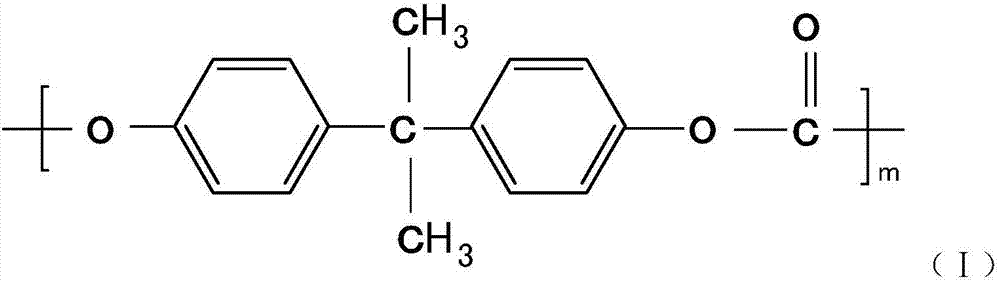

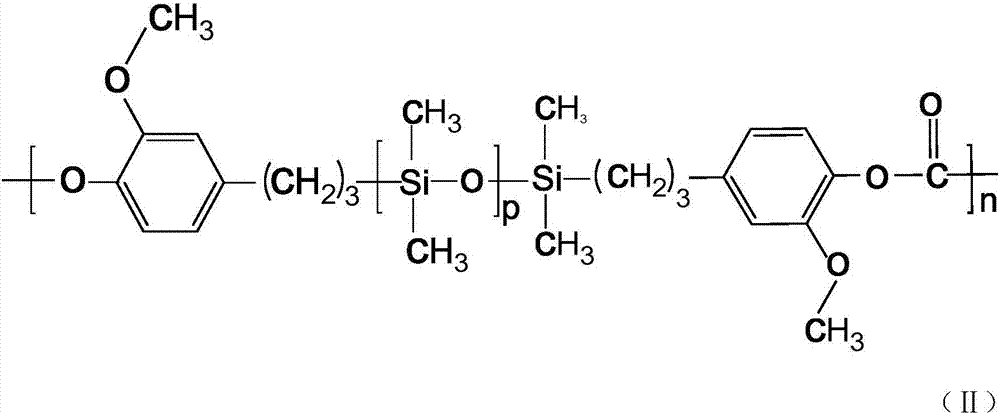

Polysiloxane block specific end-capped copolycarbonate and preparation method thereof

