Nitric acid reduction method used in methyl nitrite preparation process

A technology for the preparation process of methyl nitrite, applied in the field of preparation of dimethyl oxalate, can solve the problems of waste of raw materials, environmental pollution, etc., and achieve the effects of reducing equipment corrosion, being environmentally friendly, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be further described below in conjunction with embodiments.

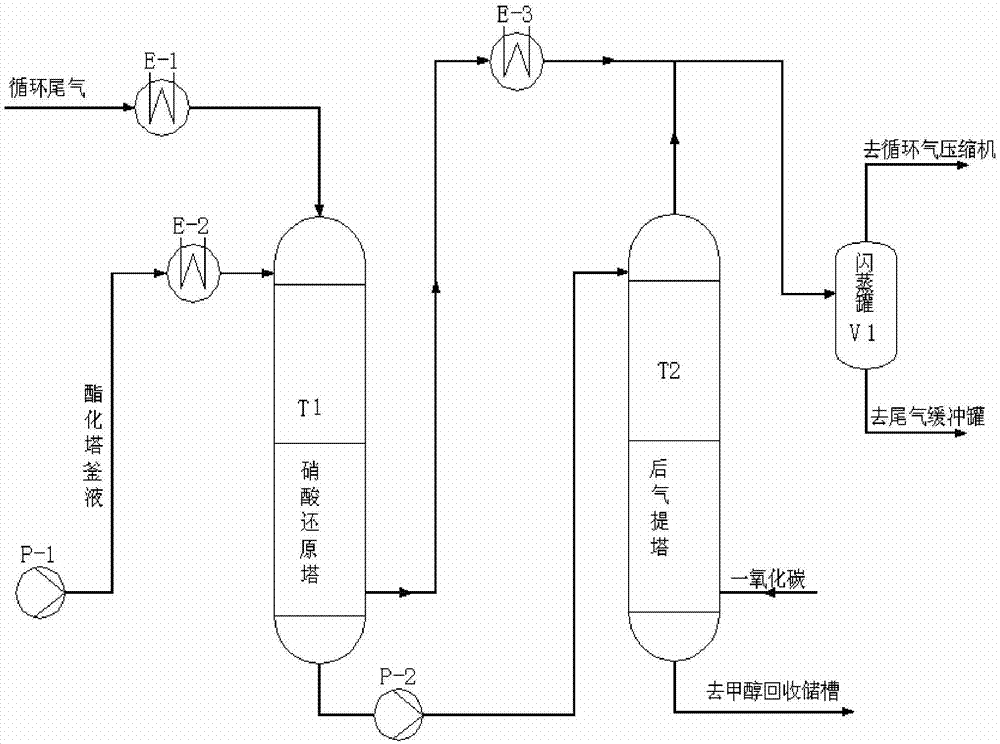

[0017] The methyl nitrite of the present invention is prepared by the esterification reaction of methanol, nitric oxide and oxygen. During the reaction process, part of the nitric oxide undergoes side reactions to generate nitric acid, which is dissolved in the methanol liquid for the reaction. Methanol will circulate and accumulate and corrode equipment. The invention can realize the reuse of by-product nitric acid and convert it into methyl nitrite product. The principle is to add a nitric acid reduction tower and a gas stripping tower, and the preheated methanol solution with nitric acid dissolved in the nitrogen monoxide cycle gas is reduced to methyl nitrite in the nitric acid reduction tower, and then the carbon monoxide is used in the gas stripping tower. Propose methyl nitrite.

[0018] Such as figure 1 As shown, the nitric acid gas by-produced in the liquid phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com