Method for manufacturing defect-free clad layer at surface of cast iron

A cladding layer and defect-free technology, which is applied in the field of laser technology and coating preparation, can solve the problems of prolonging gas overflow time and affecting work efficiency, etc., and achieve the effect of solving pore defects, reducing scanning speed and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

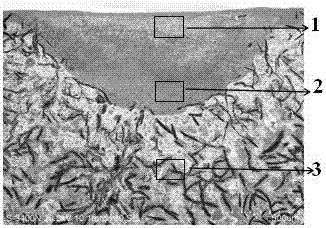

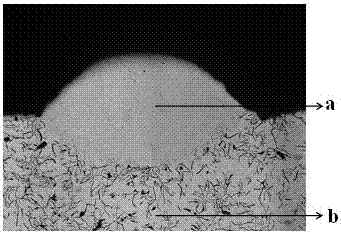

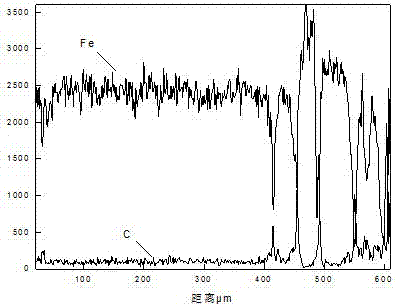

Image

Examples

Embodiment 1

[0028] A method for preparing a defect-free cladding layer on a cast iron surface, comprising the following steps:

[0029] 1. Sample pretreatment; first wire cut the cast iron substrate into 45×35×10m 3 After removing the sample, grind it to 800# with sandpaper, ultrasonically clean it in acetone solution for 10 minutes, rinse it with deionized water, and dry the sample with a blower with cold air;

[0030] 2. Perform laser remelting treatment on the pretreated sample; the process parameters of laser remelting are: laser power P is 400W, scanning speed V is 30mm / min, spot diameter D is 2mm, overlapping rate M is 30%, The focal length H is 209mm, and the protective airflow L is 6L / min;

[0031] 3. Repeat step 2 for secondary laser remelting treatment;

[0032] 4. Select nickel-based alloy powder as the cladding material. The content of each component of the nickel-based alloy powder is as follows: Si content 1.8-3.0 Wt%, Cr content 0-6.0 Wt%, B content 0.8-1.2 Wt%, Fe conten...

Embodiment 2

[0036] A method for preparing a defect-free cladding layer on a cast iron surface, comprising the following steps:

[0037] 1. Sample pretreatment; first wire cut the cast iron substrate into 45×35×10m 3 After removing the sample, grind it to 800# with sandpaper, ultrasonically clean it in acetone solution for 10 minutes, rinse it with deionized water, and dry the sample with a blower with cold air;

[0038] 2. Perform laser remelting on the pretreated sample; the process parameters of laser remelting are: laser power P is 1000W, scanning speed V is 400mm / min, spot diameter D is 3mm, overlap rate is 40%, focal length H is 200mm, and the protective airflow L is 15L / min;

[0039] 3. Repeat step 2 for secondary laser remelting treatment;

[0040] 4. Select iron-based alloy powder as the cladding material. The content of each component of the iron-based alloy powder is as follows: Si content 2.5-7.5%, Cr content 3-6%, B content 1.3-2.0%, C content 0.15-0.75% , the Ni content is...

Embodiment 3

[0044] A method for preparing a defect-free cladding layer on a cast iron surface, comprising the following steps:

[0045] 1. Sample pretreatment; first wire cut the cast iron substrate into 45×35×10m 3 After removing the sample, grind it to 1500# with sandpaper, ultrasonically clean it in acetone solution for 15 minutes, rinse it with deionized water, and dry the sample with a blower with cold air;

[0046]2. Perform laser remelting on the pretreated sample; the process parameters of laser remelting are: laser power P is 1600W, scanning speed V is 240mm / min, spot diameter D is 2mm, overlapping rate is 50%, focal length H is 209mm, and the protective airflow L is 15L / min;

[0047] 3. Repeat step 2 for secondary laser remelting treatment;

[0048] 4. Select cobalt-based alloy powder as the cladding material. The content of each component of the cobalt-based alloy powder is as follows: Si content 0.2-0.4 Wt%, Cr content 4-12Wt%, B content 0.8-1.2 Wt%, Fe content 0- 1 Wt%, O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com