a vacuum sintering furnace at a heating rate of 40°C / min, keep it at 740°C for 1 hour, and cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com