A kind of composite absorbing agent, preparation method and application thereof

A wave-absorbing agent and reaction product technology, applied in the field of wave-absorbing materials, can solve problems such as difficult to achieve impedance matching, poor electromagnetic wave absorption, low dielectric constant, etc., and achieve the effects of easy promotion, high detection efficiency, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

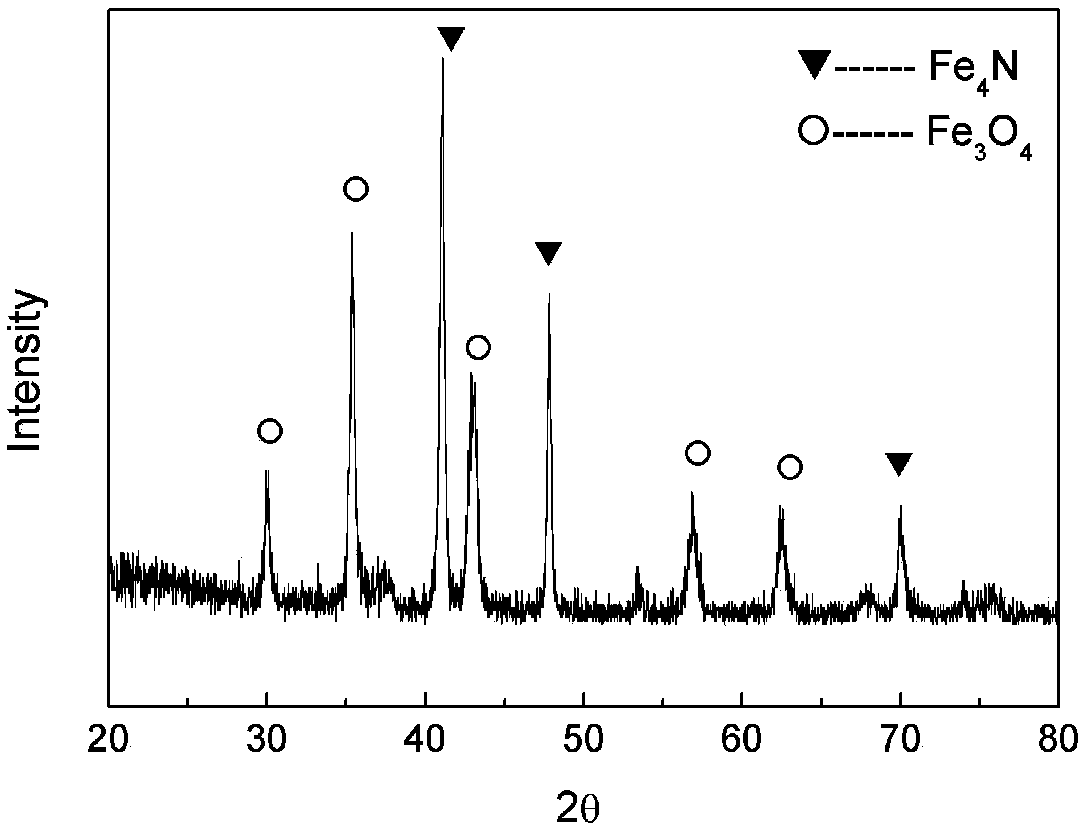

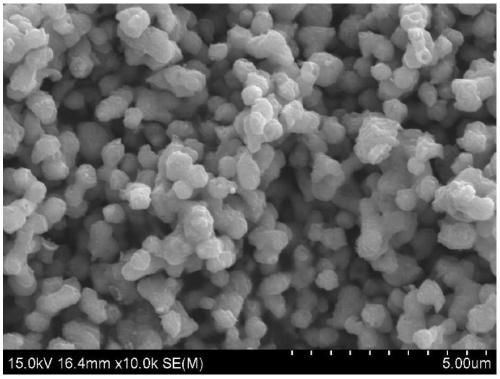

[0039] The preparation method of above-mentioned composite wave-absorbing agent, with Fe 2 o 3 The powder is a precursor, which is prepared by a gas nitriding method after coating treatment.

[0040] The Fe 2 o 3 The precursor is prepared by hydrothermal method, and its shape and size are determined by the raw materials and process of hydrothermal synthesis.

[0041] The preparation steps of the hydrothermal method are as follows:

[0042] (1) Prepare FeCl with a concentration of 0.005-0.2mol / L 3 (ferric chloride) or K 3 [Fe(CN) 6 ] (potassium ferricyanide) aqueous solution, preferably adjust the pH value of the solution with ammonia or sodium hydroxide reagent;

[0043] (2) Put the above solution into an autoclave for reaction, the temperature is controlled at 120-180° C., and the holding time is 12-48 hours;

[0044] (3) After the reaction is completed, take out the reaction product after naturally cooling to room temperature, carry out centrifugation, wash (preferab...

Embodiment 1

[0048] The steps of preparing composite wave absorbing agent are as follows:

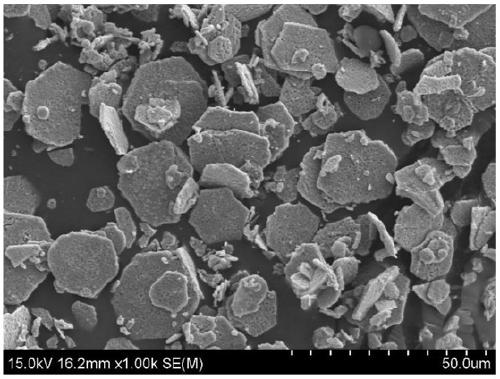

[0049] First, use deionized water to prepare FeCl with a concentration of 0.1mol / L 3 The aqueous solution, the pH value of this aqueous solution is adjusted greater than 14 with sodium hydroxide. Stir at room temperature for 10 minutes to become a clear solution. Pour 70ml of the solution into a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, tighten the lid of the reaction kettle, put the reaction kettle into an oven, and heat at 140°C. Reaction time 12 hours. After naturally cooling to room temperature, the reaction product was taken out, the obtained red precipitate was centrifuged, washed 5 times with deionized water and absolute ethanol, and dried at 60°C to obtain Fe 2 o 3 powder.

[0050] Weigh 1g Fe 2 o 3 Add to a solution of 80ml of absolute ethanol and 16ml of deionized water, and mechanically stir at a low speed for 15min. Then, 2 ml of tetraethyl orthosil...

Embodiment 2

[0053] The steps of preparing composite wave absorbing agent are as follows:

[0054] First, use deionized water to prepare FeCl with a concentration of 0.15mol / L 3 Aqueous solution, pH=2. Pour 70ml of the solution into a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, tighten the lid of the reaction kettle, put the reaction kettle into an oven, and keep the temperature at 150°C for 24 hours. After naturally cooling to room temperature, the reaction product was taken out, the resulting red precipitate was centrifuged, washed with deionized water and absolute ethanol five times each, and dried at 60°C to obtain Fe 2 o 3 powder.

[0055] 2.4g of prepared Fe 2 o 3 Disperse the powder in 100ml of hydrochloric acid (20mmol / L) and stir for 30min, add 5.75g of PVP, and stir for 30min; then add 0.05mol / L aniline solution, and stir the mixture for 1h; according to the formula of ammonium persulfate:aniline=1.1:1 Add ammonium persulfate proportionally, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com