Preparation method of CHDI-modified NDI-based polyurethane microcellular elastomer

A microporous elastomer and polyurethane technology, applied in the field of materials, can solve problems such as shortened service life, increased complexity of the reaction system, performance impact, etc., and achieve the goals of prolonging service life, improving photooxidation resistance, and improving wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

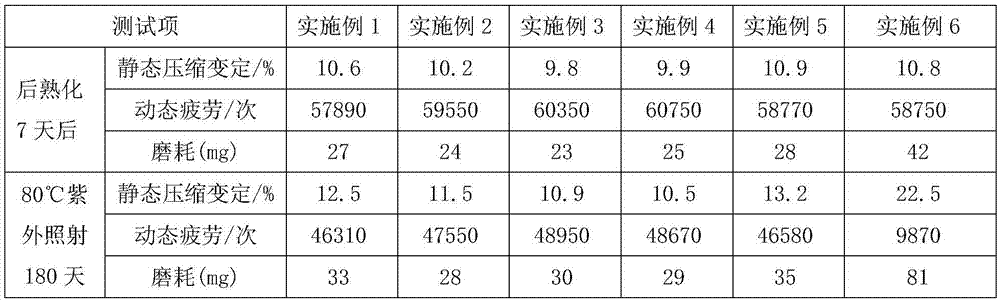

Examples

Embodiment 1

[0019] The specific method for preparing CHDI-modified NDI-based polyurethane microcellular elastomer in this embodiment is:

[0020] Mix 5 moles of NDI and 1 mole of CHDI evenly, and react with 2.723 moles of polyethylene adipate diol with a number average molecular weight of 1000 at 128°C for 25 minutes to obtain a terminal-NCO group content of 7wt%. terminal isocyanate prepolymer.

[0021] 100 mass parts of polyethylene adipate glycol with a number average molecular weight of 1000 and 10 mass parts of 1,4-butanediol, 6 mass parts of water, 0.8 mass parts of delayed catalyst (Dabco 1027), 0.8 parts by mass of a foam stabilizer (DabcoDC 2585) were mixed uniformly to prepare a chain extender composition.

[0022] Using a low-pressure foaming machine, the prepolymer and the chain extender composition are mixed and reacted according to the ratio of the isocyanate index of 95%, and the reaction liquid is injected into a mold at 90°C, aged for 25 minutes, demoulded, and then heat...

Embodiment 2

[0028] The specific method for preparing CHDI-modified NDI-based polyurethane microcellular elastomer in this embodiment is:

[0029] Mix 4 moles of NDI and 1 mole of CHDI evenly, and react with 1.765 moles of polycaprolactone diol with a number-average molecular weight of 2000 at 129° C. for 25 minutes to obtain a terminal isocyanate preprepared with a terminal-NCO group content of 6 wt%. Polymer.

[0030] 100 mass parts of polycaprolactone diol with a number average molecular weight of 2000 and 10 mass parts of 1,4-butanediol, 8 mass parts of water, 0.8 mass parts of retardation catalyst (Dabco 1027), 0.8 Mass parts of the foam stabilizer (Dabco DC 2585) were mixed uniformly to prepare a chain extender composition.

[0031] Using a low-pressure foaming machine, the prepolymer and the chain extender composition are mixed and reacted according to the ratio of the isocyanate index of 96%. After aging for 16 hours, a CHDI-modified NDI-based polyurethane microcellular elastomer...

Embodiment 3

[0033] The specific method for preparing CHDI-modified NDI-based polyurethane microcellular elastomer in this embodiment is:

[0034] Mix 4 moles of NDI and 1 mole of CHDI evenly, and react with 2.011 moles of polytetrahydrofuran ether diol with a number-average molecular weight of 2000 at 128°C for 25 minutes to prepare an isocyanate-terminated prepolymer with a terminal-NCO group content of 5 wt%. .

[0035] 100 parts by mass of polytetrahydrofuran ether glycol with a number average molecular weight of 2000, 10 parts by mass of 1,4-butanediol, water of 9 parts by mass, retardation catalyst (Dabco 1027) of 0.8 parts by mass, 0.8 parts by mass The foam stabilizer (Dabco DC2585) was mixed uniformly to prepare the chain extender composition.

[0036] Using a low-pressure foaming machine, the prepolymer and the chain extender composition are mixed and reacted according to the ratio of the isocyanate index to 96%. After aging for 16 hours, a CHDI-modified NDI-based polyurethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com