Resin composition, adhesive, film type adhesive substrate, adhesive sheet, resin attached copper foil, copper-clad laminate board, wiring board

A resin composition and adhesive technology, applied in the directions of adhesives, adhesive additives, polymer adhesive additives, etc., can solve problems such as insufficient low dielectric properties, and achieve excellent low dielectric properties, good adhesive force, The effect of not easy to glue residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0130] Add commercially available aromatic tetracarboxylic dianhydride (trade name " BTDA-UP ", manufactured by Ebonick Japan Co., Ltd.; 3, 3 ', 4, The content of 4'-benzophenone tetracarboxylic dianhydride is 99.9% or more) 210.0 g, cyclohexanone 1008.0 g, and methylcyclohexane 201.6 g, and the solution was heated to 60°C. Next, 341.7 g of hydrogenated dimerized diamine (trade name "PRIAMINE 1075", manufactured by Croda Japan Co., Ltd.) was added dropwise, and imidization reaction was carried out at 140° C. for 10 hours, thereby obtaining a softening point of A solution of a polyimide resin (A1-1) at about 80° C. and a weight average molecular weight of about 35,000 (30.0% of nonvolatile content). In addition, the molar ratio of acid component / amine component was 1.03.

manufacture example 2

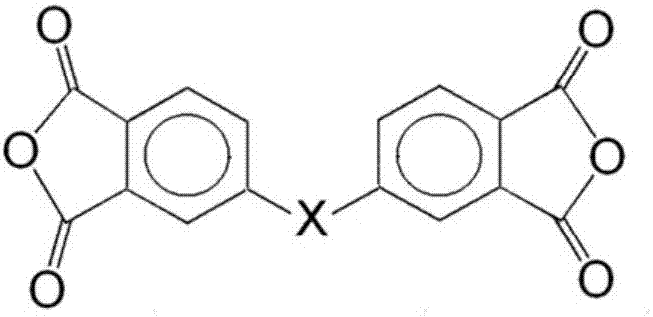

[0132] In the same reaction vessel as in Production Example 1, commercially available aromatic tetracarboxylic dianhydride (trade name "BisDA2000", manufactured by SABIC Japan Contract Co., Ltd.; 4,4'-[propane-2,2-diylbis( The content of 1,4-phenyleneoxy)] diphthalic dianhydride is 99.5% or more), 60.0 g of cyclohexanone 165.0 g, and 27.5 g of methylcyclohexane, and the solution was heated to 60°C. Next, 59.3 g of PRIAMINE 1075 was added dropwise, and then imidization was carried out at 140° C. for 10 hours, thereby obtaining a polyimide resin (A1 -2) solution (non-volatile content 31.9%). In addition, the molar ratio of acid component / amine component was 1.05.

Embodiment 1

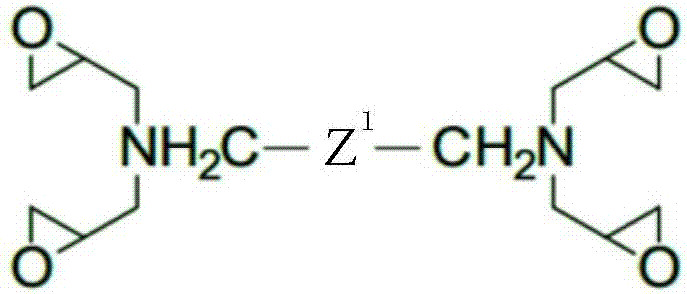

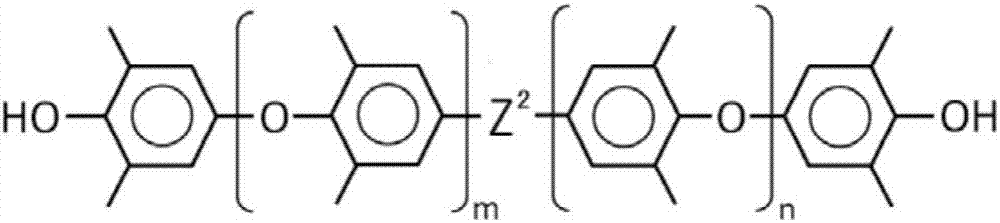

[0150] 100.00 g of a solution of component (A1-1), 1.67 g of tetraglycidyl xylylenediamine (trade name "Tetrad-X", manufactured by Mitsubishi Gas Chemical Co., Ltd.) as component (B) and hydroxyl-containing Polyphenylene ether (trade name "SA90", manufactured by SABIC Corporation) 1.67 g, toluene 7.87 g as (C) component, and a commercially available amino group-containing silane coupling agent as (D) component (trade name "KBM603 ", manufactured by Shin-Etsu Chemical Co., Ltd.; 0.07 g of N-2-(aminoethyl)-3-aminopropyltrimethoxysilane) was mixed to obtain a resin composition (adhesive) with a nonvolatile content of 30.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com