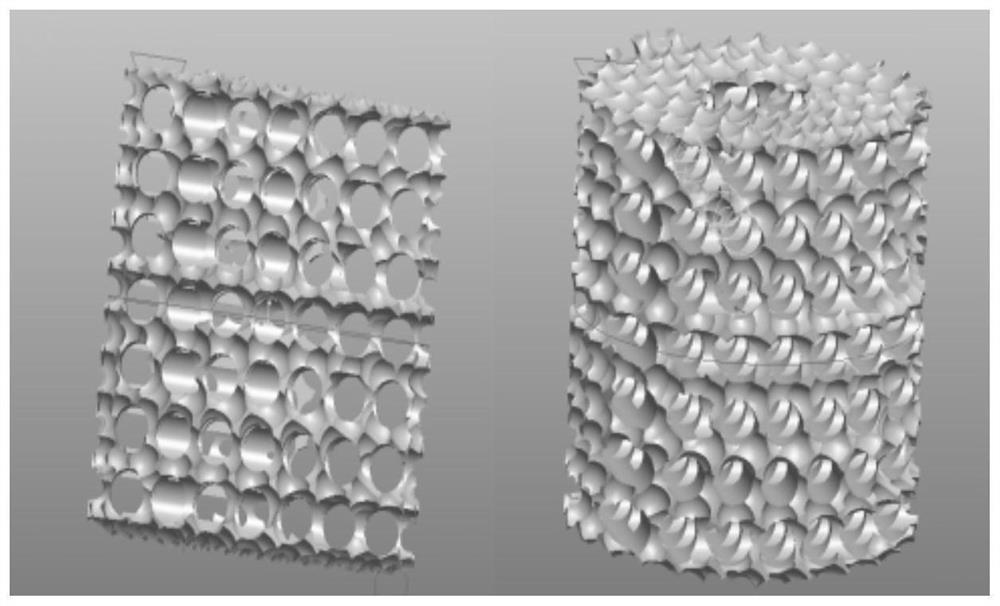

An individualized and customized zirconia porous biological bone repair scaffold based on light-curing 3D printing technology and its preparation method

A 3D printing and zirconium dioxide technology, applied in prosthesis, pharmaceutical formula, tissue regeneration, etc., can solve problems such as the inability to solve scaffold manufacturing problems, and achieve the effects of short manufacturing process time, high efficiency, and precise porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

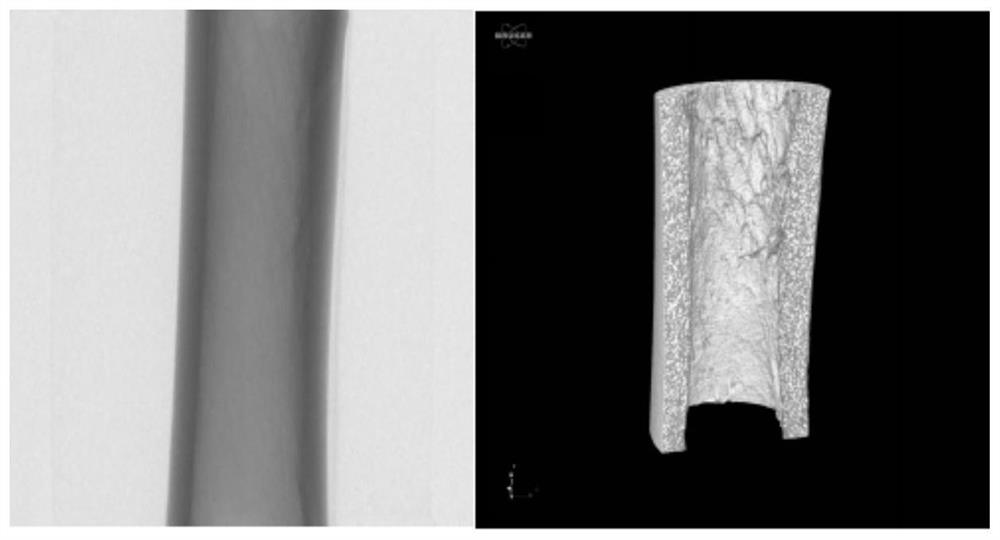

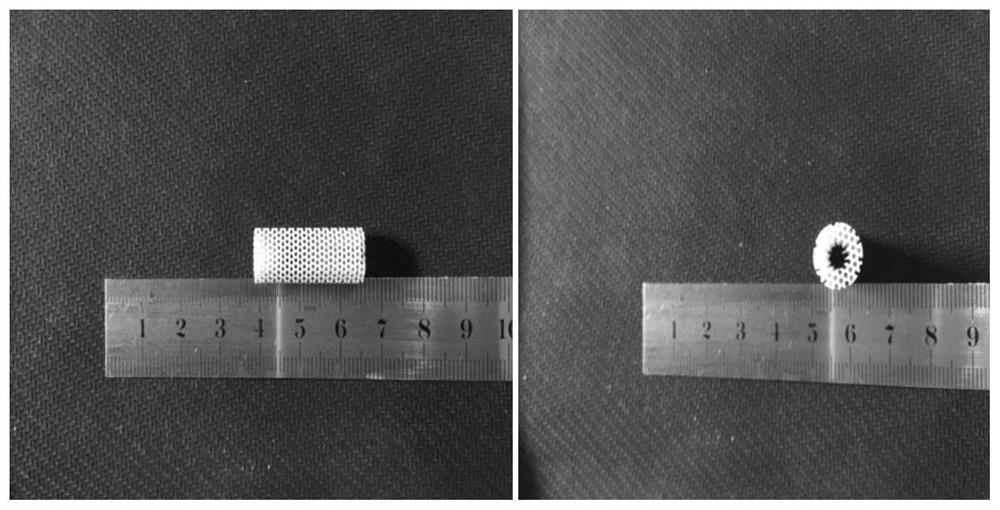

[0032] The following canine femoral shaft HA / ZrO 2 The bioceramic scaffold material is taken as an example to describe the present invention in detail.

[0033] 1.1 Animal model of femoral shaft defect

[0034]Male adult Beagle dogs weighing 7.3±1.2 kg were used in the experiment. According to the critical value of canine femoral diaphysis bone defect of 15 mm, 15 mm of the middle section of canine femur was amputated in the experiment to establish the femoral diaphysis defect model. Operation method: Fasting for 12 hours before the operation, intravenous anesthesia with 3% pentobarbital sodium (1 ml / kg), after anesthesia, endotracheal intubation, and continuous oxygen inhalation during the operation. The skin in the surgical area was depilated, cleaned, disinfected, and draped. An incision about 8 cm in the lateral femur of the right lower extremity was taken, and the skin and subcutaneous tissue were cut layer by layer. Hemostasis was achieved by electrocoagulation. The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com