Production method for building bamboo plywood

A production method and technology of bamboo plywood, applied in the field of plywood, can solve the problems of low strength and low production efficiency of bamboo plywood, and achieve the effects of easy implementation and mastery, low glue opening rate and high board strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

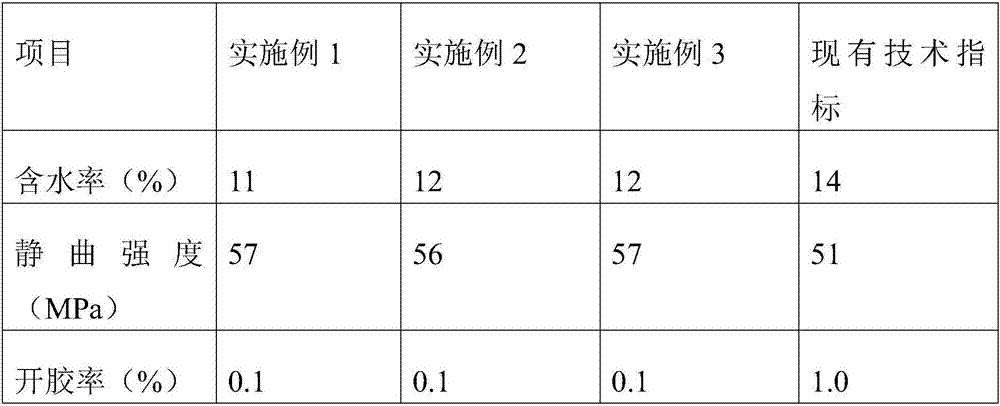

Examples

Embodiment 1

[0020] A kind of production method of bamboo plywood for building, comprises the following steps:

[0021] (1) get fresh bamboo, remove the green bamboo on the surface of the fresh bamboo, then cut the original bamboo into 3-5 pieces, remove the yellow bamboo of the fresh bamboo inner layer and the diaphragm part of the bamboo joint after dissection;

[0022] (2) bamboo chips are pressed by a roller press to make bamboo chips become bamboo fiber bundles, and then dry until the moisture content of bamboo fibers is at 8%;

[0023] (3) Immerse the bamboo fiber bundles in the adhesive glue, take out the redundant adhesive glue on the bamboo fiber surface, the adhesive glue is a phenolic resin adhesive glue, and the dipping amount is 6% of the dry mass of the bamboo fiber bundles. Then the bamboo fiber bundles are dried at a temperature of 50-60°C until the moisture content is 8%.

[0024] (4) Bamboo fiber veneers and wood veneers are stacked to form embryos, the upper and lower l...

Embodiment 2

[0028] A kind of production method of bamboo plywood for building, comprises the following steps:

[0029] (1) get fresh bamboo, remove the green bamboo on the surface of the fresh bamboo, then cut the original bamboo into 3-5 pieces, remove the yellow bamboo of the fresh bamboo inner layer and the diaphragm part of the bamboo joint after dissection;

[0030] (2) bamboo chips are squeezed by a roller press to make bamboo chips become bamboo fiber bundles, and then dry until the moisture content of bamboo fibers is 10%;

[0031] (3) Immerse the bamboo fiber bundles in the adhesive glue, take out the redundant adhesive glue on the surface of the bamboo fibers, the adhesive glue is a phenolic resin adhesive glue, and the dipping amount is 5% of the dry mass of the bamboo fiber bundles. Then the bamboo fiber bundles are dried at a temperature of 50-60°C until the moisture content is 10%.

[0032] (4) Bamboo fiber veneers and wood veneers are stacked to form embryos, the upper and...

Embodiment 3

[0036] A kind of production method of bamboo plywood for building, comprises the following steps:

[0037] (1) get fresh bamboo, remove the green bamboo on the surface of the fresh bamboo, then cut the original bamboo into 3-5 pieces, remove the yellow bamboo of the fresh bamboo inner layer and the diaphragm part of the bamboo joint after dissection;

[0038] (2) bamboo chips are squeezed by a roller press to make bamboo chips become bamboo fiber bundles, and then dry until the moisture content of bamboo fibers is 10%;

[0039] (3) Immerse the bamboo fiber bundles in the adhesive glue, take out the excess adhesive glue on the surface of the bamboo fibers, the adhesive glue is a phenolic resin adhesive glue, and the dipping amount is 7% of the dry mass of the bamboo fiber bundles. Then the bamboo fiber bundles are dried at a temperature of 50-60°C until the moisture content is 10%.

[0040] (4) Bamboo fiber veneers and wood veneers are stacked to form embryos, the upper and lo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap