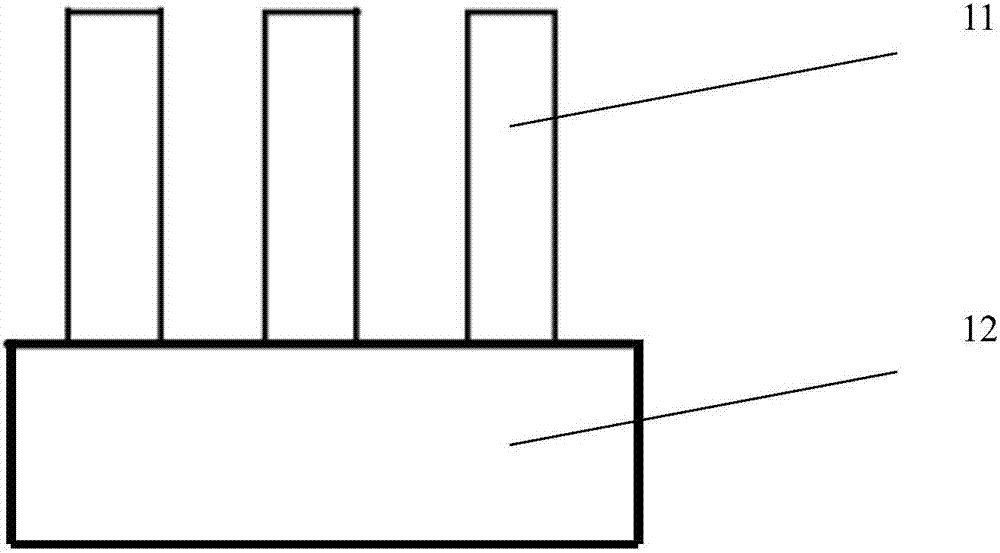

GaN nanometer column grown on Si(111) substrate and preparation method and application thereof

A nano-column and substrate technology, applied in the field of GaN nano-columns, can solve the problems of uneven distribution of GaN nano-columns, large lattice mismatch and thermal mismatch, and uneven diameter length, so as to improve the disorder of column direction, The effect of low defect density and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

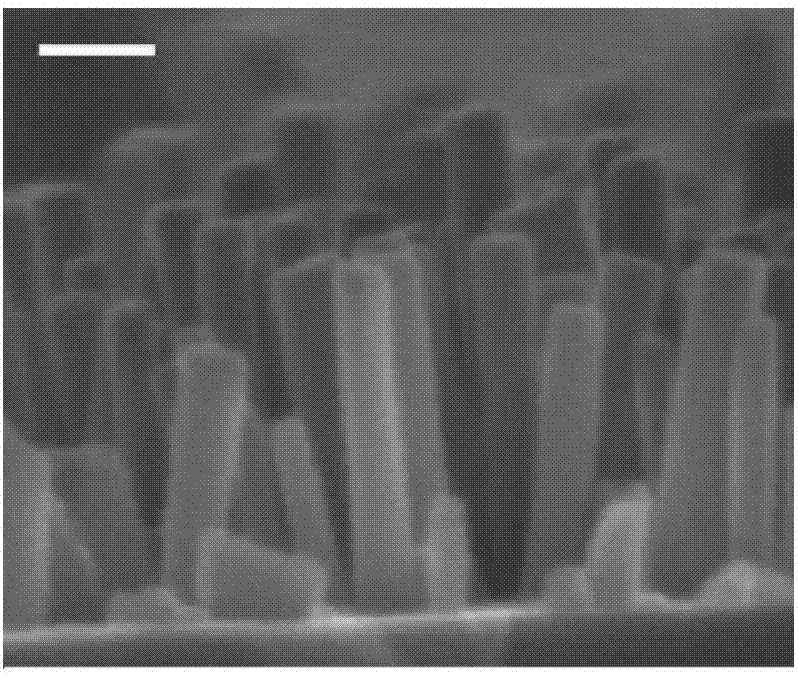

Examples

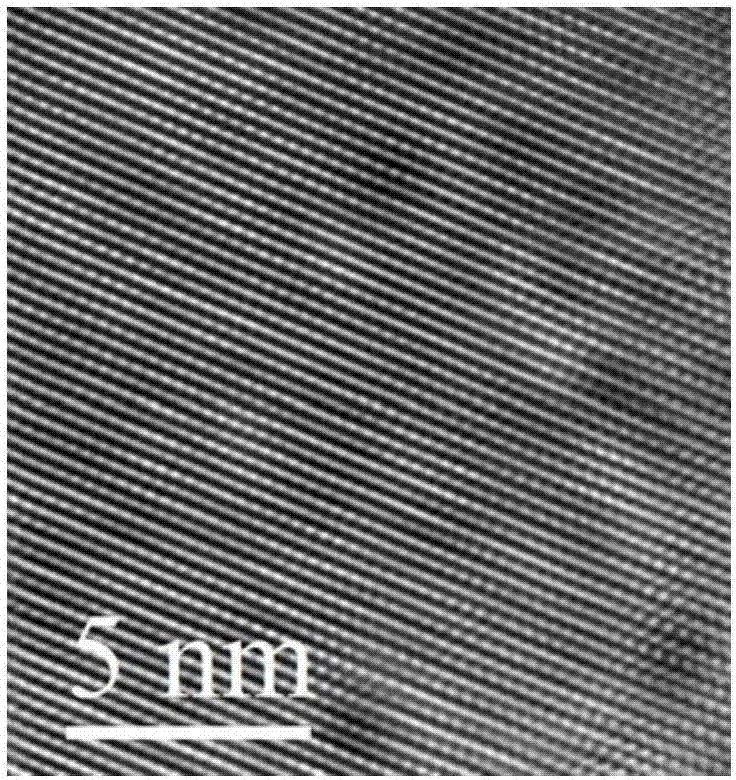

Embodiment 1

[0036] (1) Selection of the substrate and its crystal orientation: Si substrate is used, with the (111) plane as the epitaxial plane, and the crystal epitaxial orientation relationship is: the (0001) plane of GaN is parallel to the (111) plane of Si, that is, GaN ( 0001) / / Si(111), which is helpful for the epitaxial growth of high-quality GaN nanocolumns.

[0037] (2) Surface polishing of the substrate: Polish the surface of the Si substrate with diamond slurry, observe the surface of the substrate with an optical microscope until there are no scratches, and then perform polishing treatment by chemical mechanical polishing.

[0038] (3) Substrate cleaning: standard ultrasonic cleaning of the substrate with a mixture of HF and deionized water at a volume ratio of 1:10 for 1 minute, then repeated washing with deionized water for 1 minute, and finally drying with high-purity dry nitrogen .

[0039] (4) Substrate annealing treatment: transfer the cleaned and dried Si substrate to ...

Embodiment 2

[0044] (1) Selection of the substrate and its crystal orientation: Si substrate is used, with the (111) plane as the epitaxial plane, and the crystal epitaxial orientation relationship is: the (0001) plane of GaN is parallel to the (111) plane of Si, that is, GaN ( 0001) / / Si(111), which is helpful for the epitaxial growth of high-quality GaN nanocolumns.

[0045] (2) Surface polishing of the substrate: Polish the surface of the Si substrate with diamond slurry, observe the surface of the substrate with an optical microscope until there are no scratches, and then perform polishing treatment by chemical mechanical polishing.

[0046] (3) Substrate cleaning: standard ultrasonic cleaning of the substrate with a mixture of HF and deionized water at a volume ratio of 1:10 for 1 minute, then repeated washing with deionized water for 1 minute, and finally drying with high-purity dry nitrogen .

[0047](4) Substrate annealing treatment: transfer the cleaned and dried Si substrate to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com