Catalyst for producing methylal by one-step oxidation of methanol and its preparation method and application

A catalyst and methylal technology, which is applied in the field of one-step methanol oxidation to methylal catalyst and its preparation, can solve the problems of lower reaction economy, increased selectivity of carbon monoxide and carbon dioxide, and no DMM, etc., and achieve a good degree of dispersion , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

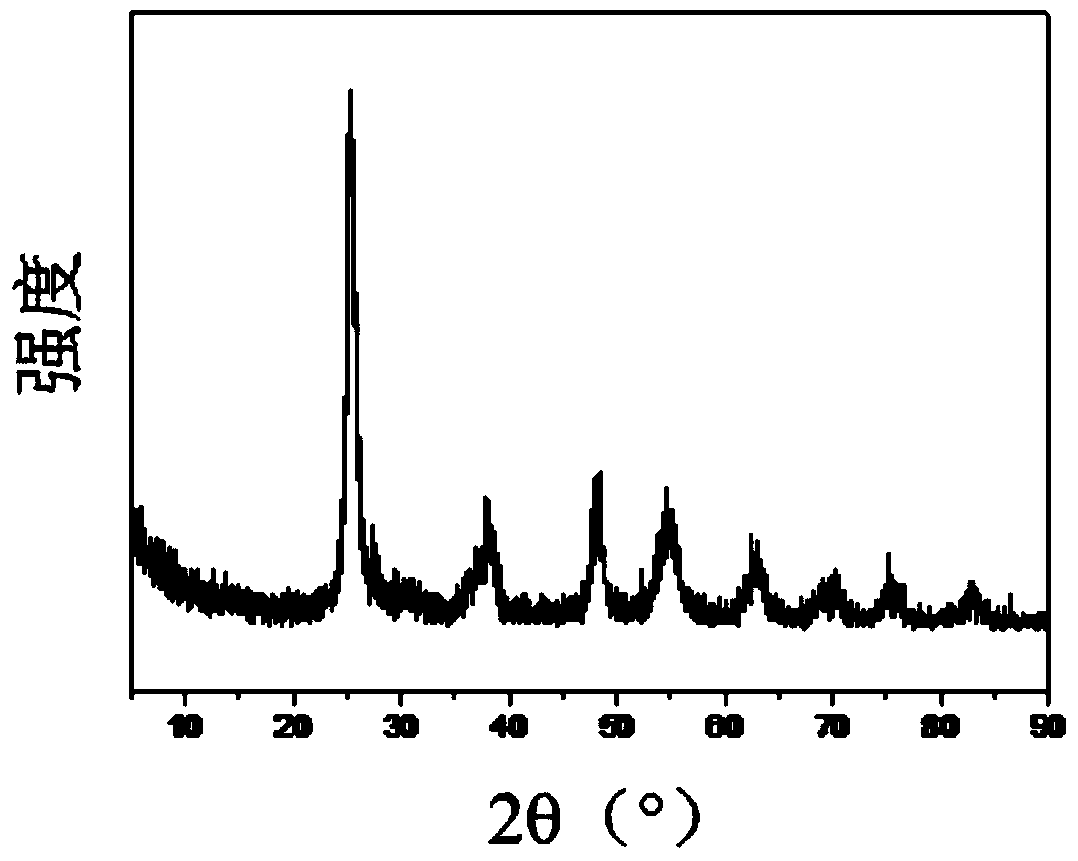

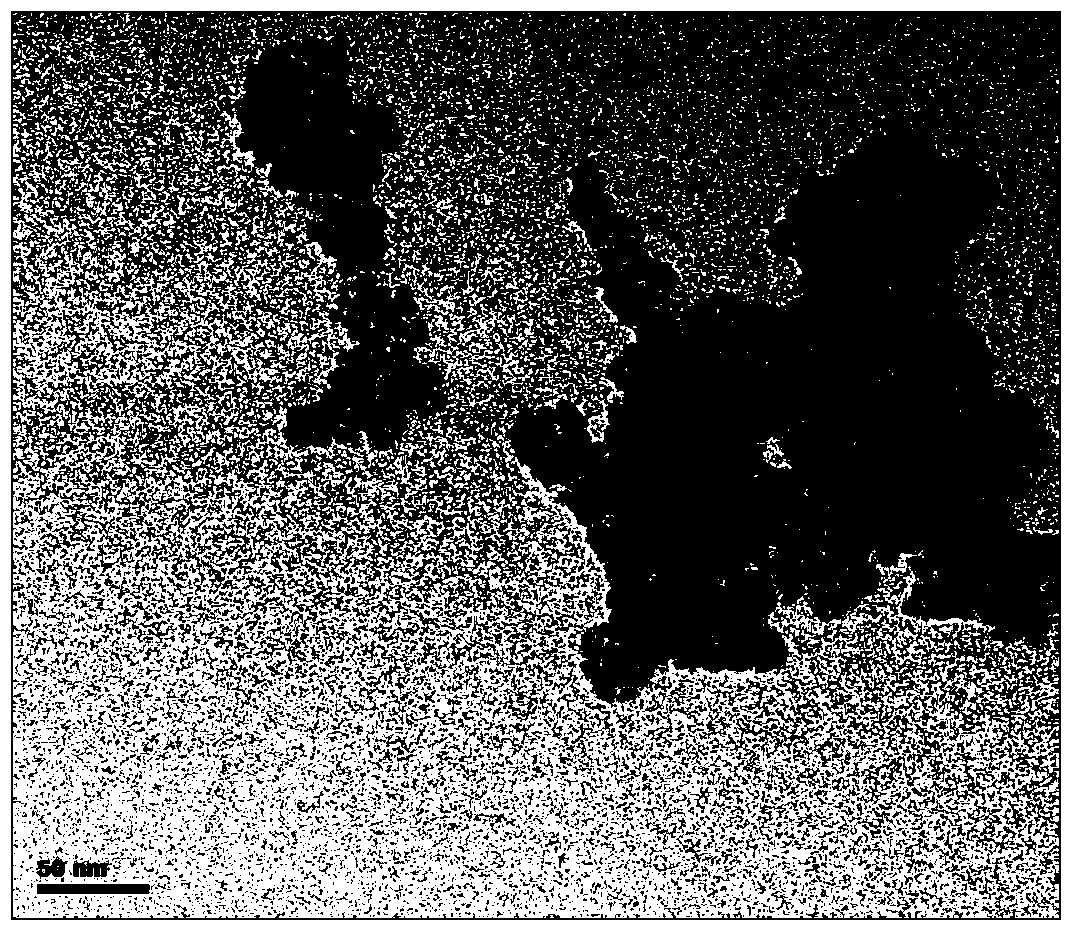

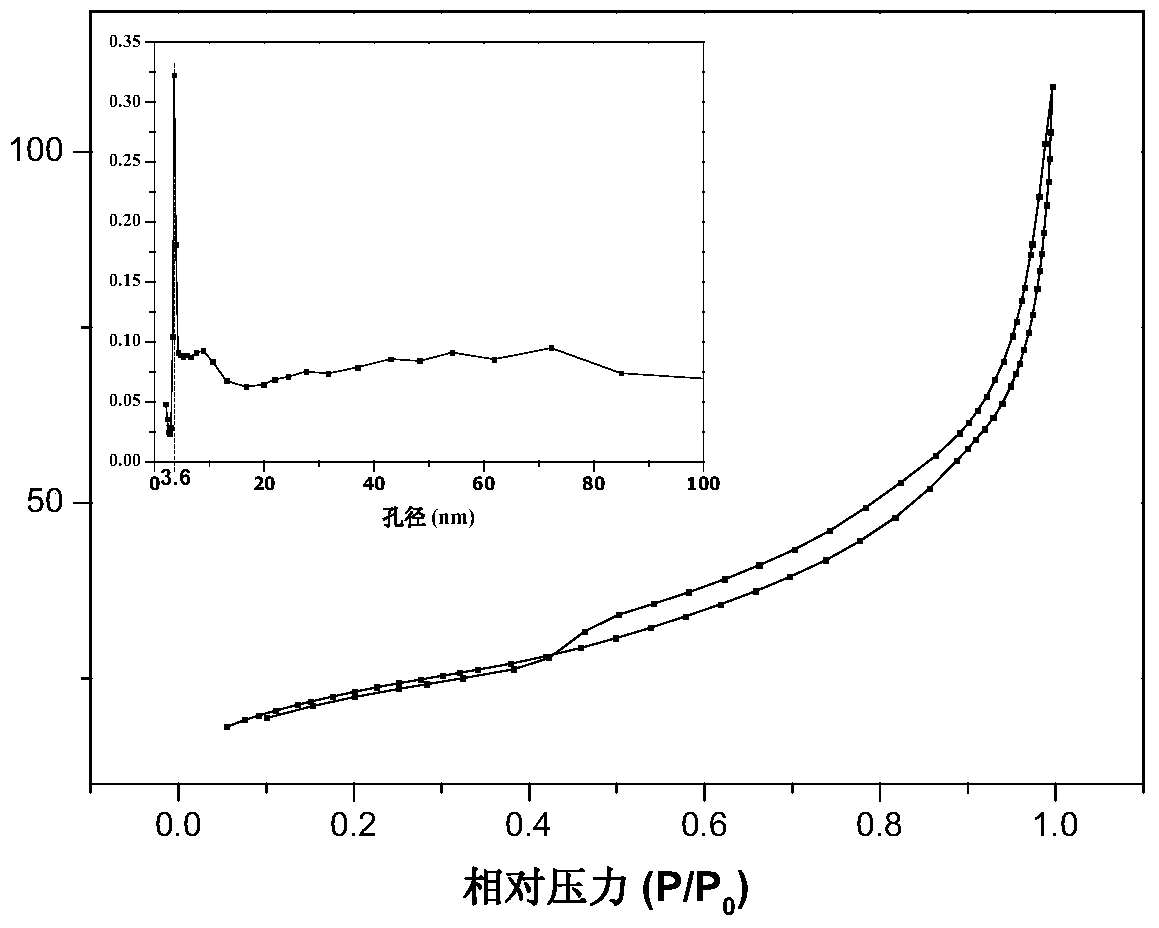

[0045] Dissolve 4.0g vanadyl sulfate and 17.4g titanium sulfate in a three-necked flask filled with 300ml deionized water, and dissolve under stirring to obtain solution A; dissolve 15g cetyltrimethylammonium bromide (CTAB) in 500ml Heat and stir in deionized water for 30 minutes to obtain solution B; drop mixed solution A into solution B at a speed of 80 r / min to obtain mixed solution C containing preliminary precipitation. 40ml of ammonia water (25%) was dissolved in 360ml of deionized water to prepare an ammonia solution. Place C under an ice-water bath and stir vigorously, and drip an ammonia solution into the