Graphene/(040) crystal face bismuth vanadate heterojunction and preparation method and application thereof

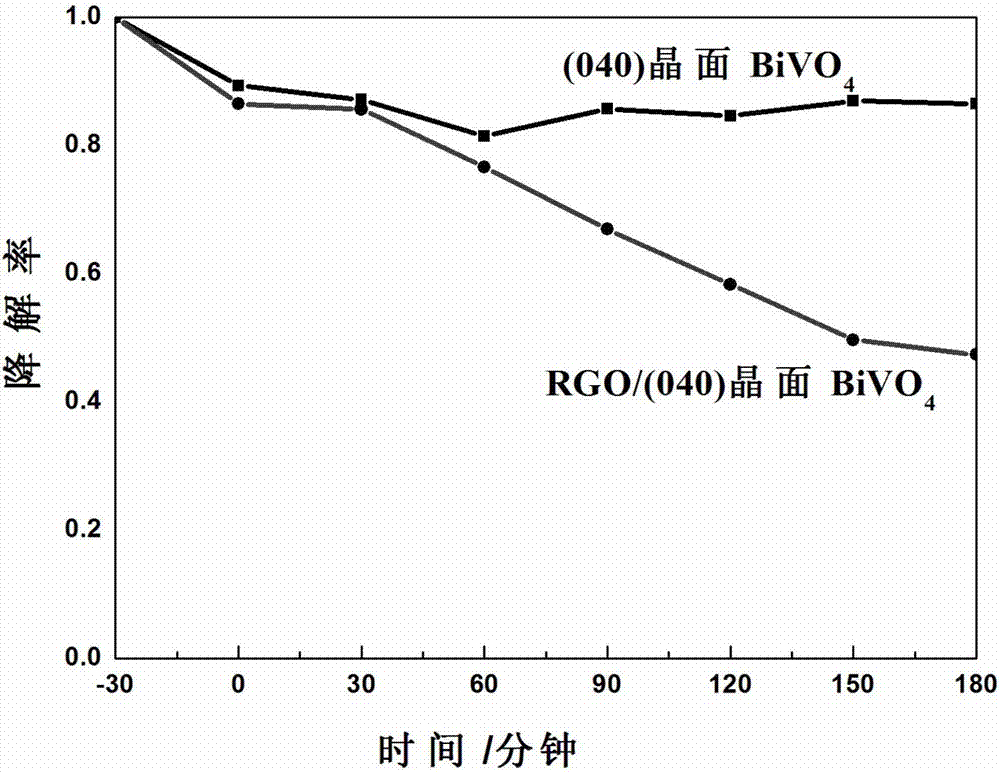

A technology of bismuth vanadate and graphene, which is applied in the field of RGO/crystal plane BiVO4 heterojunction and its preparation, can solve the problems of no reports, no patents and literature reports, etc., to improve quantum efficiency and photocatalytic activity And the effect of stability and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, 6mmoL Bi(NO 3 ) 3 ·5H 2 O dissolves in 1mol / L HNO at a uniform and slow speed under stirring 3 solution, stirred for 30min and slowly added 6mmoL NH 4 VO 3 , stirred for 60min to form precursor solution A, Bi in precursor solution A 3+ The concentration is 0.2mol / L;

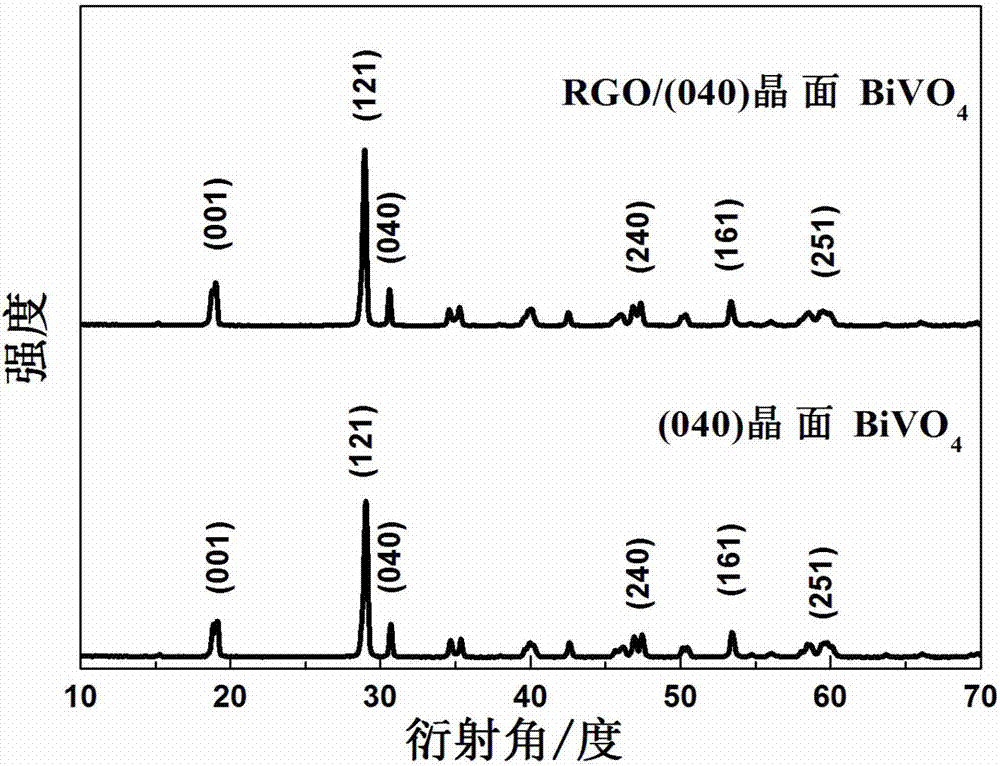

[0031] Step 2, Precursor solution A was hydrothermally reacted at 80°C for 15 hours to prepare (040) crystal plane BiVO 4 Precipitate, the precipitate was washed with alcohol and water, and then dried at 70°C for 9 hours to obtain (040) crystal plane BiVO 4 Powder;

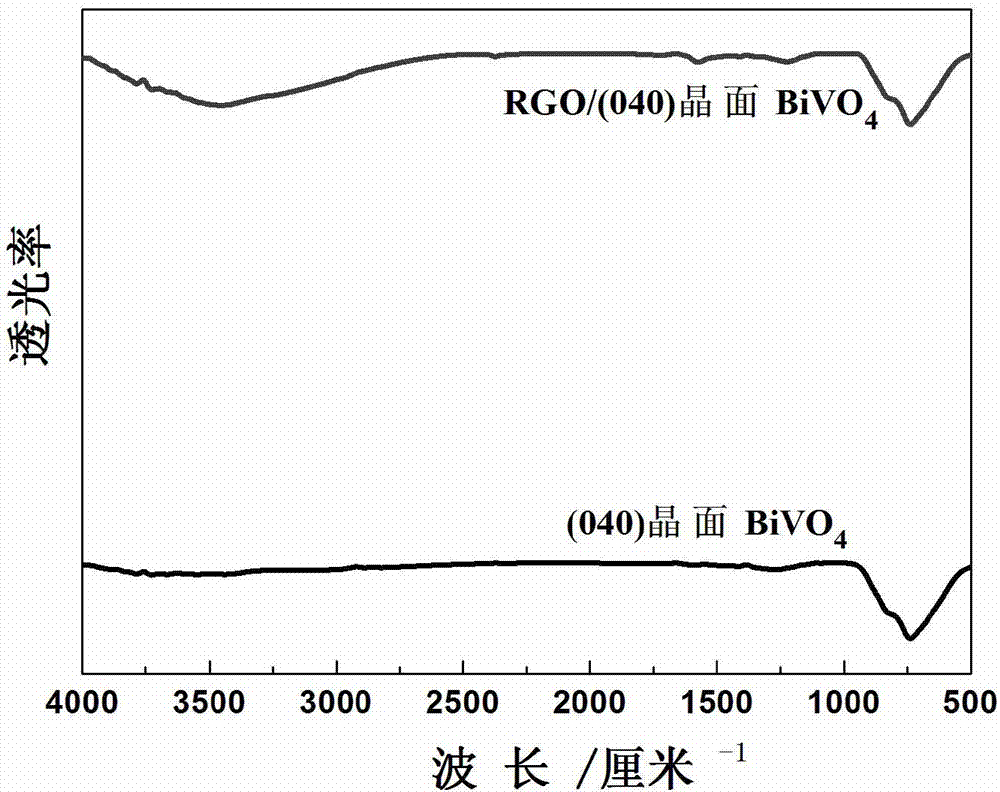

[0032] Step 3, the graphene oxide (GO) prepared by the improved Hummers method was dissolved in an aqueous ethanol solution with a volume fraction of 50%, ultrasonically dispersed at 50°C with a power of 100W for 60min, stirred for 10min, and then 1 drop / sec Add 2mol / L HNO at the speed 3 , ultrasonication at 50°C with a power of 100W for 60min, stirring for 10min, then adding 2mol / L NaOH solution at a rate of 1 drop / second, ul...

Embodiment 2

[0035] Step 1, 6mmoL Bi(NO 3 ) 3 ·5H 2 O dissolves in 1.8mol / L HNO at a uniform and slow speed under stirring conditions 3 solution, stirred for 30min and slowly added 6mmoL NH 4 VO 3 , stirred for 90min to form precursor solution A, Bi in precursor solution A 3+ The concentration is 0.18mol / L;

[0036] Step 2, Precursor solution A was hydrothermally reacted at 78°C for 13.5h to prepare (040) crystal plane BiVO 4 Precipitate, the precipitate was washed with alcohol and water, and then dried at 72°C for 9 hours to obtain (040) crystal plane BiVO 4 Powder;

[0037] Step 3, dissolve the prepared graphene oxide (GO) in 40% ethanol aqueous solution by volume fraction, ultrasonically disperse for 72min with a power of 80W at 40°C, stir for 15min, and then add 3mol / LHNO 3 , sonicated at 40°C with a power of 80W for 72min, stirred for 15min, then added 3mol / L NaOH solution at a rate of 2 drops / second, ultrasonicated at 40°C with a power of 80W for 72min, stirred for 15min, a...

Embodiment 3

[0040] Step 1, 6mmoL Bi(NO 3 ) 3 ·5H 2 O dissolves in 1.2mol / L HNO at a uniform and slow speed under stirring 3 solution, stirred for 30min and slowly added 6mmoL NH 4 VO 3 , stirred for 75min to form precursor solution A, Bi in precursor solution A 3+ The concentration is 0.22mol / L;

[0041] Step 2, Precursor solution A was hydrothermally reacted at 82°C for 14.5h to prepare (040) crystal plane BiVO 4 Precipitate, the precipitate was washed with alcohol and water, and then dried at 68°C for 9 hours to obtain (040) crystal plane BiVO 4 Powder;

[0042] Step 3: Dissolve the prepared graphene oxide (GO) in an aqueous ethanol solution with a volume fraction of 50%, ultrasonically disperse it at 45°C with a power of 90W for 75min, stir for 20min, and then add 4mol / LHNO 3 , sonicated at 45°C with a power of 90W for 75min, stirred for 20min, then added 4mol / L NaOH solution at a rate of 3 drops / second, ultrasonicated at 45°C with a power of 90W for 75min, and stirred for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com