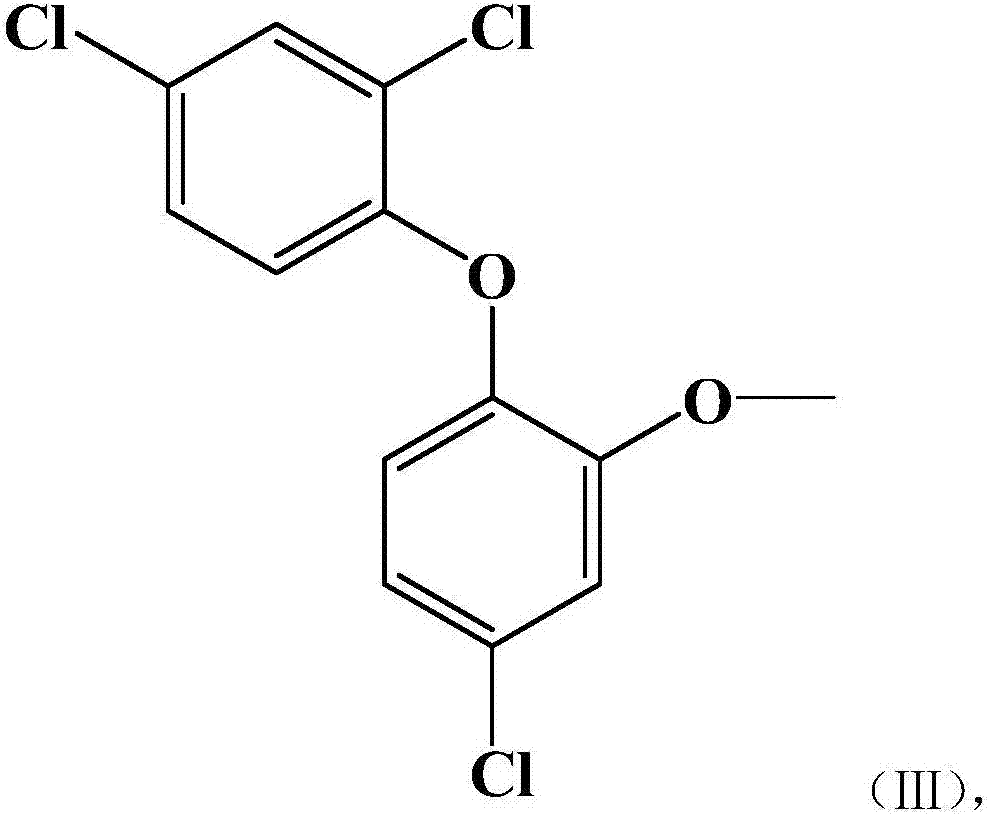

A technology of polysiloxane block and copolycarbonate is applied in the field of preparing the specific end-capped copolycarbonate, which can solve the problem of low mechanical properties of antibacterial polycarbonate plastics, no real antibacterial effect, polycarbonate The effect of promoting large-scale application, excellent mechanical properties, and simple and easy preparation method is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0048] Add 228.3kg of bisphenol A, 100kg of sodium hydroxide, and 1600kg of water into the mixer and mix them. After bisphenol A is completely dissolved, add 324g of catalyst tetrabutylammonium bromide and stir until it is completely dissolved. Then add 2.4kg of tributylammonium bromide. Add 128.9kg of liquid phosgene and 4851L of dichloromethane to another mixer and mix evenly to form an oil phase; then put the sodium phenate salt phase into the polymerization reactor, and then The oil phase and 26.4kg of eugenol-terminated polysiloxane prepared in the preliminary examples were added to the polymerization reactor at a rate of 100g / min and 150g / min respectively under the stirring speed of 10% by weight of sodium hydroxide aqueous solution keeps the pH value of the reaction system at 10.5, and the temperature of the reaction system is maintained at 45° C.; after 2 hours of reaction, the reaction system is separated and purified and the organic solvent is removed to obtain the ra...

preparation Embodiment 2

[0050] Add 228.3kg of bisphenol A, 129kg of sodium hydroxide, and 1900kg of water into the mixer and mix them. After bisphenol A is completely dissolved, add 365g of catalyst tetrabutylammonium bromide and stir until it is completely dissolved. Then add 3.9kg of tributylammonium bromide. Chlorogene and stir evenly to form a water phase; add 130.5kg liquid phosgene and 5417L dichloromethane to another mixer, mix evenly to form an oil phase; The oil phase and 39.5kg of eugenol-terminated polysiloxane prepared in the preliminary examples were added to the polymerization reactor at a rate of 120g / min and 170g / min respectively under the stirring speed of 10% by weight of sodium hydroxide aqueous solution keeps the pH value of the reaction system at 10.9, and the temperature of the reaction system is maintained at 47° C.; after 2.5 hours of reaction, the reaction system is separated and purified and the organic solvent is removed to obtain the random copolymer of the present inventio...

preparation Embodiment 3

[0052] Add 228.3kg of bisphenol A, 145kg of sodium hydroxide, and 2100kg of water into the mixer and mix them. After bisphenol A is completely dissolved, add 400g of catalyst tetrabutylammonium bromide and stir until it is completely dissolved. Then add 3.9kg of tributylammonium bromide. Chlorogene and stir evenly to form a water phase; add 135.1kg liquid phosgene and 6118L dichloromethane to another mixer, mix evenly to form an oil phase; The oil phase and 51.2kg of eugenol-terminated polysiloxane prepared in the preliminary examples were added to the polymerization reactor at a rate of 150g / min and 180g / min respectively under the stirring speed of 10% by weight of sodium hydroxide aqueous solution keeps the pH value of the reaction system at 11.2, and the temperature of the reaction system is maintained at 50° C.; after 2.5 hours of reaction, the reaction system is separated and purified and the organic solvent is removed to obtain the random copolymer of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com