Preparation method for high-conductivity nanometer silver-coated copper thick film paste capable of being sintered in air

A high-conductivity, nano-silver technology, applied in conductive materials, conductive materials, conductive materials and other directions dispersed in non-conductive inorganic materials, can solve the problems of low conductivity, reduced conductivity, and reduced conductivity, and achieves The effect of good electromigration resistance, increased electrical conductivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

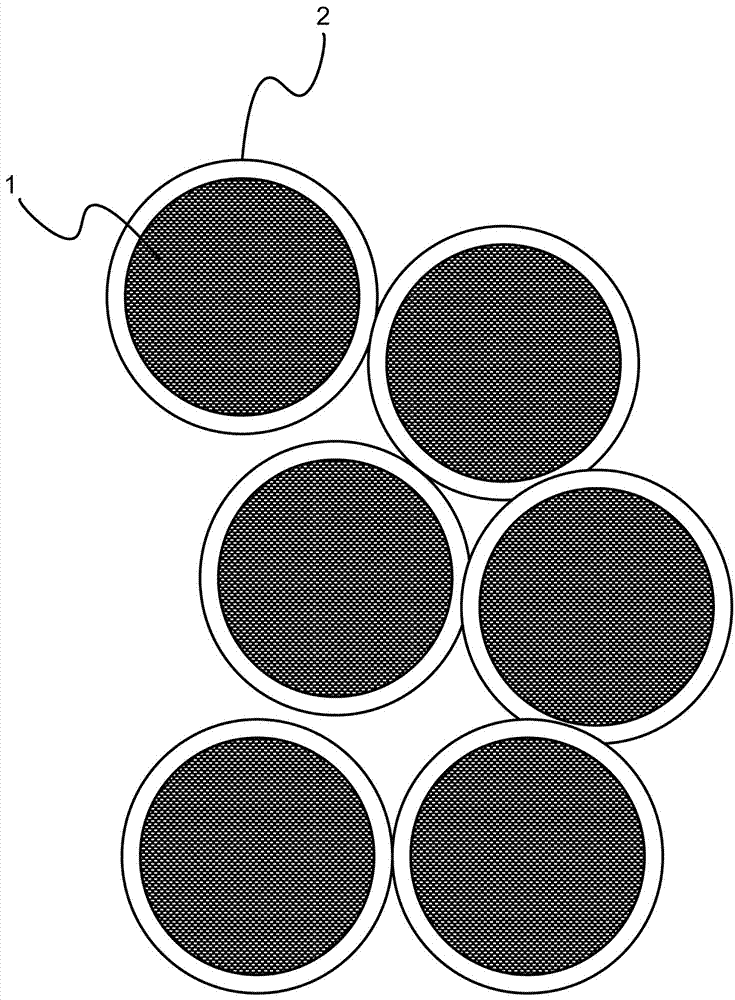

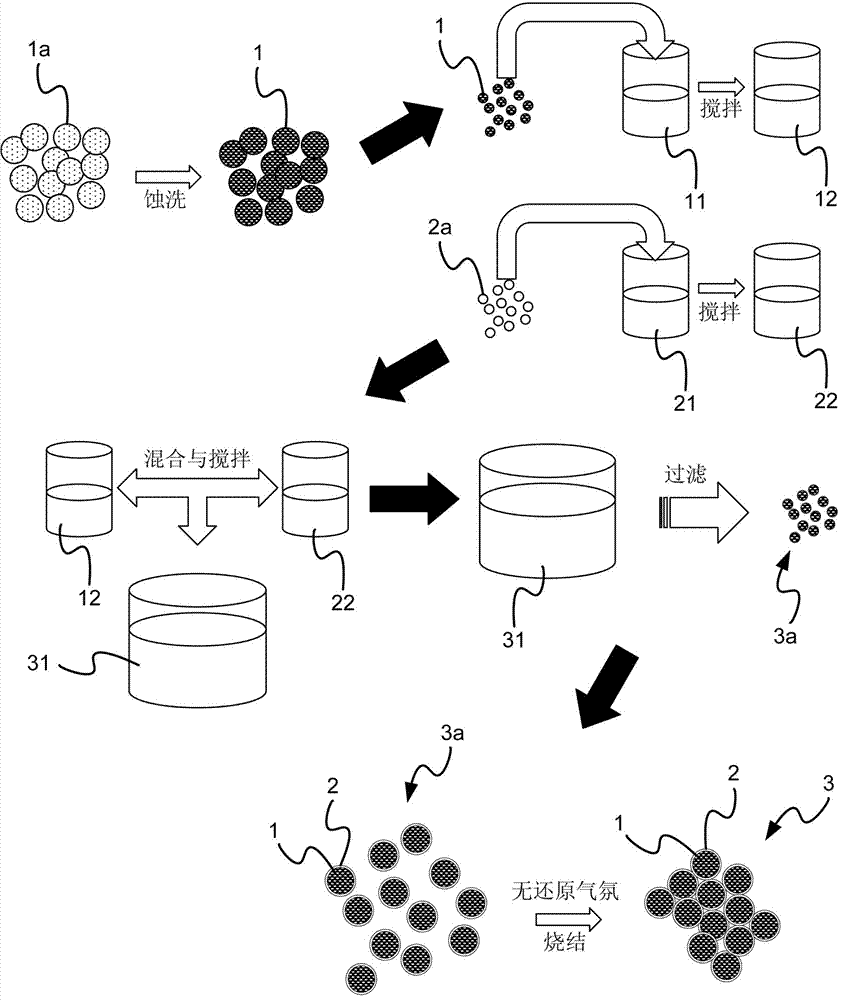

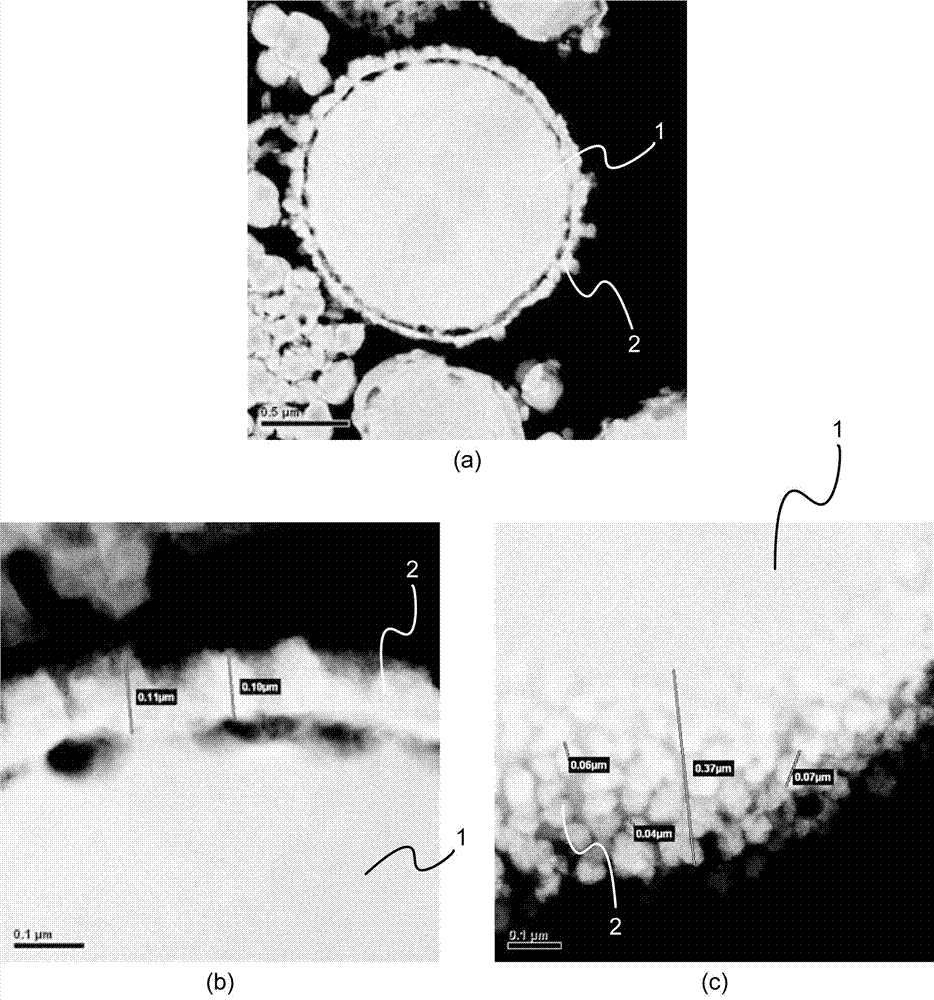

[0038] see Figure 1 to Figure 5 Shown are the schematic diagram of the structure of the nano-silver-coated copper thick film paste of the present invention, the schematic diagram of the production process of the nano-silver-coated copper powder of the present invention, the SEM image of the surface of the nano-silver-coated metal copper powder of the present invention, and the sintered nano-silver coating of the present invention at different temperatures. The SEM image of metal copper, and the schematic diagram of measuring the efficiency of nano-silver-coated metal copper applied to the positive electrode of a solar cell according to the present invention. As shown in the figure: the present invention is a preparation method for sintering high-conductivity nano-silver-coated copper thick film paste in the air. It is a layer of nano-silver 2 on the surface of metal copper particles or copper powder 1, so that the nano-silver 2 encase metal copper particles or copper powder 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com