Hyperbranched polymer modified polyamide composite material and preparation method thereof

A hyperbranched polymer and composite material technology, applied in the field of hyperbranched polymer modified polyamide composite materials and its preparation, can solve the problems of low impact strength, small fiber length, limited performance improvement of nylon materials, etc., to improve processing properties, reduce viscosity, and improve surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

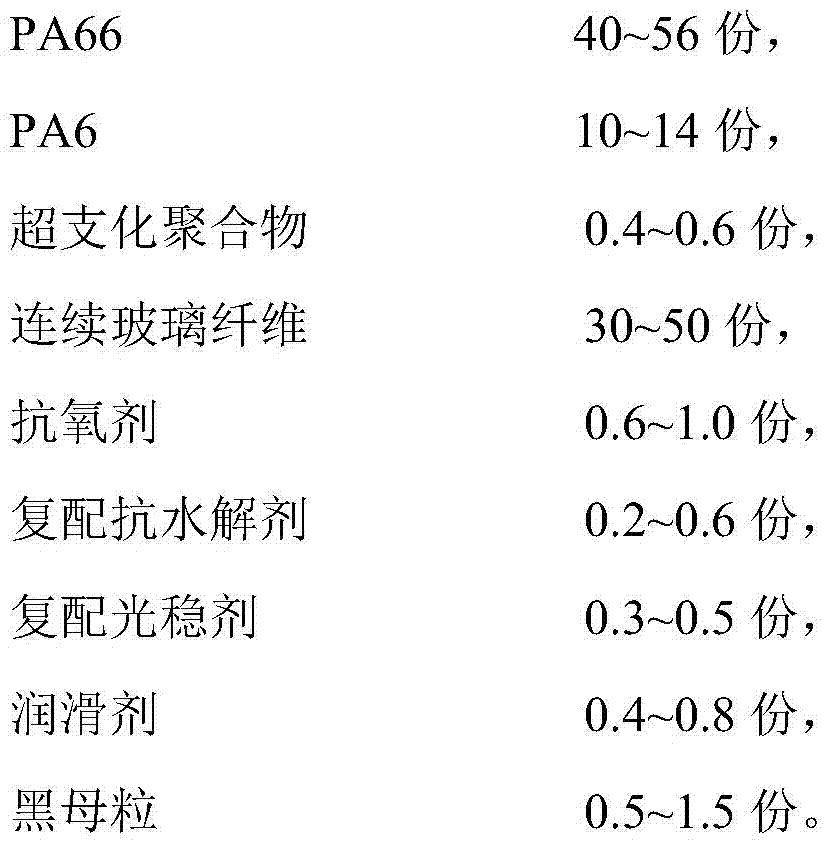

Method used

Image

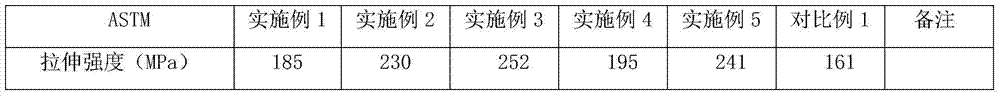

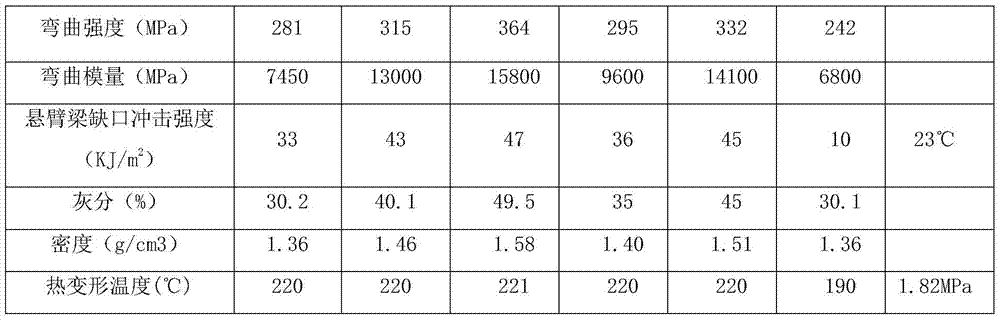

Examples

Embodiment 1

[0049] After drying 56 parts of PA66, 14 parts of PA6, 0.6 part of amine-terminated hyperbranched polyamide, 0.6 part of antioxidant (0.2 part of antioxidant 1098 and 0.4 part of antioxidant 168), 0.6 part of composite anti-hydrolysis agent ( 0.3 parts of polycarbodiimide and 0.3 parts of diisobutyl dithiophosphoroketone), 0.5 parts of composite light stabilizer (0.25 parts of UV531 and 0.25 parts of UV4050), 0.4 parts of lubricant (0.2 parts of ethylene-acrylic acid Copolymerized wax and 0.25 parts of calcium stearate), 0.5 parts of black masterbatch T09242, were sequentially added into the high mixer, and mixed at 40°C for 3 minutes.

[0050] Using melt impregnation pultrusion process, the above mixture is added to the hopper of a twin-screw extruder for heating and melting, wherein the diameter of the screw is 65mm, the length-to-diameter ratio of the screw is 40 / 1, and the mixing and melting temperature is set as: the first section 150°C, The second stage is 235°C, the thi...

Embodiment 2

[0052] With dried 48 parts of PA66, 12 parts of PA6, 0.5 part of amine-terminated hyperbranched polyamide, 0.9 part of antioxidant (0.3 part of antioxidant 1098 and 0.6 part of antioxidant 168), 0.4 part of composite anti-hydrolysis agent (0.2 0.2 parts of polycarbodiimide and 0.2 parts of diisobutyl dithiophosphoroketone), 0.4 parts of composite light stabilizer (0.2 parts of UV531 and 0.2 parts of UV4050), 0.6 parts of lubricant (0.3 parts of ethylene-acrylic acid copolymer Wax and 0.3 parts of silicone), 1.0 parts of black masterbatch T09242, were added to the high mixer in sequence, the mixing temperature was controlled at 40°C, and the mixing was carried out for 3 minutes.

[0053] Using melt impregnation pultrusion process, the above mixture is added to the hopper of a twin-screw extruder for heating and melting, wherein the diameter of the screw is 65mm, the length-to-diameter ratio of the screw is 40 / 1, and the mixing and melting temperature is set as: the first section...

Embodiment 3

[0055] With dried 40 parts of PA66, 10 parts of PA6, 0.4 part of amine-terminated hyperbranched polyamide, 1.0 part of antioxidant (0.34 part of antioxidant 1098 and 0.66 part of antioxidant 168), 0.2 part of composite anti-hydrolysis agent ( 0.1 part of polycarbodiimide and 0.1 part of diisobutyl dithiophosphoroketone), 0.3 part of composite light stabilizer (0.15 part of UV531 and 0.15 part of UV4050), 0.8 part of lubricant (0.4 part of pentaerythritol stearin Acetate and 0.4 parts of silicone), 1.5 parts of black masterbatch T09294, were added to the high mixer in sequence, the mixing temperature was controlled at 40°C, and the mixing was carried out for 3 minutes.

[0056] Using melt impregnation pultrusion process, the above mixture is added to the hopper of a twin-screw extruder for heating and melting, wherein the diameter of the screw is 65mm, the length-to-diameter ratio of the screw is 40 / 1, and the mixing and melting temperature is set as: the first section 150°C, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com