Dietary fiber-rich food capable of delaying blood glucose elevation and processing method of dietary fiber-rich food

A dietary fiber and food technology, applied in the field of dietary fiber-rich food and its processing, can solve the problems of difficult rehydration and softening, protein content reduction, difficult processing and molding, etc., to enhance intestinal health, reduce oil content, and easy to solve Fracture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

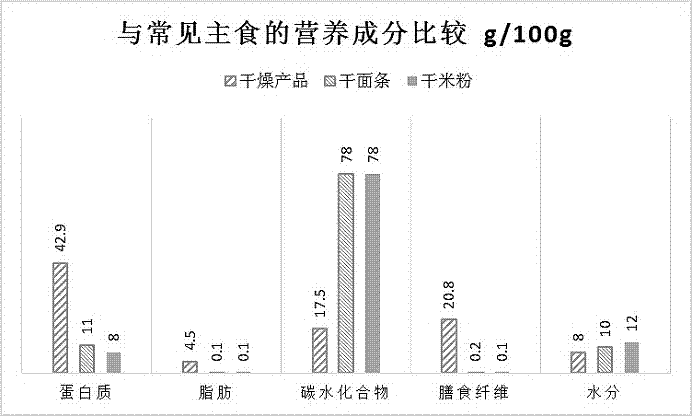

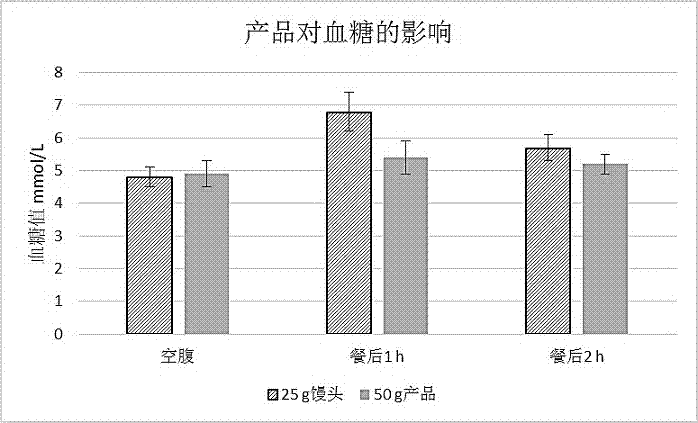

[0037] Example 1: Take 100 kg of soybeans, go through winnowing and polishing to remove impurities, add 10 kg of chia seeds and 5 kg of sesame seeds, mix and squeeze the oil with a low-temperature screw, and the oil content of the cake is 7%. The cake and 35 kg of oat bran were ultrafinely pulverized with a particle size of 200 mesh. After all the powders are mixed, add 70 kg of purified water and mix well. Set the temperature of the screw extruder at 120°C, 160°C and 180°C, start it after preheating, set the speed at 30 r / min initially, add the premixed material, and turn on the cooling water circulation after the strip material at the exit is smoothly extruded. The speed is set at 35 r / min. The strip material was dried by hot air at 70 ℃ to a moisture content of 8%. Cut into uniform length products with a strip cutter and pack. Through the determination of nutritional components, the comparison between this product and dry noodles and dry rice noodles is as good as figur...

example 2

[0038] Example 2: Take 100 kg of black soybeans, go through air selection and polishing to remove impurities, add 5 kg of walnut kernels, and after mixing, squeeze the oil by low-temperature screw extrusion, and the oil content of the cake is 10%. The cake and 5 kg of wheat bran were ultrafinely pulverized to a particle size of 200 mesh. After all the powders are mixed, add 50 kg of purified water and mix well. Set the temperature of the screw extruder at 120°C, 160°C and 180°C, start it after preheating, set the speed at 30 r / min initially, add the premixed material, and turn on the cooling water circulation after the strip material at the exit is smoothly extruded. The speed is set at 35 r / min. The strip material was dried by hot air at 70 ℃ to a moisture content of 8%. Cut into uniform length products with a strip cutter and pack. The nutritional components of the product under this condition were protein 47.4 g / 100g, fat 8.2 g / 100g, carbohydrate 15.2 g / 100g, and dietary...

example 3

[0039] Example 3: Take 100 kg of soybeans, go through winnowing and polishing to remove impurities, and press the oil with low-temperature screw extrusion, and the oil content of the cake is 6%. 15 kg of dehydrated tomato and 20 kg of oat bran were ultrafinely pulverized to a particle size of 200 mesh. After all the powders are mixed, add 70 kg of purified water and mix well. Set the temperature of the screw extruder at 120°C, 160°C and 180°C, start it after preheating, set the speed at 30 r / min initially, add the premixed material, and turn on the cooling water circulation after the strip material at the exit is smoothly extruded. The speed is set at 35 r / min. The strip material was dried by hot air at 70 ℃ to a moisture content of 8%. Cut into uniform length products with a strip cutter and pack. The nutritional components of the product under this condition were protein 36.6 g / 100g, fat 3.2 g / 100g, carbohydrate 24.8 g / 100g, and dietary fiber 24.7 g / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com