Isocyanate-free primer and preparation method and application thereof

A technology free of isocyanates and isocyanates, applied in polyurea/polyurethane coatings, coatings, primers, etc., can solve the problems of long duration, high inhalation toxicity, and low oral toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides a kind of preparation method of the isocyanate-free primer described in the above technical scheme, comprising the following steps:

[0043] Mix polyol polymer with isocyanate and react to obtain isocyanate-terminated polymer;

[0044] The isocyanate-terminated polymer is mixed with a solvent, a color paste, an adhesion promoter, and a catalyst to obtain an isocyanate-free primer.

[0045] The invention mixes the polyol polymer and the isocyanate to react to obtain the isocyanate-terminated polymer. In the present invention, the types and sources of the polyol polymer and isocyanate are the same as those of the polyol polymer and isocyanate described in the above technical solution, and will not be repeated here. In the present invention, the reaction temperature is preferably 60-80° C., more preferably 70° C.; the reaction time is preferably 1-3 hours, more preferably 2 hours.

[0046] After the isocyanate-terminated polymer is obtained...

Embodiment 1

[0055] Add 120g of polyoxypropylene trihydric alcohol (average molecular weight 4800g / mol) into the reactor with mechanical stirring, vacuum, nitrogen protection and heating device, stir at 90°C, and vacuum dry for 3h; then cool down to 70°C, add 18.75 g diphenylmethane diisocyanate, N Under the atmosphere, react for 2h to obtain the isocyanate-terminated polymer, and the R value of the isocyanate-terminated polymer is 2.0;

[0056] Under N2 atmosphere, gradually disperse 10g of the above-mentioned isocyanate-terminated polymer, 65g of ethyl acetate, 15g of color paste, and stir at room temperature for 30min; then add 10g of bis-(γ-trimethoxysilylpropyl)amine, 0.1g of titanic acid n-Butyl ester and 0.1 g of bis(2-dimethylaminoethyl) ether were stirred and dispersed at room temperature for 30 minutes to obtain an isocyanate-free primer.

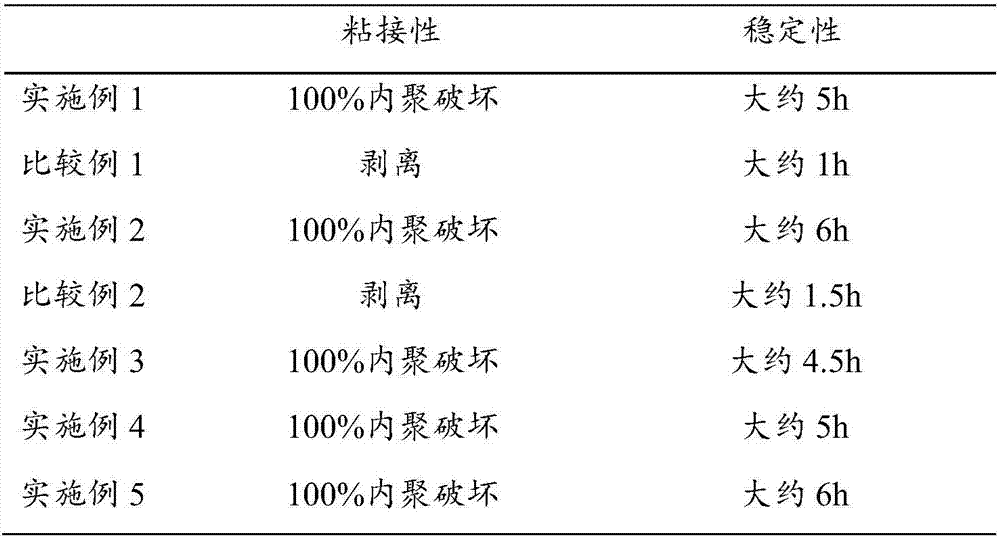

[0057] The present invention tests the adhesion and stability of the primer prepared in Example 1 according to the bonding effect test method...

Embodiment 2

[0065] Add 120g of polyester polyol (ethylene glycol adipic acid polymerization) (average molecular weight 2000g / mol) into a reactor equipped with mechanical stirring, vacuum, nitrogen protection and heating device, stir at 90°C, and dry in vacuum for 3h; then Cool down to 70°C, add 17.4g of toluene diisocyanate, and react under N2 atmosphere for 2 hours to obtain an isocyanate-terminated polymer, the R value of which is 1.67;

[0066] Under N2 atmosphere, gradually disperse 10g of the above-mentioned isocyanate-terminated polymer, 65g of ethyl acetate, 15g of color paste, stirring and dispersing at room temperature for 30min; then add 8g of bis-(γ-trimethoxysilylpropyl)amine, 4g of N-β -(Aminoethyl)-γ-aminopropyltrimethoxysilane, 0.1g bismuth isooctanoate and 0.1g bis(2-dimethylaminoethyl)ether, continue to stir and disperse at room temperature for 30min, and obtain an isocyanate-free primer agent.

[0067] The present invention tests the adhesion and stability of the primer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com