Catalyst for low-temperature catalytic combustion of chlorine-containing organic matters, preparation method and application thereof

A technology of low-temperature catalysis and organic matter, applied in the direction of physical/chemical process catalysts, combustion methods, chemical instruments and methods, etc., can solve the problems of high-temperature active component loss, high price, chlorine poisoning, etc., and achieve high catalytic activity and preparation Simple, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

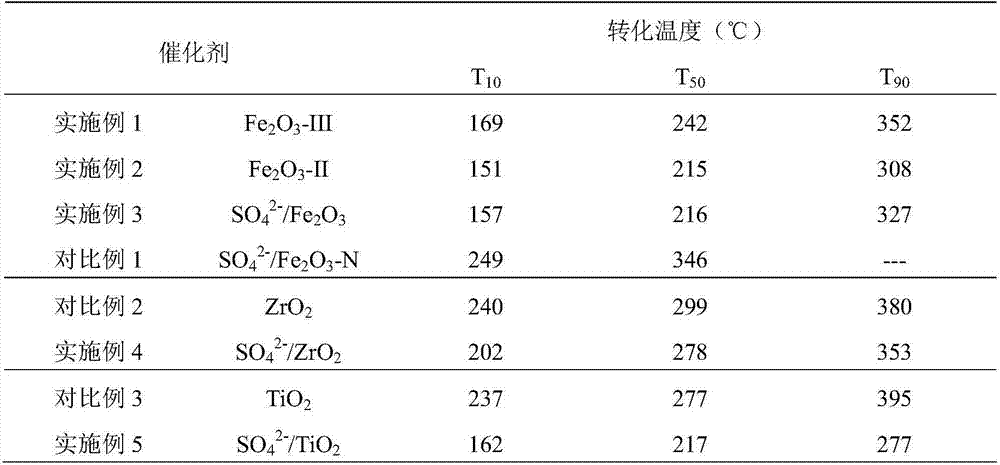

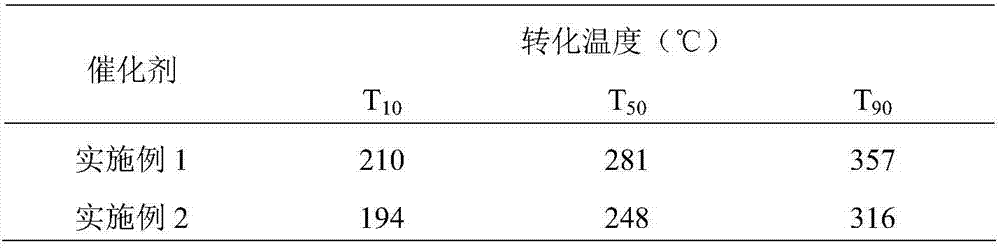

Embodiment 1

[0020] Dissolve 8.0g of ferric sulfate in 200mL of deionized water, slowly add ammonia solution dropwise, adjust the pH value of the solution to 9-10, stir vigorously for 2 hours, leave it at room temperature for 8 hours, then filter with suction, then wash with deionized water until the filtrate is Neutral, the filter cake was dried overnight at 110°C in an oven to obtain orange FeOOH (confirmed by XRD). Finally, FeOOH was put into a muffle furnace and calcined at 500°C for 4 hours in an air atmosphere to obtain Fe 2 o 3 -III Catalyst. Photoelectron spectroscopy and plasmon emission spectroscopy characterizations indicated that Fe 2 o 3 The -III catalyst contains 0.49wt% S, and the infrared spectrogram (KBr pellet) shows that the S species is in the form of bidentate bridge sulfate.

Embodiment 2

[0022] Dissolve 11.12g of ferrous sulfate heptahydrate in 200mL of deionized water, slowly add ammonia solution dropwise, adjust the pH value of the solution to 9-10, stir vigorously for 2 hours, leave it at room temperature for 8 hours, then suction filter, and then wash with deionized water Until the filtrate was neutral, the filter cake was dried overnight at 110°C in an oven to obtain yellow-orange FeOOH (confirmed by XRD). Finally, FeOOH was put into a muffle furnace and calcined at 500°C for 4 hours in an air atmosphere to obtain Fe 2 o 3 -II catalyst. Photoelectron spectroscopy and plasmon emission spectroscopy characterizations indicated that Fe 2 o 3 The -II catalyst contains 1.15wt% S, and the infrared spectrogram (KBr pellet) shows that the S species is in the form of bidentate boiled sulfate.

Embodiment 3

[0024] Take 1.5mL of 0.02g / mL sulfuric acid solution, impregnate 3g of dry orange FeOOH powder in Example 1, let it stand at room temperature for 6h, place it in an oven to dry overnight at 110°C, and then bake it in a muffle furnace at 500°C for 4h in an air atmosphere. end up with SO 4 2- / Fe 2 o 3 catalyst. Photoelectron spectroscopy and plasma emission spectroscopy characterizations indicated that SO 4 2- / Fe 2 o 3 The catalyst contains 1.42wt% S, and the infrared spectrogram (KBr pellet) shows that the S species is in the form of bidentate bridged sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com