Zirconium-oxide ceramic, mobile phone backboard, preparing method of zirconia ceramic and preparing method of mobile phone backboard

A technology of zirconia ceramics and zirconia, which is applied in the field of ceramic materials and can solve problems such as poor wear resistance, poor wear resistance, and singleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

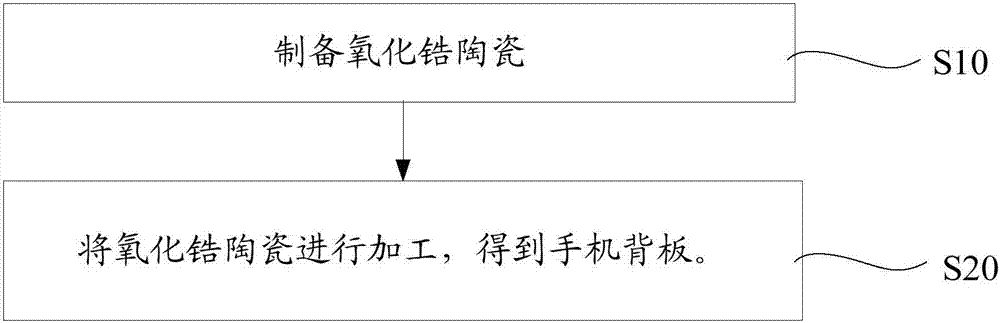

[0029] Such as figure 1 Shown, the preparation method of the mobile phone back plate of an embodiment, comprises the following steps:

[0030] Step S10: preparing zirconia ceramics.

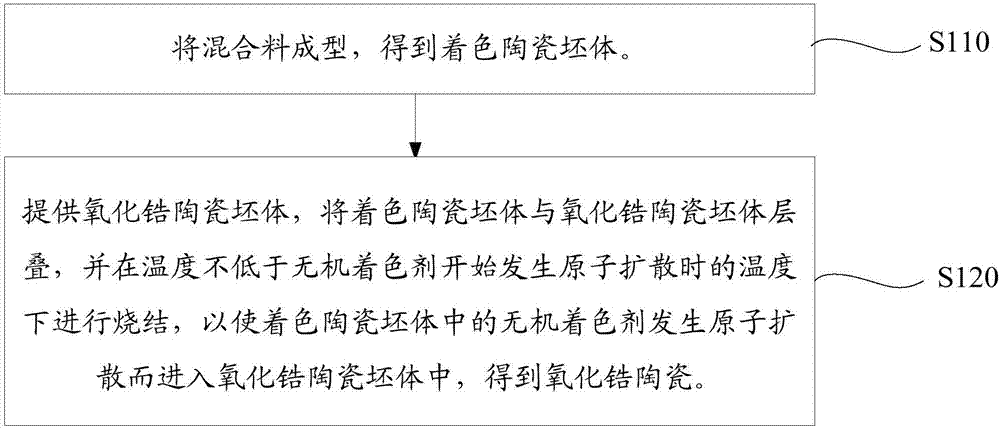

[0031] Please also refer to figure 2 , wherein, the preparation method of zirconia ceramics comprises the following steps:

[0032] Step S110: molding the mixture to obtain a colored ceramic green body.

[0033] Wherein, the mixture includes zirconium oxide and inorganic colorant in a mass ratio of 80-90:10-20. The mixture of zirconia and inorganic colorants in this mass ratio can ensure the molding of the colored ceramic body and have sufficient strength; and zirconia is used as the ceramic powder in the mixture, so that during sintering, the colored ceramic body and zirconia There will be no reaction between the ceramic bodies, but other ceramic powders will react with the zirconia ceramic bodies to form eutectic compounds, which will affect the strength and appearance of the sintered zirc...

Embodiment 1

[0067] The preparation process of the mobile phone backboard of the present embodiment is as follows:

[0068] (1) Add zirconia, inorganic colorant, sintering aid and water into a ball mill tank and mix them for 5 hours on a planetary ball mill. The speed of ball milling is 250 rpm to obtain a slurry. The mass ratio of the additive is 85:15, and the inorganic colorant is cobalt oxide; the mass ratio of the sintering aid to zirconia is 0.9:190, and the sintering aid is composed of alumina, lithium carbonate and boron oxide, and alumina, lithium carbonate And the mass ratio of boron oxide is 7:1.5:1.5, the mass ratio of the sum of the mass of zirconia, inorganic colorant and sintering aid to the ball milling medium is 1:2, the mass ratio of zirconia, inorganic colorant and sintering aid The mass ratio of the sum to water is 1:0.6; then the slurry is filtered through a 30-mesh sieve, and placed on a stainless steel plate to dry at 190°C for 2.5 hours, and then add polyvinyl alcoh...

Embodiment 2

[0077] The preparation process of the mobile phone backboard of the present embodiment is as follows:

[0078](1) Add zirconia, inorganic colorant, sintering aid and water into a ball mill tank and mix them for 4 hours on a planetary ball mill at a speed of 200 rpm to obtain a slurry, wherein zirconia and inorganic coloring The mass ratio of agent is 80:20, and inorganic colorant is tin oxide, calcium carbonate, dichromium oxide and erbium oxide, and the mass ratio of tin oxide, calcium carbonate, dichromium oxide and erbium oxide is 5:0.6:0.2: 0.4; the mass ratio of sintering aid to zirconia is 0.8:180, the sintering aid is composed of alumina, lithium carbonate and boron oxide, and the mass ratio of alumina, lithium carbonate and boron oxide is 8:1:1, and the mass ratio of sintering aid is 8:1:1. The sum of the mass of zirconium, inorganic colorant and sintering aid is 1:1.5 with the mass ratio of ball milling medium, and the mass ratio of zirconia, inorganic colorant and si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com