A kind of composite potassium ferrate slow-release disinfectant and its preparation method and use method

A technology of potassium ferrate and disinfectant, which is applied in the direction of botany equipment and methods, chemical instruments and methods, applications, etc., can solve the problems of bentonite moisture absorption suppression, adsorption performance is easily disturbed, and regeneration is difficult, so as to increase the porosity Efficiency and specific surface area, convenient detection and replacement of reagents, and improvement of overall adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

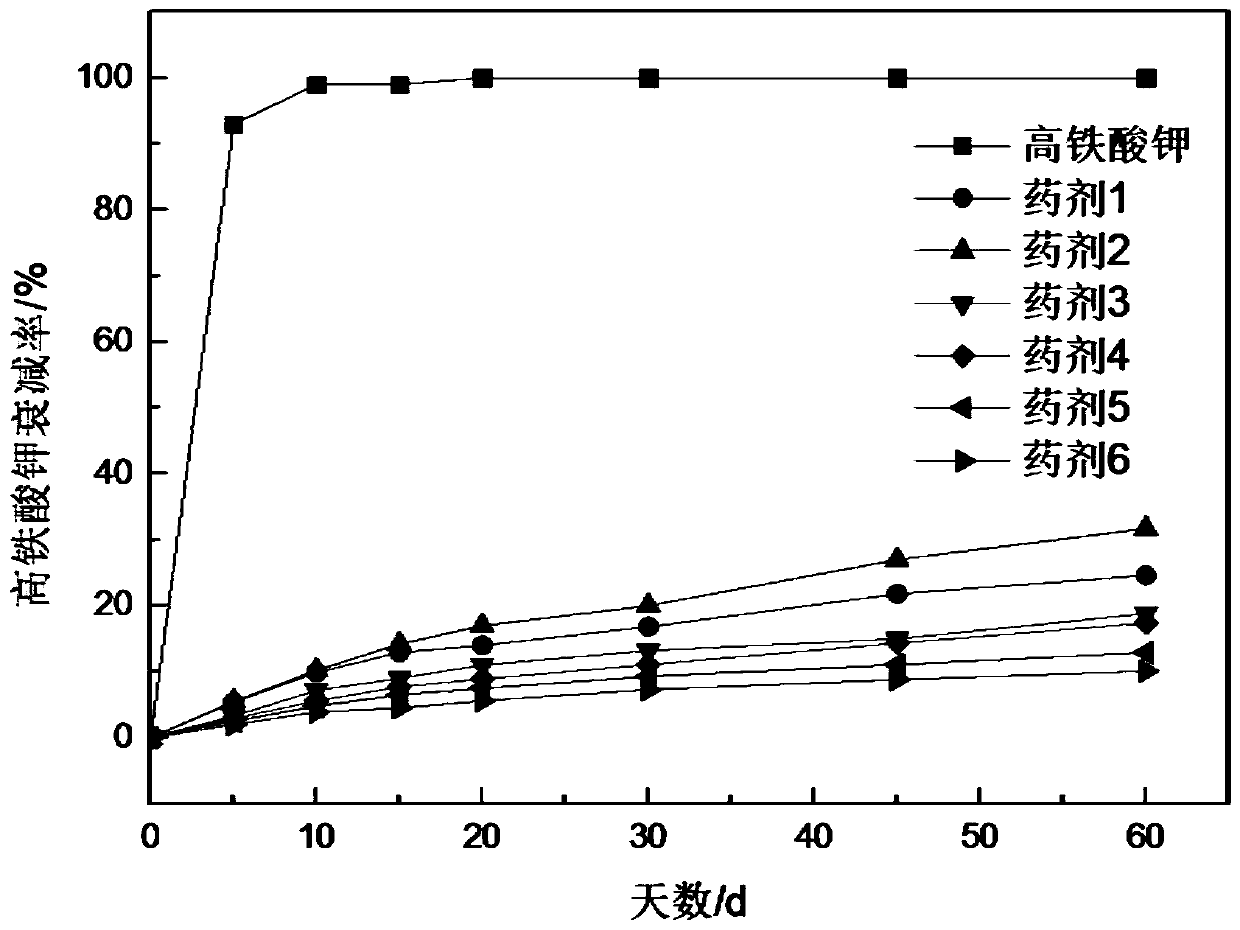

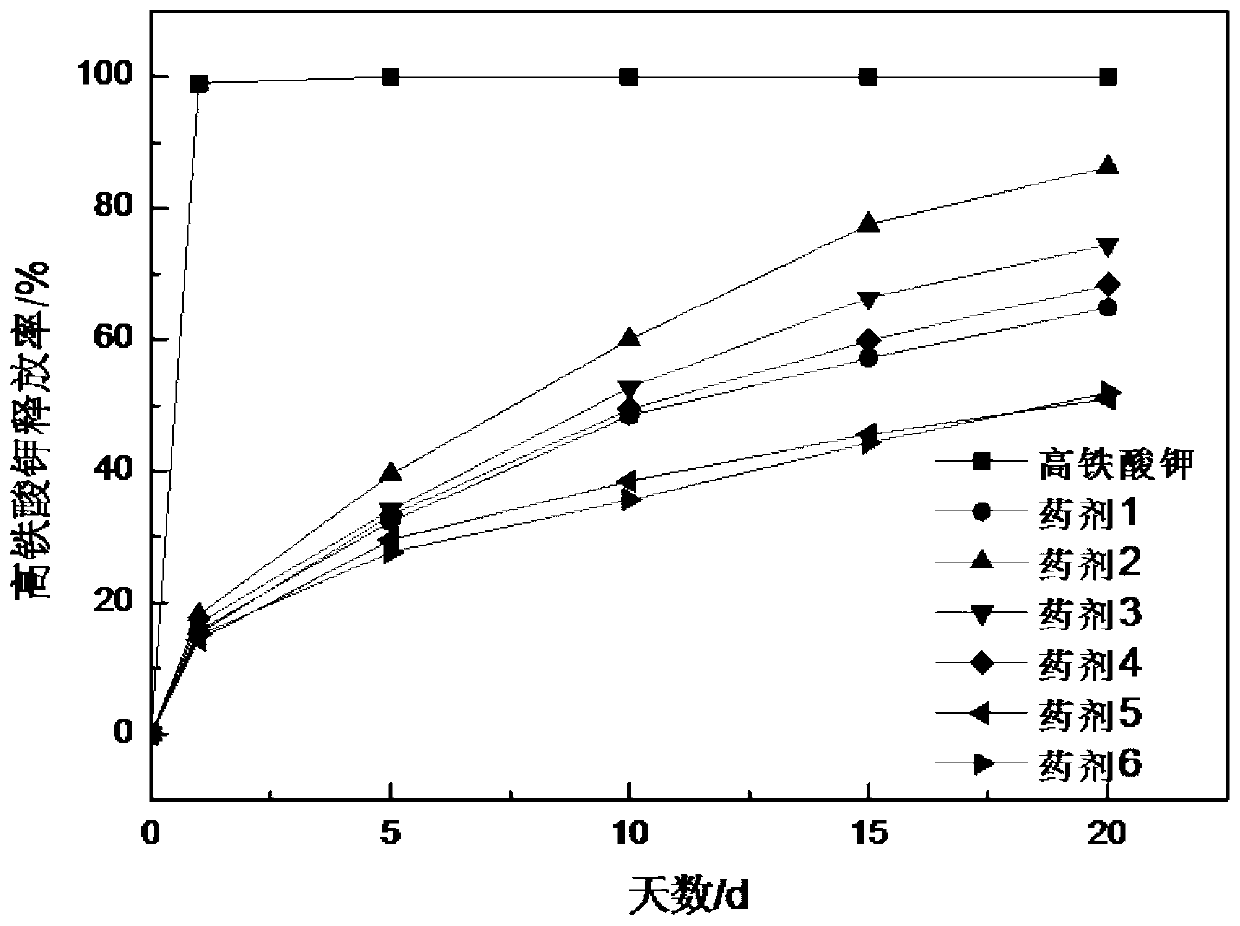

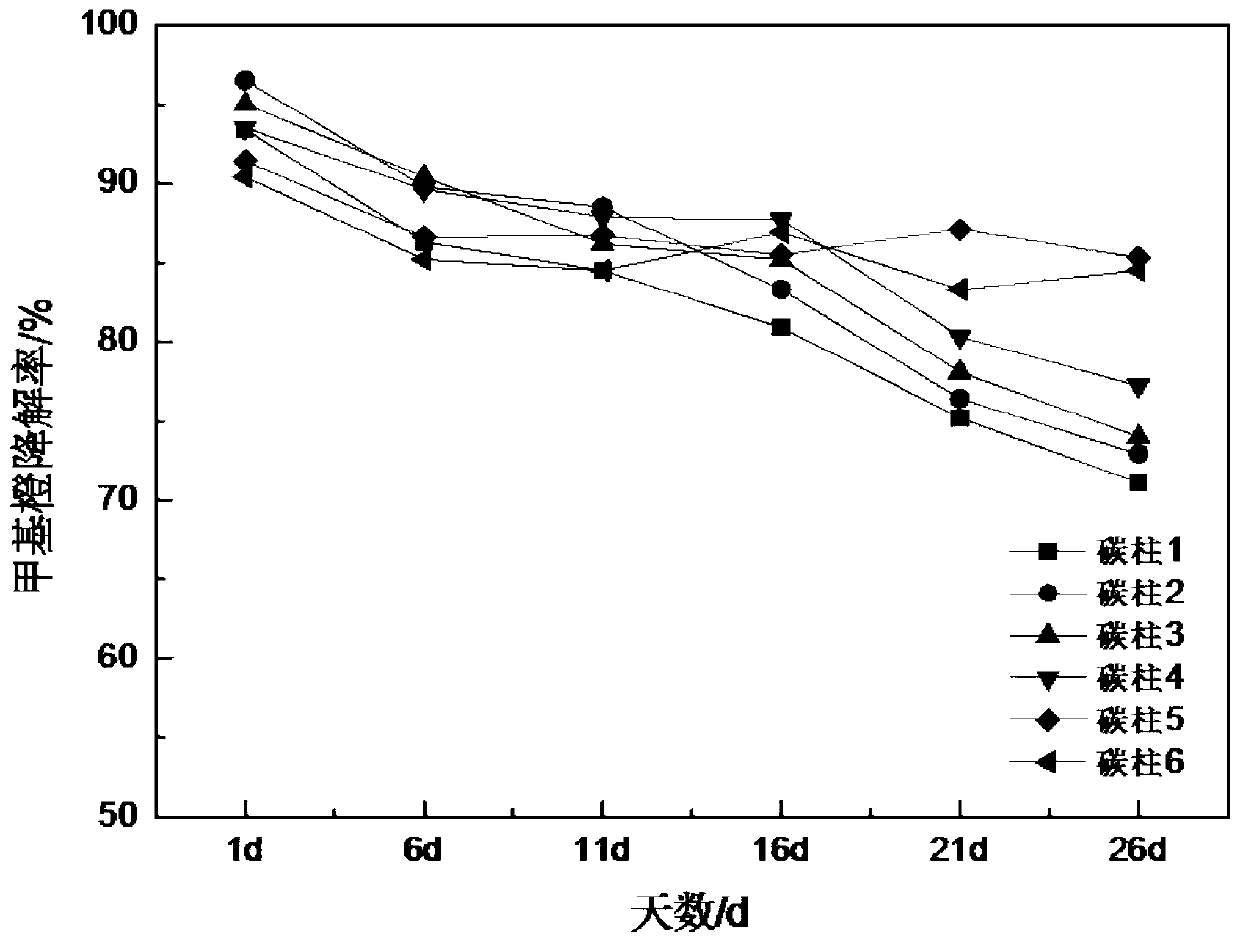

Examples

Embodiment 1

[0047] Raw materials: industrial grade calcium-based bentonite, 20 parts of commercially available sodium hydroxide, 10 parts of potassium hydroxide, 10 parts of calcium hypochlorite, ferric nitrate, 2 parts of n-hexane, 1 part of isopropanol, 1 part of ether, β- Cyclodextrin, 10 parts of epichlorohydrin, 20 parts of carboxymethyl cellulose, the raw materials are divided into 6 groups of medicaments, wherein, the mass ratio of ferric nitrate, bentonite, and β-cyclodextrin is shown in Table 1-1. The steps of release type water treatment agent are:

