Preparation method of fayalite

A technology of fayalite and pressing into blocks, which is applied in the direction of inorganic chemistry, silicon compounds, non-metallic elements, etc., can solve the problems of difficult to realize industrial production, low product purity, harsh reaction conditions, etc., and achieve low equipment requirements and high purity High, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

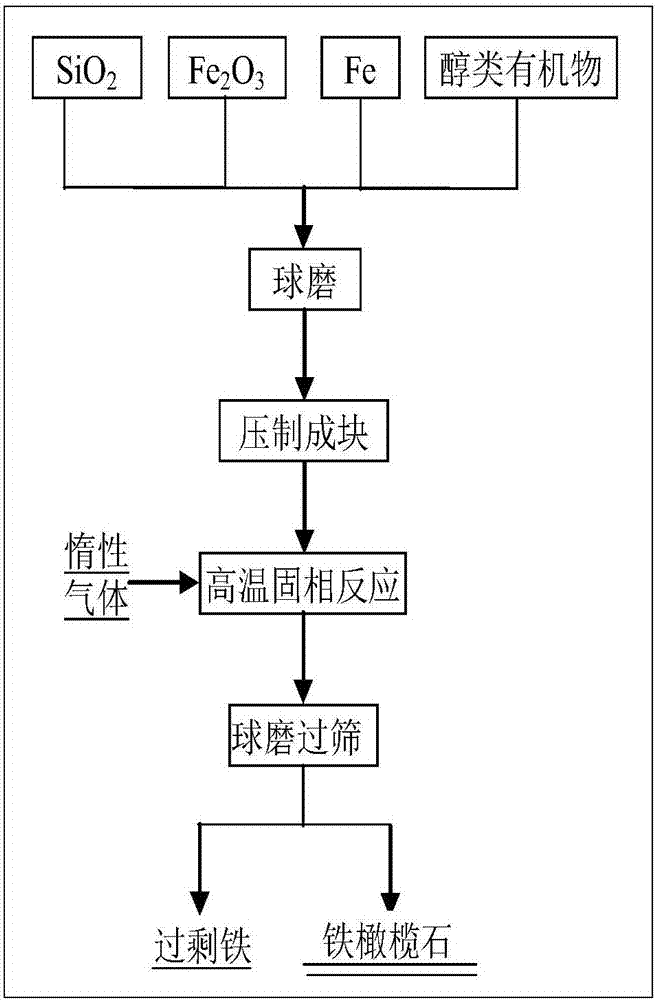

Method used

Image

Examples

Embodiment 1

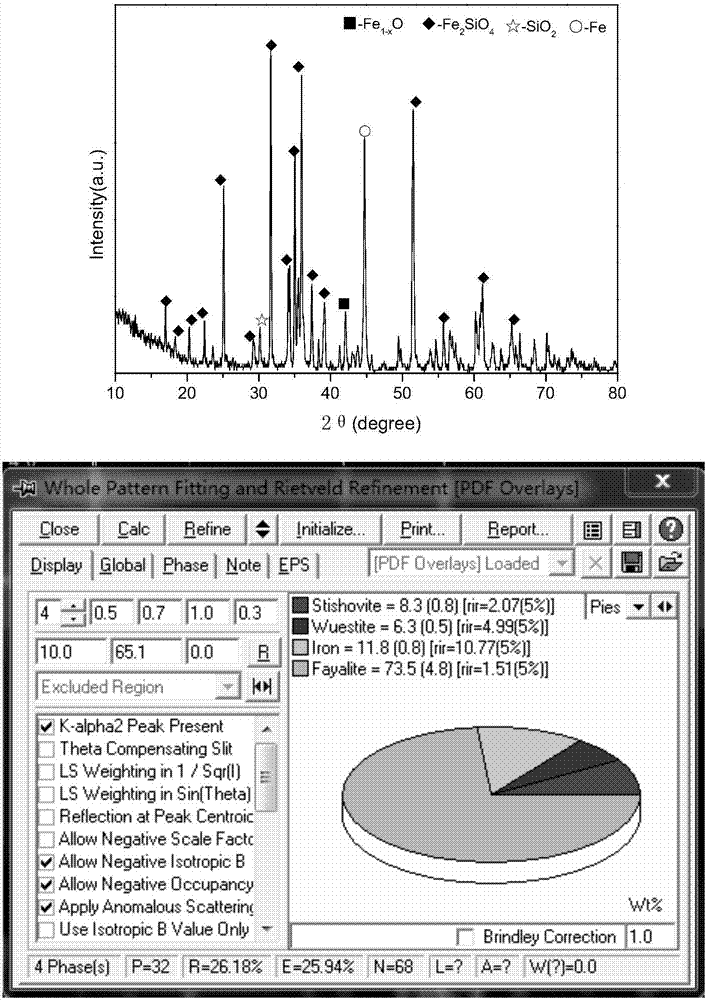

[0029] Fe, Fe 2 o 3 and SiO 2 Weigh 20g of raw materials according to the molar ratio of 3:2:3, measure 2ml of absolute ethanol, mix and ball mill, then press into blocks under a pressure of 20MPa, put the block raw materials into an atmosphere tube furnace, and feed inert gas in Under the condition of 1100 ℃, carry out high-temperature solid-state reaction for 180 minutes. After cooling, the crushing ball mill passes through a 200-mesh sieve, and then undergoes magnetic separation. The non-magnetic material is the product fayalite. Synthetic fayalite XRD pattern as shown figure 2 As shown, the fayalite content in the synthetic product is more than 95.3%, and the remaining 4.7% is Fe 1-x O, SEM images of reaction raw materials and synthesized fayalite image 3 shown.

Embodiment 2

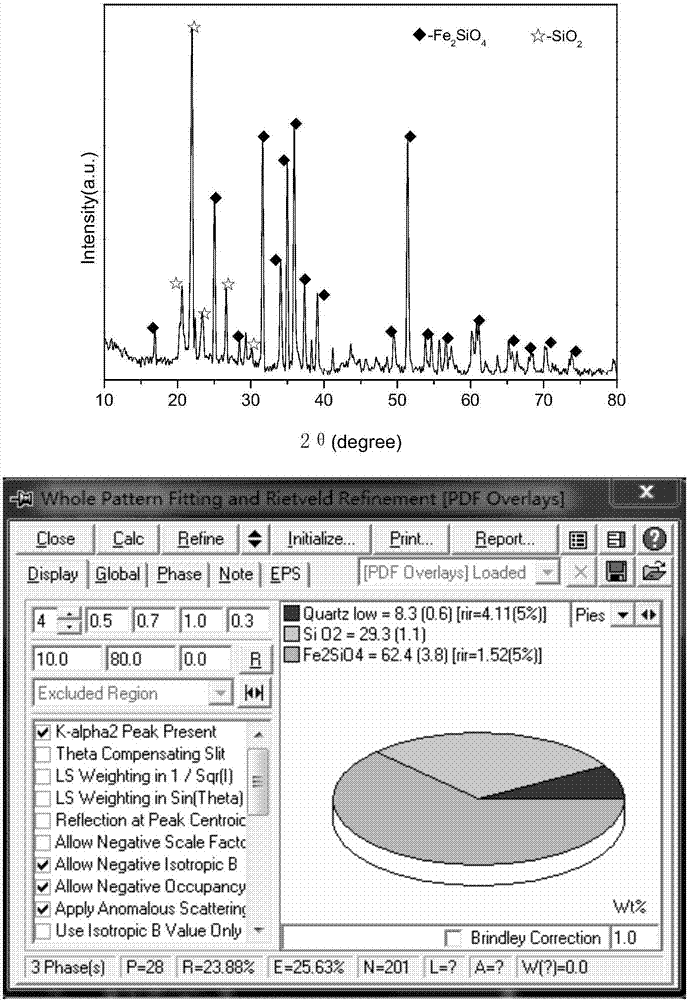