mixture C at a speed of 80 r / min until pH = 9.0, and obtain a slurry containing two-step precipitation, which is yellow-brown. Continue to stir for 0.5h, then leave it to age for 2h, wash it twice with 100ml of water, and filter with suction to get a tan filter cake, dry the filter cake at 110°C for 2h to get solid D, and roast solid D at 400°C After 6h, the catalys...

Embodiment 2

[0054] Dissolve 4.0g of vanadyl sulfate and 17.4g of titanium sulfate in a three-necked flask filled with 300ml of deionized water, and dissolve under stirring to obtain solution A; dissolve 25g of CTAB in 500ml of deionized water, heat and stir for 30min to obtain solution B; Mixed solution A was dropped into solution B at a speed of 80 r / min to obtain mixed solution C containing preliminary precipitation. 40ml of ammonia water (25%) was dissolved in 360ml of deionized water to prepare an ammonia solution. Place C under an ice-water bath and stir vigorously, and drip an ammonia solution into the mixture C at a speed of 80 r / min until pH = 9.0, and obtain a slurry containing two-step precipitation, which is yellow-brown. Continue to stir for 0.5h, then leave it to age for 2h, wash it twice with 100ml of water, and filter with suction to get a tan filter cake, dry the filter cake at 110°C for 2h to get solid D, and roast solid D at 400°C After 6h, the catalyst for the selectiv...

Embodiment 3

[0060] Dissolve 4.0g of vanadyl sulfate and 17.4g of titanium sulfate in a three-necked flask filled with 300ml of deionized water, and dissolve under stirring to obtain solution A; dissolve 35g of CTAB in 500ml of deionized water, heat and stir for 30min to obtain solution B; Mixed solution A was dropped into solution B at a speed of 80 r / min to obtain mixed solution C containing preliminary precipitation. 40ml of ammonia water (25%) was dissolved in 360ml of deionized water to prepare an ammonia solution. Place C under an ice-water bath and stir vigorously, and drip an ammonia solution into the mixture C at a speed of 80 r / min until pH = 9.0, and obtain a slurry containing two-step precipitation, which is yellow-brown. Continue to stir for 0.5h, then leave it to age for 2h, wash it twice with 100ml of water, and filter with suction to get a tan filter cake, dry the filter cake at 110°C for 2h to get solid D, and roast solid D at 400°C After 6h, the catalyst for the selectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com