MnO doped ferroferric oxide/C graded nanosphere structure composite material and preparation method thereof

A composite material and nanosphere technology, which is applied in the directions of iron oxide/iron hydroxide, ferrous oxide, manganese oxide/manganese hydroxide, etc., can solve the problems of complicated operation and complicated steps, and achieve a short synthesis period, Low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

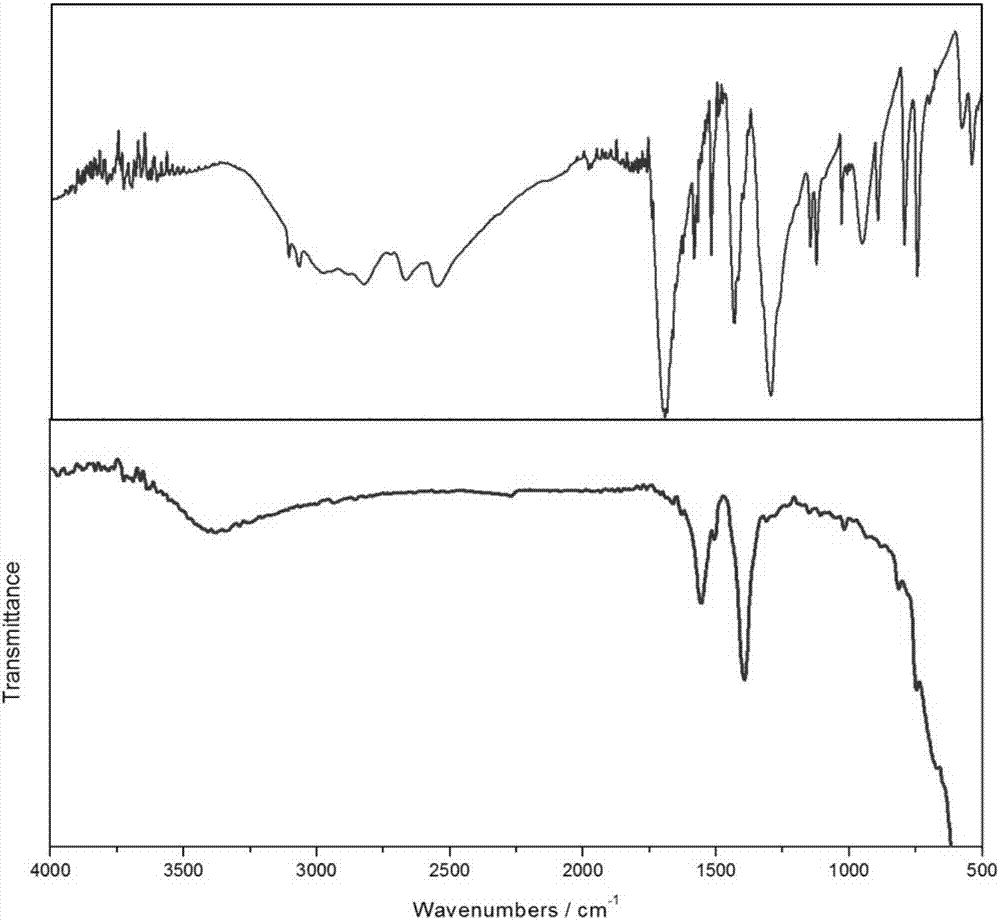

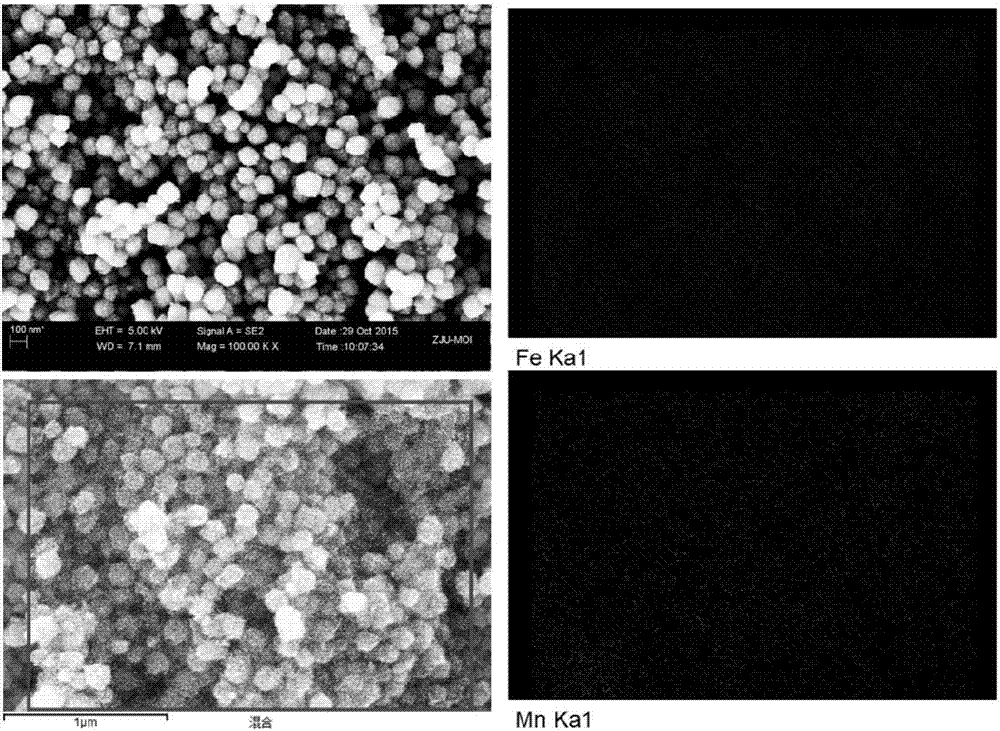

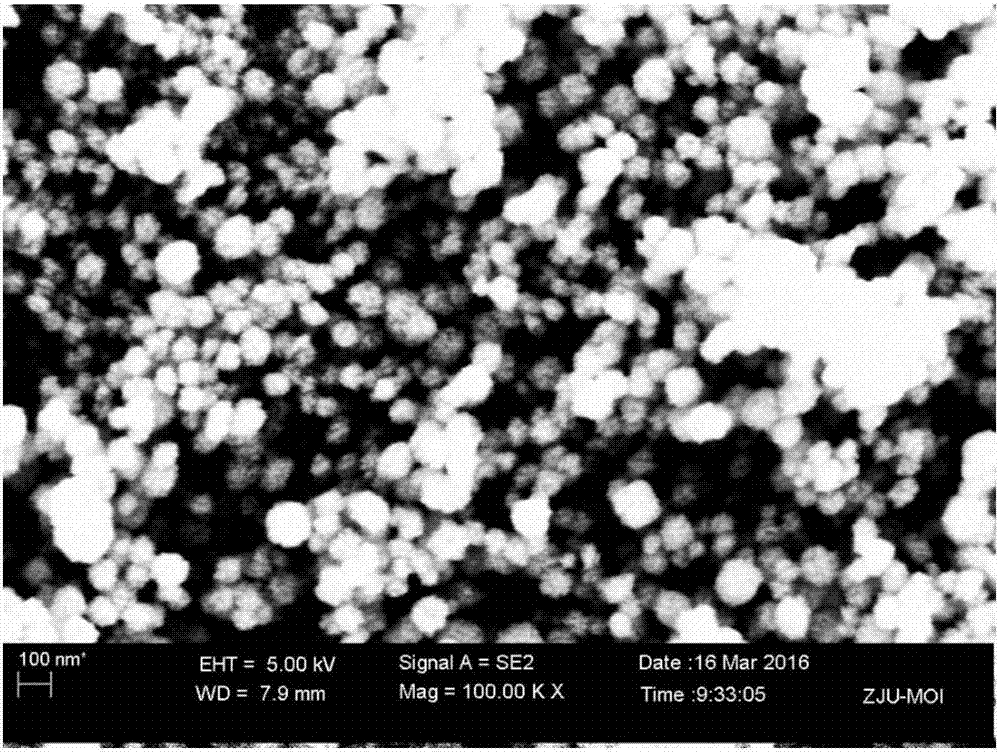

[0030] A preparation of MnO-doped Fe from ferric nitrate, manganese acetate, terephthalic acid and urea 3 o 4 The steps of @C hierarchical nanosphere structure composite material are as follows:

[0031] (1) Weigh 2 mmol of ferric nitrate, 1 mmol of manganese acetate, 3 mmol of terephthalic acid, and 5 mmol of urea, respectively.

[0032] (2) Each reaction raw material that weighs is joined in the small beaker, adds DMF 40mL, H 2 O 10mL, sonicate for 30min to disperse and dissolve each substance in the mixed solvent to form a cloudy reaction solution.

[0033] (3) Transfer the reaction turbid liquid into a stainless steel reaction kettle with Teflon lining, and react in a high-temperature oven at 150° C. for 3 hours.

[0034] (4) After the reaction, the reactor was naturally cooled to room temperature, and the obtained tan powder was washed several times with deionized water and absolute ethanol, and then dried at 60° C. overnight.

[0035] (5) Under an argon atmosphere, t...

Embodiment 2

[0037] A preparation of MnO-doped Fe from ferric nitrate, manganese sulfate, terephthalic acid and urea 3 o 4 The steps of @C hierarchical nanosphere structure composite material are as follows:

[0038] (1) Weigh 2 mmol of ferric nitrate, 1 mmol of manganese sulfate, 3 mmol of terephthalic acid, and 5 mmol of urea, respectively.

[0039] (2) Each reaction raw material that weighs is joined in the small beaker, adds DMF 40mL, H 2 O 10mL, sonicate for 30min to disperse and dissolve each substance in the mixed solvent to form a cloudy reaction solution.

[0040] (3) Transfer the reaction turbid liquid into a stainless steel reaction kettle with Teflon lining, and react in a high-temperature oven at 180° C. for 2 hours.

[0041] (4) After the reaction, the reactor was naturally cooled to room temperature, and the obtained tan powder was washed several times with deionized water and absolute ethanol, and then dried at 60° C. overnight.

[0042] (5) Under an argon atmosphere, t...

Embodiment 3

[0044] A preparation of MnO-doped Fe from ferric nitrate, manganous chloride, terephthalic acid and urea 3 o 4 The steps of @C hierarchical nanosphere structure composite material are as follows:

[0045] (1) Weigh 2 mmol of ferric nitrate, 1 mmol of manganous chloride, 3 mmol of terephthalic acid, and 5 mmol of urea, respectively.

[0046] (2) Each reaction raw material that weighs is joined in the small beaker, adds DMF 40mL, H 2 O 10mL, ultrasonic for 30min to disperse and dissolve each substance in the mixed solvent to form a reaction turbid solution.

[0047] (3) Transfer the reaction turbid liquid into a stainless steel reaction kettle with Teflon lining, and react in a high-temperature oven at 150° C. for 3 hours.

[0048] (4) After the reaction, the reactor was naturally cooled to room temperature, and the obtained tan powder was washed several times with deionized water and absolute ethanol, and then dried at 60° C. overnight.

[0049] (5) Under an argon atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com