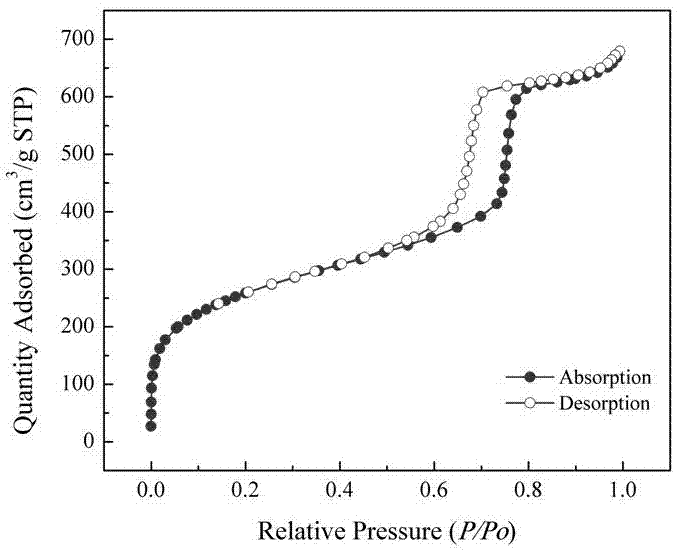

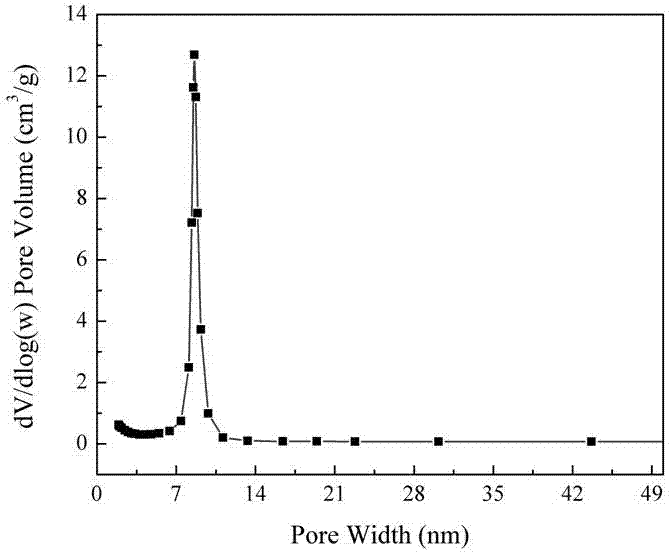

Titanium-doped mesoporous material Ti-SBA-15, and preparation method and application thereof

A mesoporous material and titanium doping technology, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve the problems of fast hydrolysis, affecting application performance, and high price, so as to achieve good adsorption performance and avoid structure Effect of inhomogeneity and uniform Ti distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

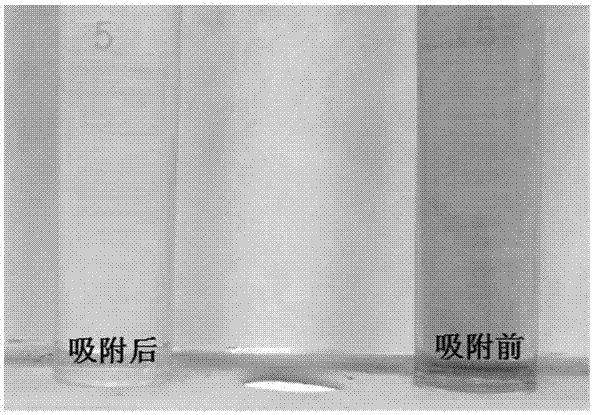

Examples

preparation example Construction

[0025] The preparation method of the titanium-doped mesoporous material involved in the present invention comprises the following steps:

[0026] Step 1: Dissolve 2.00g of triblock copolymer template agent P123—polyethylene glycol-polypropylene glycol-polyethylene glycol and 1.18g of NaCl in 60mL of deionized water, and stir in a water bath at 40°C until P123 is completely dissolved. Then add 4.5mL tetraethyl orthosilicate (TEOS) dropwise, and make the mixed solution stir and pre-hydrolyze for 4 hours under the condition of heating in a water bath at 40°C;

[0027] Step 2: Weigh 0.09-0.18 g of lactic acid, dissolve it in 20 mL of deionized water, and then add 0.48-0.96 g of Ti(SO 4 ) 2 Stir with a magnetic stirrer until the solution is transparent;

[0028] Step 3: Add the transparent solution obtained in Step 2 to Step 1, and then continue to hydrolyze for 24 hours under the condition of a water bath at 40°C.

[0029] Step 4: Transfer the hydrolyzed solution in Step 3 to a...

Embodiment 1

[0032] A titanium-doped mesoporous material Ti-SBA-15 and a preparation method thereof, comprising the steps of:

[0033] Step 1: Dissolve 2.00g of triblock copolymer template agent P123-polyethylene glycol-polypropylene glycol-polyethylene glycol and 1.18g of NaCl in 60mL of deionized water, and stir in a water bath at 40°C until P123 is completely dissolved. Then add 4.5mL tetraethyl orthosilicate (TEOS) dropwise, and make the mixed solution stir and pre-hydrolyze for 4 hours under the condition of heating in a water bath at 40°C;

[0034] Step 2: Weigh 0.18 g of lactic acid, dissolve it in 20 mL of deionized water, and then add 0.96 g of Ti(SO 4 ) 2 Stir with a magnetic stirrer until the solution is transparent;

[0035] Step 3: Add the transparent solution obtained in Step 2 to Step 1, and then continue to hydrolyze for 24 hours under the condition of a water bath at 40°C.

[0036] Step 4: Transfer the hydrolyzed solution in Step 3 to a polytetrafluoroethylene-lined aut...

Embodiment 2

[0043] Step 1: Dissolve 2.00g of triblock copolymer template agent P123-polyethylene glycol-polypropylene glycol-polyethylene glycol and 1.18g of NaCl in 60mL of deionized water, and stir in a water bath at 40°C until P123 is completely dissolved. Then add 4.5mL tetraethyl orthosilicate (TEOS) dropwise, and make the mixed solution stir and pre-hydrolyze for 4 hours under the condition of heating in a water bath at 40°C;

[0044] Step 2: Weigh 0.09 g of lactic acid, dissolve it in 20 mL of deionized water, and then add 0.48 g of Ti(SO 4 ) 2 Stir with a magnetic stirrer until the solution is transparent;

[0045] Step 3: Add the transparent solution obtained in Step 2 to Step 1, and then continue to hydrolyze for 24 hours under the condition of a water bath at 40°C.

[0046] Step 4: Transfer the hydrolyzed solution in Step 3 to a polytetrafluoroethylene-lined autoclave, and place it in an oven at 90°C for hydrothermal reaction for 24 hours. After the reaction, a white solid pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com