Desensitizer for treating dentin hypersensitivity and preparation method thereof

A desensitizer and allergy technology, applied in the field of dental biomedical materials, can solve the problems of no biological activity and antibacterial and bacteriostatic effect, harm to human health of teeth, and affect the aesthetics of teeth, etc., and achieve good biocompatibility and biological activity. , easy to promote, does not affect the effect of dental aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation that is used for bioactive glass-sodium alginate-phosphate desensitization agent, the steps are as follows:

[0041] (1) Preparation of micro-nano bioactive glass spheres of Si-Ca-P ternary system: Dissolve 2g of dodecylamine in 100mL of ethanol-deionized water mixed solution (volume ratio of ethanol to deionized water is 4:1 ), then add ethyl orthosilicate (16.00mL, 72mol), triethyl phosphate (1.64mL, 9.6mmol) and calcium nitrate tetrahydrate (10.04g, 43.2mmol) in sequence, the feeding interval is 30min, stir well , the white emulsion was obtained, and the temperature of the whole process was controlled at 30°C; the obtained white emulsion was centrifuged, and the precipitate was dried at 60°C for 24 h, and then heated at 600°C for 180 min to obtain the Si-Ca-P ternary system Nano bioactive glass spheres;

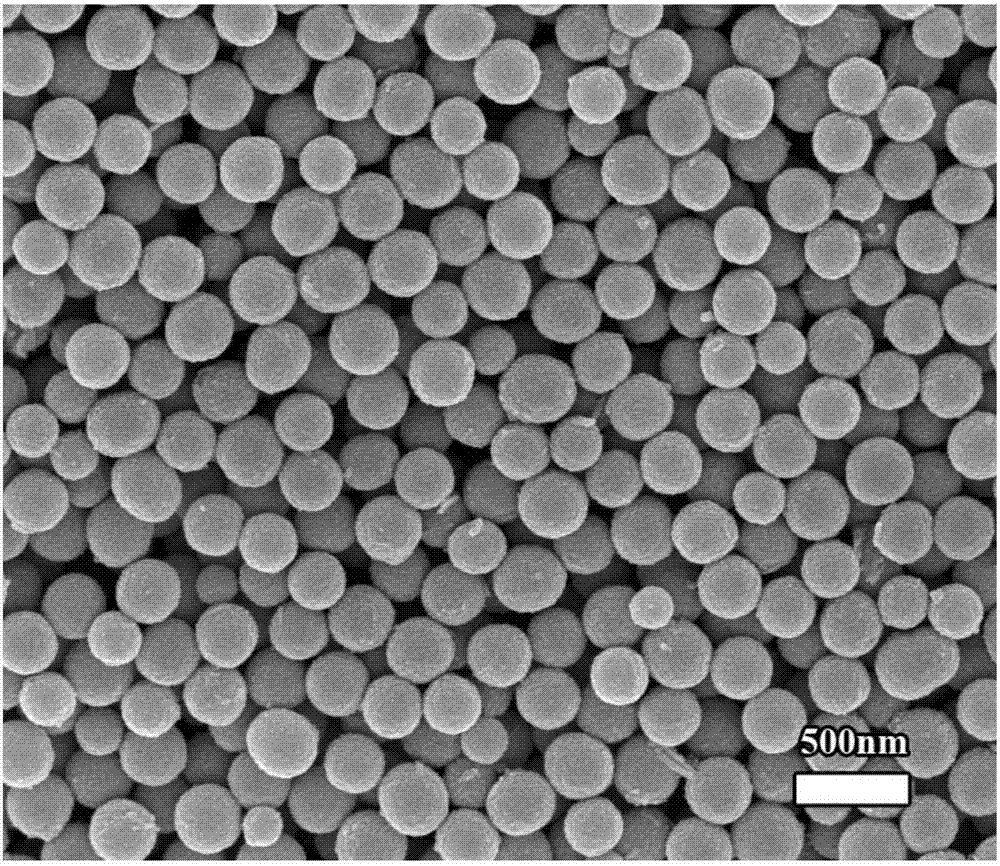

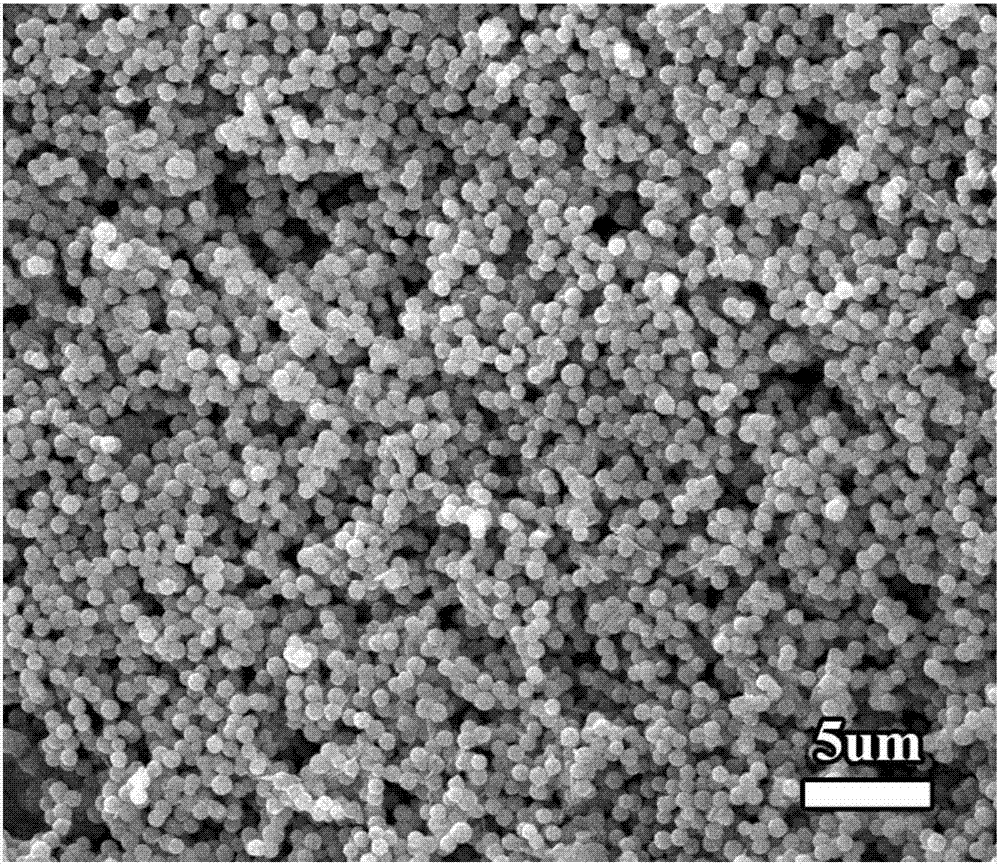

[0042] The SEM pictures of the obtained Si-Ca-P ternary system micro-nano bioactive glass spheres are as follows: figure 1 As shown, it is a...

Embodiment 2

[0047] A kind of preparation that is used for bioactive glass-sodium alginate-phosphate desensitization agent, the steps are as follows:

[0048] (1) Preparation of micro-nano bioactive glass spheres of Si-Ca-P ternary system: Dissolve 4g of dodecylamine in 100mL of ethanol-deionized water mixed solution (volume ratio of ethanol to deionized water is 3:1 ), then add ethyl orthosilicate (16.00mL, 72mmol), triethyl phosphate (1.40mL, 8.2mmol) and calcium nitrate tetrahydrate (6.21g, 26.7mmol) in sequence, the feeding interval is 30min, stir well , the white emulsion was obtained, and the temperature of the whole process was controlled at 40°C; the obtained white emulsion was centrifuged, the precipitate was dried at 70°C for 36 h, and then heated at 650°C for 240 min to obtain the Si-Ca-P ternary system Nano bioactive glass spheres;

[0049] For the SEM image of the obtained Si-Ca-P ternary system micro-nano bioactive glass spheres, see figure 1 , the particle size is 700nm; ...

Embodiment 3

[0053] A kind of preparation that is used for bioactive glass-sodium alginate-phosphate desensitization agent, the steps are as follows:

[0054] (1) Preparation of micro-nano bioactive glass spheres of Si-Ca-P ternary system: Dissolve 6g of dodecylamine in 120mL of ethanol-deionized water mixed solution (volume ratio of ethanol to deionized water is 5:1 ), then add ethyl orthosilicate (16.00mL, 72mmol), triethyl phosphate (1.22mL, 3.6mmol) and calcium nitrate tetrahydrate (3.39g, 14.4mmol) in sequence, the feeding interval is 30min, stir well , the white emulsion was obtained, and the temperature of the whole process was controlled at 50°C; the obtained white emulsion was centrifuged, the precipitate was dried at 80°C for 48 h, and then heated at 700°C for 300 min to obtain the Si-Ca-P ternary system Nano bioactive glass spheres;

[0055] For the SEM image of the obtained Si-Ca-P ternary system micro-nano bioactive glass spheres, see figure 1 , the particle size is 1100nm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com