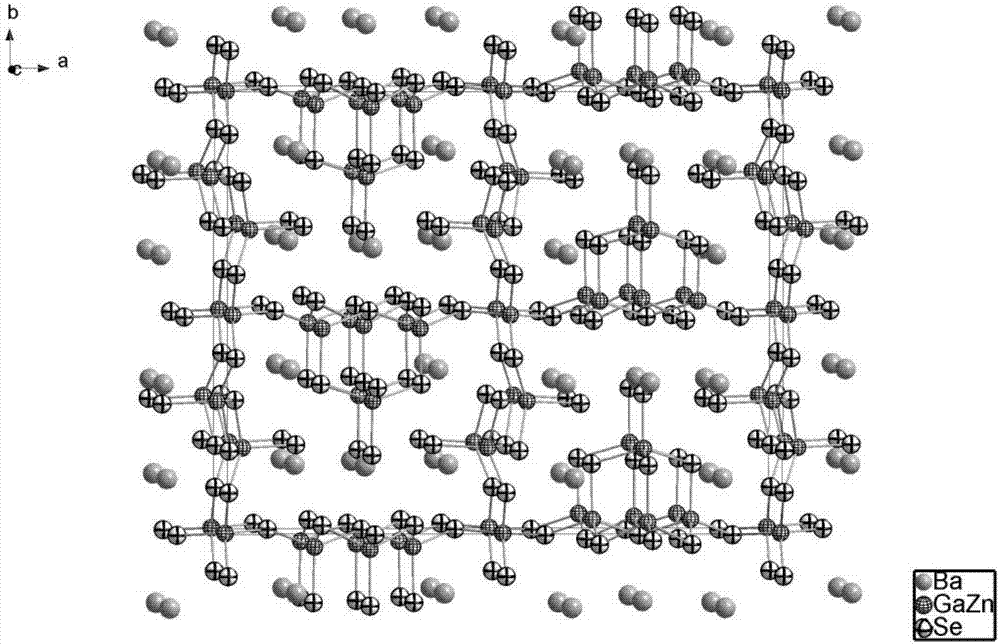

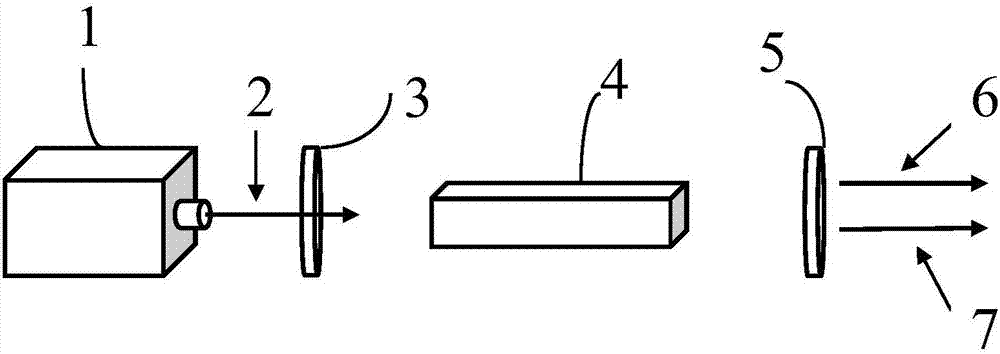

Selenium gallium zinc barium compound, selenium gallium zinc barium infrared nonlinear optical crystal, and preparation methods and purposes thereof

A compound, zinc-barium technology, applied in the field of inorganic compound materials, achieves the effects of fast growth, low cost, easy processing and preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Using 5BaSe+ZnGa 2 Se 4 +2Ga 2 Se 3 = Ba 5 ZnGa 6 Se 15 The reaction formula uses a high-temperature solid-state reaction method to prepare selenium-gallium-zinc-barium compounds;

[0037] The BaSe is 10.815 g, the ZnGa 2 Se 4 5.207 g, the Ga 2 Se 3 It is 7.527 grams; namely BaSe:ZnGa 2 Se 4 : Ga 2 Se 3 =0.05mol:0.01mol:0.02mol;

[0038] The specific operation steps are: weigh the reagents according to the above dosage in the glove box, put them into a mortar, mix and grind them, then put them into a Φ19mm×25mm quartz tube, and evacuate them to 10 -3 After Pa, the quartz tube was melted and packaged with an oxyhydrogen flame, put into a muffle furnace, raised to 800°C at a rate of 50°C / h, and kept at a temperature of 96h. After cooling, the sample was taken out, and the sample was ground and mixed before placing it again Vacuum the quartz tube to 10 -3 Pa was melted and sealed, and then put into a muffle furnace and heated to 800°C for sintering for 48 h...

Embodiment 2

[0040] Using 5BaSe+ZnGa 2 Se 4 +4Ga+6Se=Ba 5 ZnGa 6 Se 15 The reaction formula uses a high-temperature solid-state reaction method to prepare selenium-gallium-zinc-barium compounds;

[0041] The BaSe is 10.815 g, the ZnGa 2 Se 4 Be 5.207 grams, described Ga is 2.789 grams, and described Se is 4.738 grams; Namely BaSe:ZnGa 2 Se 4 :Ga:Se=0.05mol:0.01mol:0.04mol:0.06mol;

[0042] The specific operation steps are to weigh the reagents in the glove box according to the above dosage, mix them, and then put them into a quartz tube of Φ19mm×25mm, and vacuumize to 10 -3 After Pa, the quartz tube was melted and packaged with a hydrogen-oxygen flame, put into a muffle furnace, raised to 900°C at a rate of 30°C / h, and kept at a temperature of 96h. After cooling, the sample was taken out, and the sample was ground and mixed before being placed again. Vacuum the quartz tube to 10 -3 Pa was melted and sealed, and then put into a muffle furnace and heated to 800°C for sintering for ...

Embodiment 3

[0044] Using 5Ba+ZnGa 2 Se 4 +2Ga 2 Se 3 +5Se=Ba 5 ZnGa 6 Se 15 The reaction formula uses a high-temperature solid-state reaction method to prepare selenium-gallium-zinc-barium compounds;

[0045] The Ba is 6.866 g, the ZnGa 2 Se 4 5.207 g, the Ga 2 Se 3 7.527 grams, the Se is 3.948 grams; namely BaSe:ZnGa 2 Se 4 : Ga 2 Se 3 : Se=0.05mol:0.01mol:0.02mol:0.05mol;

[0046] The specific operation steps are to weigh the reagents in the glove box according to the above doses, put them into a Φ19mm×25mm quartz tube, and evacuate to 10 -3 After Pa, the quartz tube was melted and packaged with a flame, put into a muffle furnace, and slowly raised to 850°C, the heating rate was 40°C / h, and kept for 96h. Vacuum the quartz tube to 10 -3 Pa was melted and sealed, and then put into a muffle furnace and heated to 800°C for sintering for 48 hours; the sample was taken out and ground to obtain powdered Ba 5 ZnGa 6 Se 15 compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com