A kind of scale inhibitor for refinery heat exchanger and preparation method thereof

A technology of heat exchangers and scale inhibitors, which is applied in the direction of equipment corrosion/scaling inhibition, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems affecting the finish of equipment and pipelines, corrosion of equipment and pipelines, and influence of finish, etc., to achieve good Effects of biodegradability, adhesion inhibition, and extension of scale inhibition period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

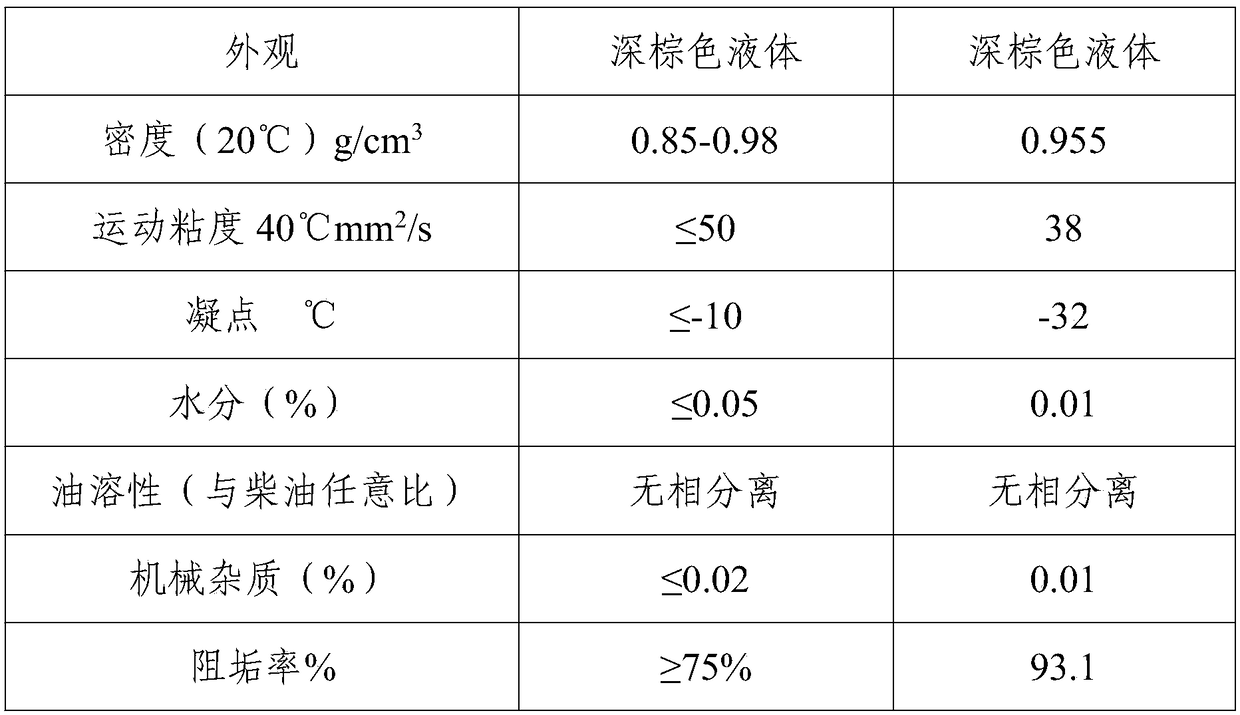

Embodiment 1

[0017] A scale inhibitor for heat exchangers in refineries, made of the following percentages: 12% ashless dispersant, 13% 105 detergent, 1.8% passivator, 3.2% antioxidant, 4% imidazoline, solvent oil margin.

[0018] Among them, the ashless dispersant uses T154 ashless dispersant, the 105 detergent uses T105 synthetic calcium sulfonate detergent with a medium alkali value, the passivator uses 1201 metal passivator, and the antioxidant uses T501 antioxidant.

[0019] The imidazoline adopts oil-soluble imidazoline, and the preparation steps of oil-soluble imidazoline are as follows: weigh oleic acid and polyamine according to a certain proportion and blend them, stir and heat at 150°C for 1.2h, then vacuumize, and continue at 220°C Insulate and react for 1.8 hours, then cool to 70°C, slowly add 0.8 times the volume of ethylene oxide alcohol solution under stirring conditions, stir and cool to room temperature, then stir under water bath conditions for 0.5 hours, and cool to obt...

Embodiment 2

[0022] A scale inhibitor for heat exchangers in refineries, made of the following percentages: 14% ashless dispersant, 12% 105 detergent, 2% passivator, 3.5% antioxidant, 4.5% imidazoline, solvent oil margin.

[0023] Among them, the ashless dispersant uses T154 ashless dispersant, the 105 detergent uses T105 synthetic calcium sulfonate detergent with a medium alkali value, the passivator uses 1201 metal passivator, and the antioxidant uses T501 antioxidant.

[0024] The imidazoline adopts oil-soluble imidazoline, and the preparation steps of oil-soluble imidazoline are as follows: Weigh oleic acid and polyamine according to a certain proportion and blend, stir and heat at 150°C for 1.4h, then vacuumize, and continue at 230°C Insulate and react for 2.1 hours, then cool to 70°C, slowly add 1.2 times the volume of ethylene oxide alcohol solution under stirring conditions, stir and cool to room temperature, then stir for 1 hour under water bath conditions, and cool to obtain oil-...

Embodiment 3

[0027] A scale inhibitor for heat exchangers in refineries, made of the following percentages: 13% ashless dispersant, 10% 105 detergent, 1.7% passivator, 4% antioxidant, 6% imidazoline, solvent oil margin.

[0028] Among them, the ashless dispersant uses T154 ashless dispersant, the 105 detergent uses T105 synthetic calcium sulfonate detergent with a medium alkali value, the passivator uses 1201 metal passivator, and the antioxidant uses T501 antioxidant.

[0029] The imidazoline adopts oil-soluble imidazoline, and the preparation steps of oil-soluble imidazoline are as follows: Weigh oleic acid and polyamine according to a certain proportion and blend, stir and heat at 150°C for 1.5h, then vacuumize, and continue at 220°C Insulate and react for 2.2 hours, then cool to 70°C, slowly add 1.4 times the volume of ethylene oxide alcohol solution under stirring conditions, stir and cool to room temperature, then stir for 1 hour under water bath conditions, and cool to obtain oil-so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com