Cultivation method for improving polysaccharide content of phellinus igniarius

A technology of polysaccharide content and cultivation method, which is applied in cultivation, plant cultivation, mushroom cultivation, etc., can solve the problems of low polysaccharide content, low economic value, and low cultivation utilization rate of Phellinus japonica, and achieve high economic value of Phellinus japonica, shortening the The effect of high cultivation time and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

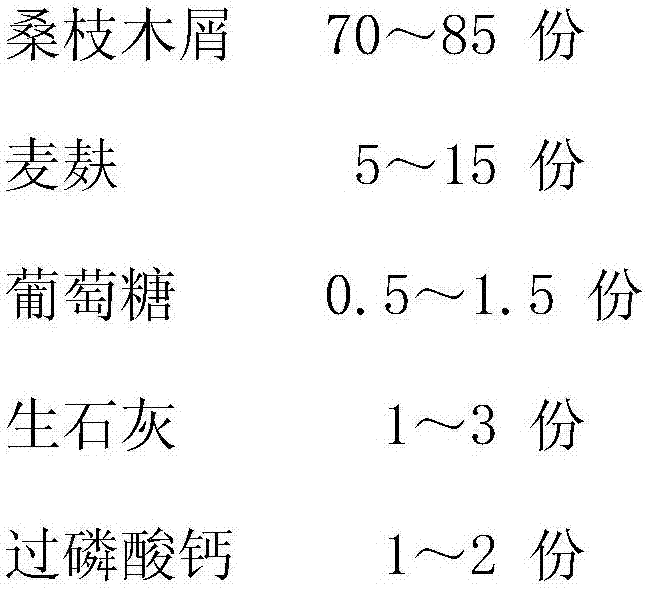

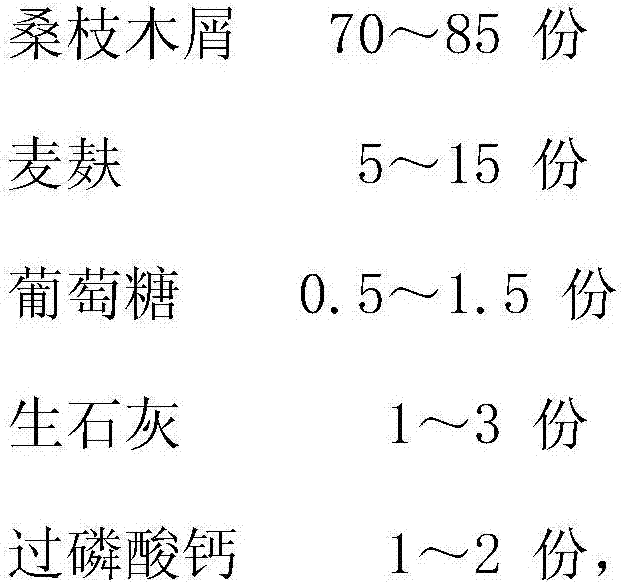

[0030] Embodiment 1 discloses a cultivation method for increasing the Phellinus polysaccharide content, including base material preparation, bagging, high temperature sterilization, inoculation, hyphae culture, fruiting management and picking steps,

[0031] Base material preparation: accurately weigh the main and auxiliary materials according to the formula ratio, stir evenly, add water in an appropriate amount to achieve a suitable material-water ratio, and then carry out the bagging step; In the film tube, seal it to make cultivated mushroom sticks; high-temperature sterilization: put the Phellinus cultivated sticks in the sterilization room for sterilization, the sterilization temperature reaches 100°C, keep for 10-12 hours, cool down after sterilization, transfer Enter the inoculation process; inoculation: when the temperature of the bacterial sticks is naturally cooled to below 28°C, the inoculation can be done. The bacterial sticks should be inoculated while punching hol...

Embodiment 2

[0035] Embodiment 2 has the same operation steps as in Example 1, the difference is that in Example 2, a biological growth regulator is added in the base material preparation and inoculation process, and the biological growth regulator is composed of oleic acid and α-naphthaleneacetic acid, and the base material In the preparation step, the components (weight) of the base material are: 83 parts of mulberry wood chips; 12 parts of bran; 1 part of glucose, 2 parts of quicklime, 1.5 parts of superphosphate, and a water content of 60-65%. At the same time, 0.2 part of oleic acid is added to the base material. Before the inoculation step begins after the high-temperature sterilization step is finished, the component content of 0.03 part of α-naphthaleneacetic acid will be injected at the inoculation port, and then the inoculation step is carried out. The depth of growth regulator injection is 2 / 3 of the thickness of the bacteria stick. The content of polysaccharides in the fruiting...

Embodiment 3

[0037] Embodiment 3 takes the same cultivation steps as in Example 1. The difference is that in the present embodiment, in the matrix material preparation and mycelia cultivation steps, a biological growth regulator is added, and the biological growth regulator is composed of oleic acid and 3- Indole butyric acid; in the base material preparation step, the component (weight) of base material is: 85 parts of mulberry wood chips; 12 parts of bran; 1.5 parts of glucose, 1.5 parts of quicklime, 1 part of superphosphate, and the water content is 60-65%. At the same time, 0.05 part of oleic acid was added to the base material; after the main material and auxiliary materials were accurately weighed according to the proportion of the formula, they were repeatedly stirred evenly, and then the bagging step was carried out; When the bacteria sticks are punctured, 0.03 parts of α-naphthaleneacetic acid is injected into the bacteria sticks, and the injection depth of the biological growth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com