[0031] Fe, Fe 2 o 3 and SiO 2 Take by weighing 20g of raw materials according to the molar ratio of 4:2:3, measure 4ml of absolute ethanol, mix and ball mill, then press into blocks under a pressure of 40MPa, put the block raw materials into an atmosphere tube furnace, and feed inert gas in Under the condition of 1000 ℃, carry out high-temperature solid-state reaction for 240 minutes, after cooling, crush ball mill and pass through a 200-mesh sieve, and then carry out magnetic separation and separation. The non-magnetic material is the product fayalite. The fayalite content in the synthetic product is over 96%, and the main crystal phase is Fe 2 SiO 4 .

Embodiment 3

[0033] Fe, Fe 2 o 3 and SiO 2 Take by weighing 20g of raw materials according to the molar ratio of 5:2:3, measure 6ml of absolute ethanol, mix and ball mill, then press into blocks under a pressure of 50MPa, put the block raw materials into an atmosphere tube furnace, and feed inert gas in Under the condition of 1200°C, carry out high-temperature solid-state reaction for 120 minutes. After cooling, it is crushed and ball-milled through a 200-mesh sieve, and then separated by magnetic separation. The non-magnetic material is the product fayalite. The fayalite content in the synthetic product is over 96%, and the main crystal phase is Fe 2 SiO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com