Preparation method of high-sensitivity surface-enhanced Raman scattering substrate

A surface-enhanced Raman, high-sensitivity technology, used in Raman scattering, material excitation analysis, etc., can solve the problems of complex steps, poor concentration control, and low yield, and achieve a simple preparation process, high uniformity, and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

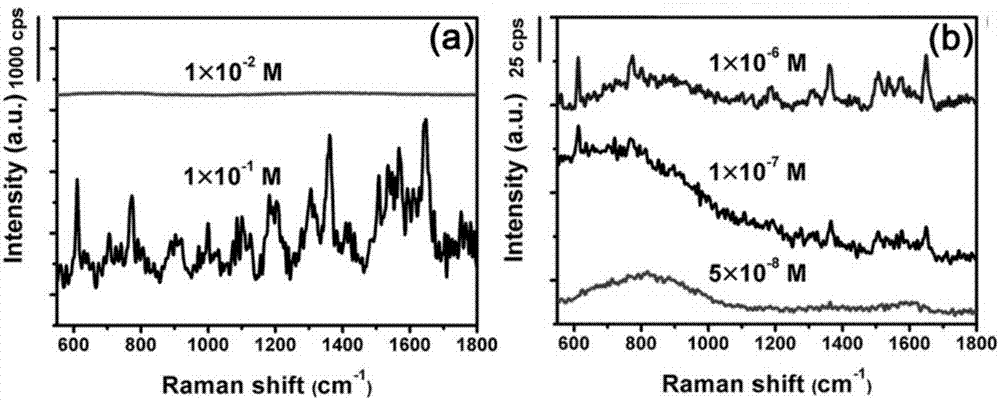

[0031] Firstly, WO was deposited on the quartz substrate by ultra-high vacuum magnetron sputtering (ULVAC ACS-400). 3 Thin film, the substrate is heated at 400°C, the deposition thickness is 70nm, and then the Ar + Ions were irradiated onto the film with an ion energy of 190keV and a dose of 1×10 17 ions / cm 2 .

[0032] The irradiated samples were then annealed in a conventional tubular annealing furnace under vacuum at a pressure of -4 Pa, for irradiated WO 3 , the annealing temperature was 500°C, kept for 1 hour, and then cooled naturally.

Embodiment 2

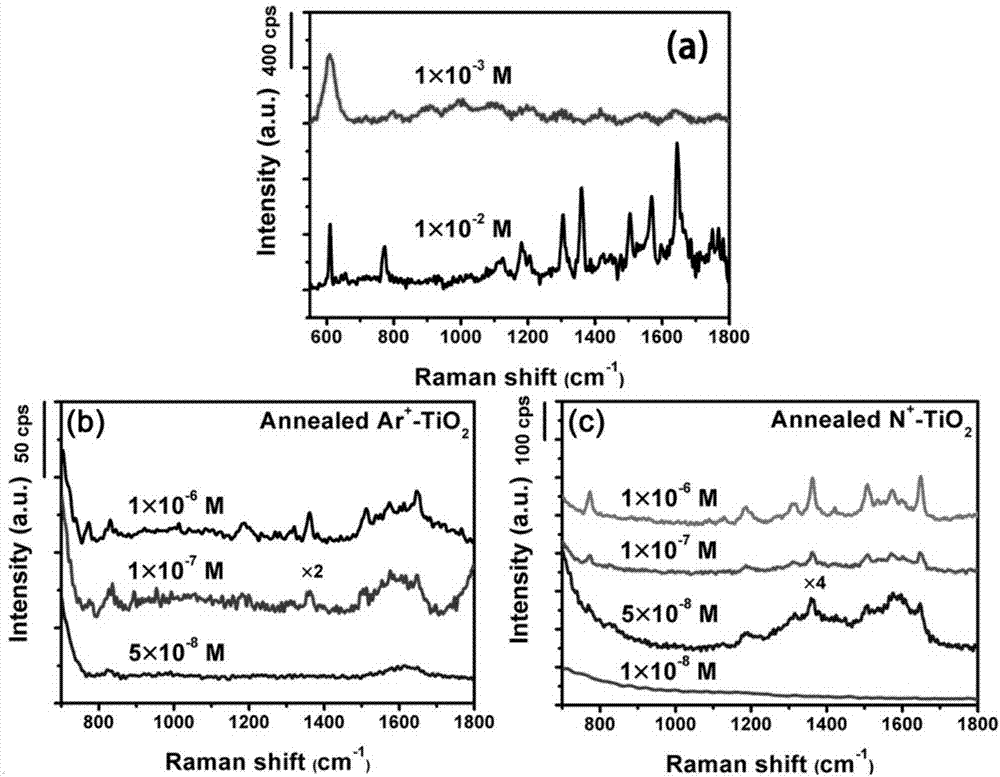

[0034] Using a 200kV ion implanter produced by Beijing Zhongkexin Electronic Equipment Co., Ltd., the energy was 50keV, and the dose was 1×10 17 ions / cm 2 Ar + Ion irradiation onto TiO 2 single crystal.

[0035] All irradiated samples were then annealed in a conventional tubular annealing furnace under vacuum at - 4 Pa, for irradiated TiO 2 , the annealing temperature was 500°C, kept for 1 hour, and then cooled naturally.

Embodiment 3

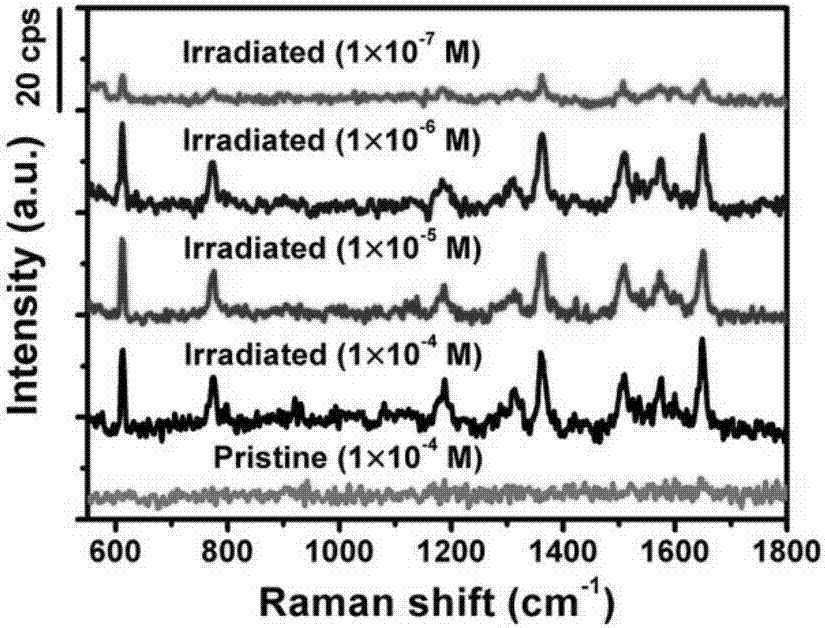

[0037] 45keV, dose 1×10 17 ions / cm 2 N + Ion irradiation onto TiO 2 single crystal.

[0038] All irradiated samples were then annealed in a conventional tubular annealing furnace under vacuum at - 4 Pa, for irradiated TiO 2 , the annealing temperature was 500°C, kept for 1 hour, and then cooled naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com