Epoxy molding plastics for manufacturing light reflection components and method for preparing epoxy molding plastics

An epoxy molding compound, light reflection technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of high water absorption, high epoxy value, high hydroxyl content of cured products, high fluidity, high temperature yellow resistance The effect of strong variable ability and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

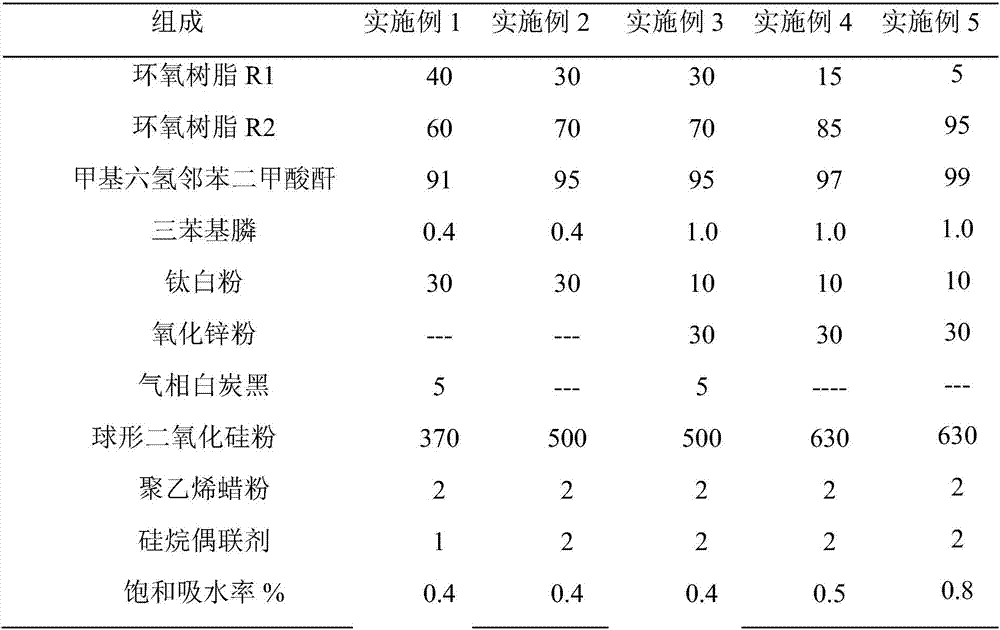

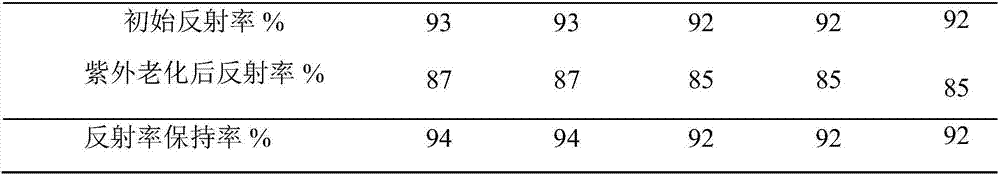

Embodiment 1

[0041] (1) Take 60 parts by mass of alicyclic epoxy resin R2 and heat to 90°C, add 40 parts by mass of alicyclic epoxy resin R1, and stir slowly until the alicyclic epoxy resin R1 is completely dissolved to make resin R2 / resin R1 is 60 / 40 liquid mixed cycloaliphatic epoxy resin;

[0042] (2) Take 91 parts by mass of methylhexahydrophthalic anhydride, add 0.5 parts by mass of triphenylphosphine and 2 parts by mass of silane coupling agent, and stir until the triphenylphosphine is dissolved;

[0043] (3) Inject the mixed liquid epoxy resin and methylhexahydrophthalic anhydride into the vacuum mixer in turn, slowly add 30 parts by mass of titanium dioxide, 5 parts by mass of fumed white carbon black and 2 parts by mass of polyethylene wax powder at 50°C , And control the temperature not to exceed 70℃, stir for 10 minutes, slowly add 250 parts by mass of spherical silica powder, stir until the silica powder is infiltrated by the resin, then add 120 parts by mass of spherical silica pow...

Embodiment 2

[0048] (1) Take 70 parts by mass of alicyclic epoxy resin R2 and heat to 90°C, add 30 parts by mass of alicyclic epoxy resin R1, and stir slowly until the alicyclic epoxy resin R1 is completely dissolved to make resin R2 / resin R1 is 70 / 30 liquid mixed cycloaliphatic epoxy resin;

[0049] (2) Take 95 parts by mass of methylhexahydrophthalic anhydride, add 0.5 parts by mass of triphenylphosphine and 2 parts by mass of silane coupling agent, and stir until the triphenylphosphine is dissolved;

[0050] (3) Inject the liquid mixed epoxy resin and methylhexahydrophthalic anhydride into the vacuum mixer in turn, slowly add 30 parts by mass of titanium dioxide white pigment and 2 parts by mass of polyethylene wax powder at 50°C, and control the temperature not to exceed 70℃, stir for 10 minutes, slowly add 300 parts by mass of spherical silica powder, stir until the silica powder is infiltrated by the resin, then add 200 parts by mass of spherical silica powder, and stir until the silica p...

Embodiment 3

[0055] (1) Take 70 parts by mass of alicyclic epoxy resin R2 and heat to 90°C, add 30 parts by mass of alicyclic epoxy resin R1, and stir slowly until the alicyclic epoxy resin R1 is completely dissolved to make resin R2 / resin R1 is 70 / 30 liquid mixed cycloaliphatic epoxy resin;

[0056] (2) Take 95 parts by mass of methylhexahydrophthalic anhydride, add 1 part by mass of triphenylphosphine and 2 parts by mass of silane coupling agent, and stir until the triphenylphosphine is dissolved;

[0057] (3) Inject the liquid mixed epoxy resin and methylhexahydrophthalic anhydride into the vacuum mixer in turn, slowly add 10 parts by mass of titanium dioxide, 30 parts by mass of zinc oxide powder, 5 parts by mass of fumed silica, at 50°C. 2 parts by mass of polyethylene wax powder, control the temperature not to exceed 70°C, stir for 15 minutes, slowly add 300 parts by mass of spherical silica powder, stir until the silica powder is infiltrated by the resin, and then add 200 parts by mass o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com