A novel structure biophilic and hydrophilic filter brush

A new structure, biophilic technology, applied in biological water/sewage treatment, filtration and separation, special compound water treatment, etc., can solve the problems of low sewage treatment efficiency and unsatisfactory film-hanging characteristics, and reduce the power consumption of oxygen exposure, The effect of increasing the film hanging characteristics and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 2

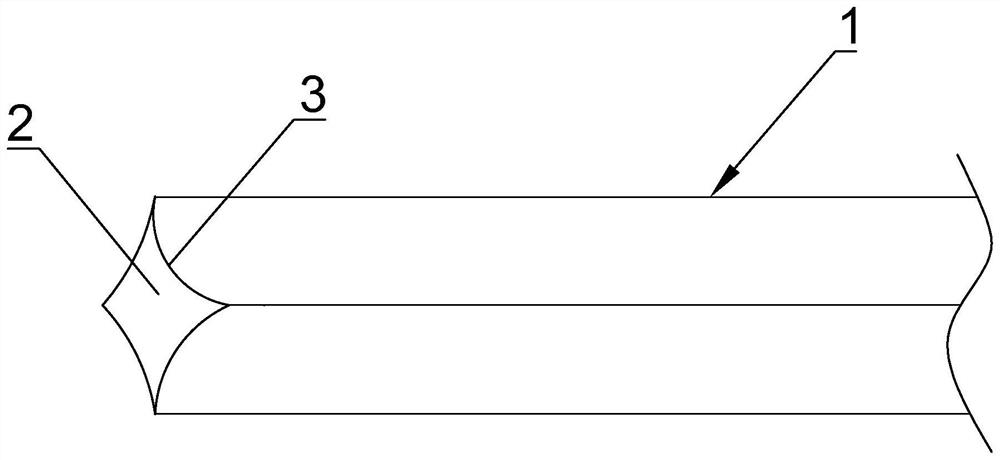

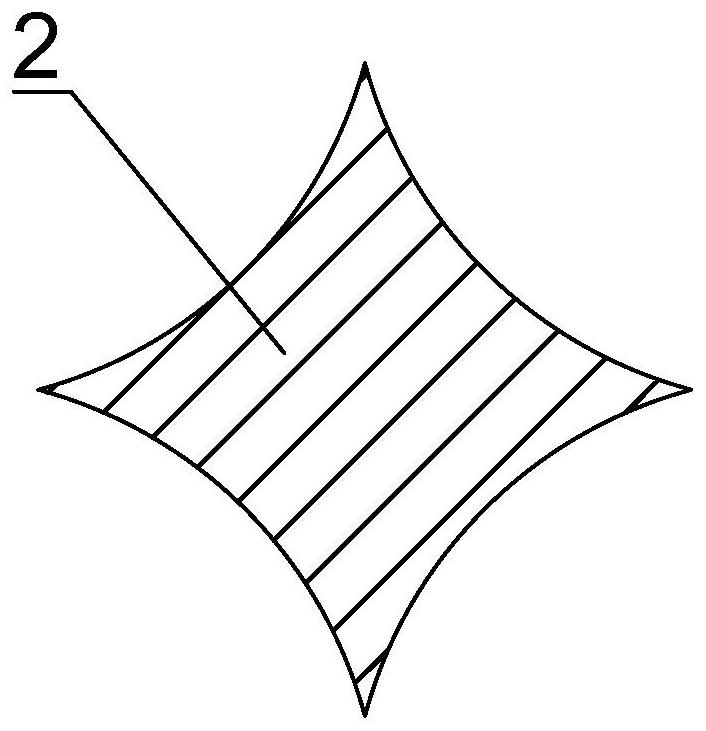

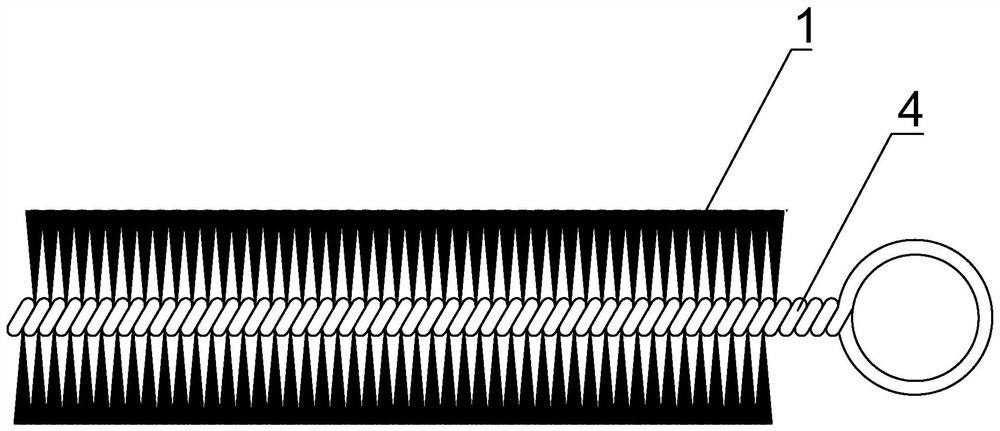

[0040] A biological and hydrophilic filter brush with a novel structure, the preparation method of which comprises the following steps: weighing the following raw materials according to mass percentage: PET 93kg, iron oxide 1.5kg, carbon powder 2.5kg, calcium sulfate 2.5kg, stearic acid Magnesium 0.5kg. After the PET raw material is dried, add iron oxide, carbon powder, calcium chloride and magnesium stearate into the PET and mix evenly, then send the evenly mixed material into the extruder barrel, and set the temperature of the extruder to 235°C , so that the actual temperature is controlled between 230°C and 240°C. After melt blending, it is extruded from a die with a cross-square rhombus in the cavity of the machine head, and the cross-section is cross-square rhombus after cooling, stretching and shaping. bristles. The bristles and stainless steel wires are mechanically shaped, sheared, and cut to length to make filter brushes of different lengths whose bristles are radial...

Embodiment example 3

[0042] A biological and hydrophilic filter brush with a novel structure, the preparation method of which comprises the following steps: weighing the following raw materials according to mass percentage: PP 89kg, iron oxide 2.5kg, carbon powder 3.5kg, calcium sulfate 3.5kg, stearic acid Magnesium 1.5kg. After the PP raw material is dried, add iron oxide, carbon powder, calcium sulfate and magnesium stearate into the PP and mix evenly, then send the evenly mixed material into the extruder barrel, set the temperature of the extruder to 210°C, The actual temperature is controlled between 200°C and 220°C, and after melt blending, it is extruded from a mold with a cross-square rhombus in the cavity of the machine head, and the bristles with a cross-section of a cross-square rhombus are obtained after cooling, stretching, and shaping . The bristles and stainless steel wires are mechanically shaped, sheared, and cut to length to make filter brushes of different lengths with bristles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com