[0048] Table 1-1 Raw material ratio of sustained-release medicament

[0049]

[0050] According to the ratio of raw materials in the above Table 1-1, the calcium-based bentonites of 6 groups were respectively put into a muffle furnace and roasted at 450°C for 2 hours for modification; Heat to dissolve β-cyclodextrin, raise the temperature to 50°C, drop in epichlorohydrin under full stirring, and finish dropping in about 20 minut...

Embodiment 2

[0058] Raw materials: 110 parts of industrial grade calcium-based bentonite, 20 parts of commercially available sodium hydroxide, 13 parts of potassium hydroxide, 13 parts of calcium hypochlorite, 16 parts of iron nitrate, 3 parts of n-hexane, 2 parts of isopropanol, 1 part of ether 300 parts, 300 parts of β-cyclodextrin, 15 parts of epichlorohydrin, 30 parts of carboxymethyl cellulose, the steps of preparing slow-release water treatment agent are:

[0059] The calcium-based bentonite according to the above ratio is put into a muffle furnace and roasted at 450°C for 2 hours for modification; add β-cyclodextrin to 20% sodium hydroxide aqueous solution, slightly heat to dissolve the β-cyclodextrin, and raise the temperature To 60°C, add epichlorohydrin dropwise under full stirring, and drop it in about 30 minutes. Continue to keep warm and stir to react. The viscosity of the mixture gradually increases until the reaction stops when a gel-like solid appears. The white solid obtai...

Embodiment 3

[0065] Raw materials: 120 parts of industrial grade calcium-based bentonite, 20 parts of commercially available sodium hydroxide, 15 parts of potassium hydroxide, 15 parts of calcium hypochlorite, 18 parts of iron nitrate, 4 parts of n-hexane, 2 parts of isopropanol, 2 parts of ether 200 parts, 200 parts of β-cyclodextrin, 20 parts of epichlorohydrin, 40 parts of carboxymethyl cellulose, the steps of preparing slow-release water treatment agent are:

[0066]The calcium-based bentonite according to the above ratio is put into a muffle furnace and roasted at 450°C for 2 hours for modification; add β-cyclodextrin to 20% sodium hydroxide aqueous solution, slightly heat to dissolve the β-cyclodextrin, and raise the temperature To 70°C, add epichlorohydrin dropwise under full stirring, and drop it in about 30 minutes. Continue to keep warm and stir to react. The viscosity of the mixture gradually increases until the reaction stops when a gel-like solid appears. Wash the product alter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com